Electric connector

A technology for electrical connectors and contact parts, applied in the direction of connection, fixed connection, circuits, etc., can solve the problems of short-time charging, large current flowing in electrical connectors, and increased current, so as to reduce conductor resistance, increase strength, and reduce metal volume. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

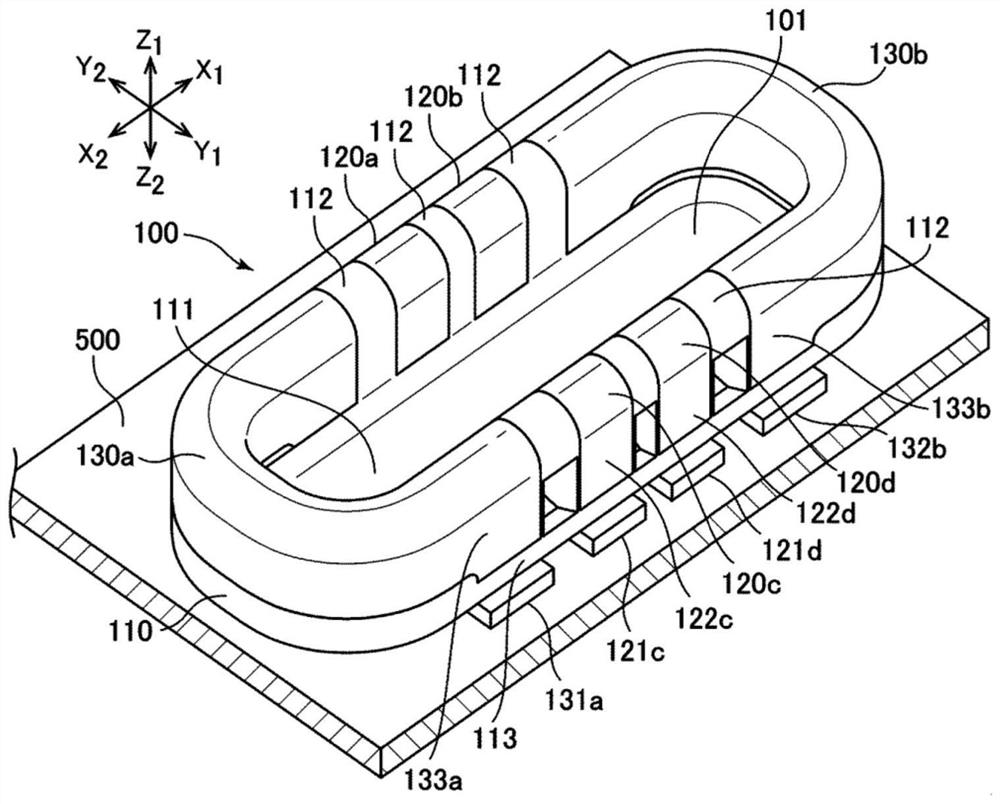

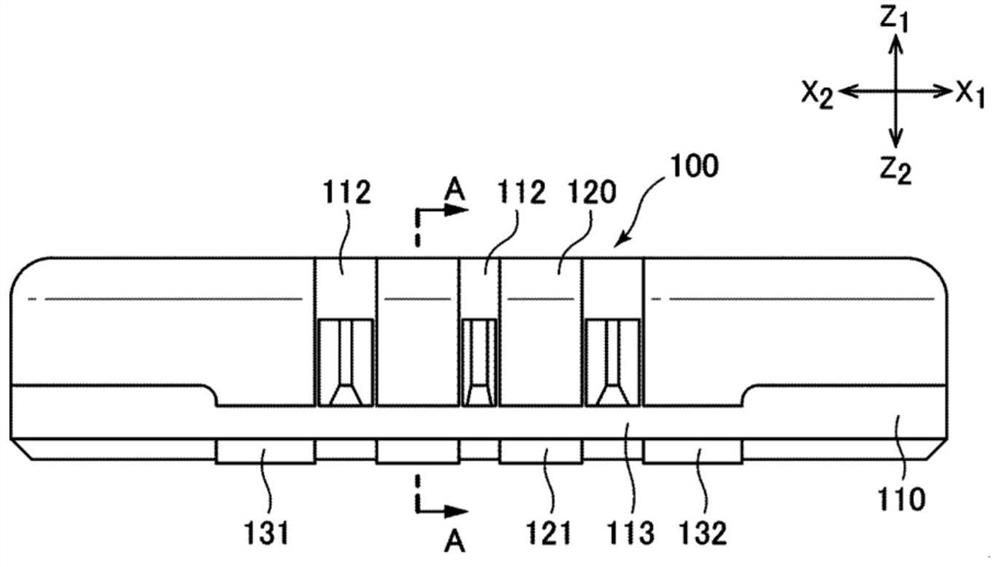

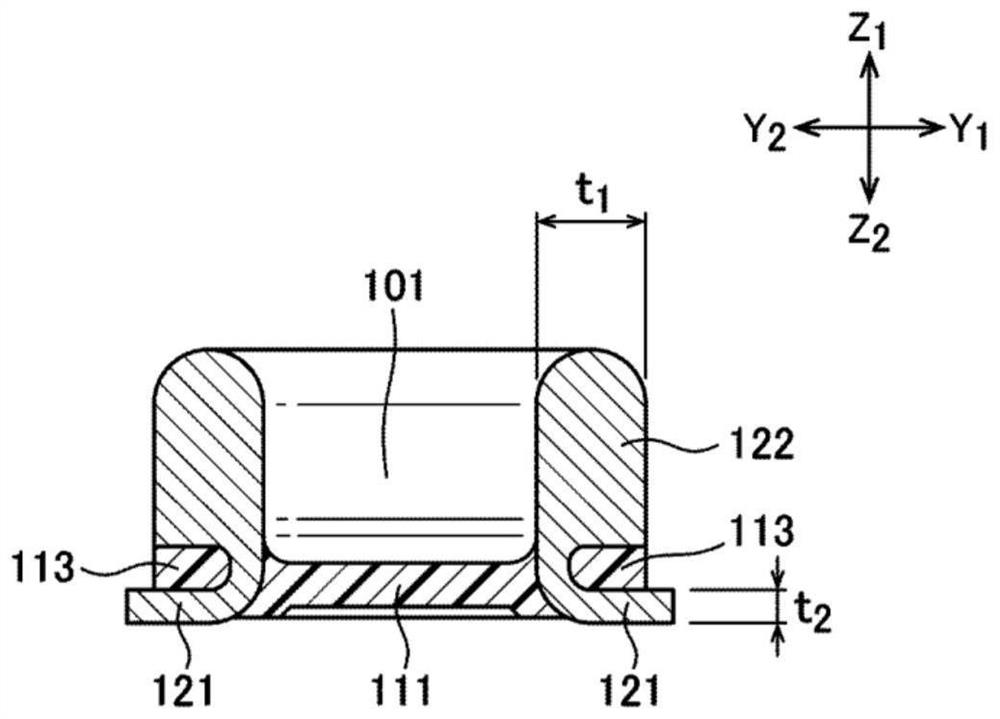

[0042] figure 1 It is a perspective view showing the structure of an electrical connector (plug connector) according to Embodiment 1 of the present invention, figure 2 is the main view, image 3 Yes figure 2 A cross-sectional view of the A-A section. Figure 4 is expressed in figure 1 A perspective view of an electrical connector with only the terminals removed with the housing portion. Figure 5 It is a perspective view which shows the structure of a 1st terminal. Image 6 is to indicate Figure 5 Side view of the structure of the terminal shown. Figure 7 It is a perspective view which shows the structure of a 2nd terminal. Figure 8 is to indicate Figure 7 Side view of the structure of the terminal shown.

[0043] First, according to Figure 1 to Figure 4, the structure of the electrical connector of the first embodiment will be described. The electrical connector according to the first embodiment is a plug connector 100 mounted on a substrate 500 such as a pr...

Embodiment approach 2

[0063] Figure 15 It is a perspective view showing the structure of an electrical connector (plug connector) according to Embodiment 2 of the present invention, Figure 16 is the main view, Figure 17 Yes Figure 16 A cross-sectional view of the B-B section.

[0064] Compared with the above-described first embodiment, the second embodiment of the present invention does not have a recessed portion filled with a part of the housing 210 between the contact portion and the mounting portion of the terminals 220 and 230 . Instead, a part of the housing (the terminal fixing part 213 ) is in close contact with and covers the fitting direction (Z 1 direction) surface. The configuration of the other parts is the same as that of the above-described first embodiment, and therefore, overlapping descriptions are omitted.

[0065]The electrical connector according to the second embodiment is a plug connector 200 mounted on a substrate 500 such as a printed circuit board, and includes an...

Embodiment approach 3

[0069] Figure 18 It is a perspective view which shows the structure of the electrical connector (receptacle connector) which concerns on Embodiment 3 of this invention. Figure 19 It is a perspective view which shows the structure of only a terminal except a case part.

[0070] Figure 20 is a perspective view showing the structure of the terminal, Figure 21 is a side view. Figure 20 and Figure 21 The terminals are used as reinforcing metal parts. In the third embodiment, the present invention is applied to a receptacle connector. Parts other than the terminals 330 (reinforcing metal pieces) are the same as those of a general receptacle connector.

[0071] The electrical connector of the third embodiment is a receptacle connector 300 mounted on a substrate 500 such as a printed circuit board, and includes an insulating housing 310 , four conductive first terminals 320 fixed to the housing 310 , and four conductive first terminals 320 . The conductive second terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com