Method for producing pickled vegetables by combining vacuum tumbling and ultrahigh pressure technology

A technology for pickled vegetables and vegetables, applied in the fields of fruit and vegetable preservation, food science, food preservation, etc., can solve the problems of misuse of food additives, cumbersome process operations, and reduced product brittleness, and achieves small loss of nutrients and rigorous process operations. Reasonable and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

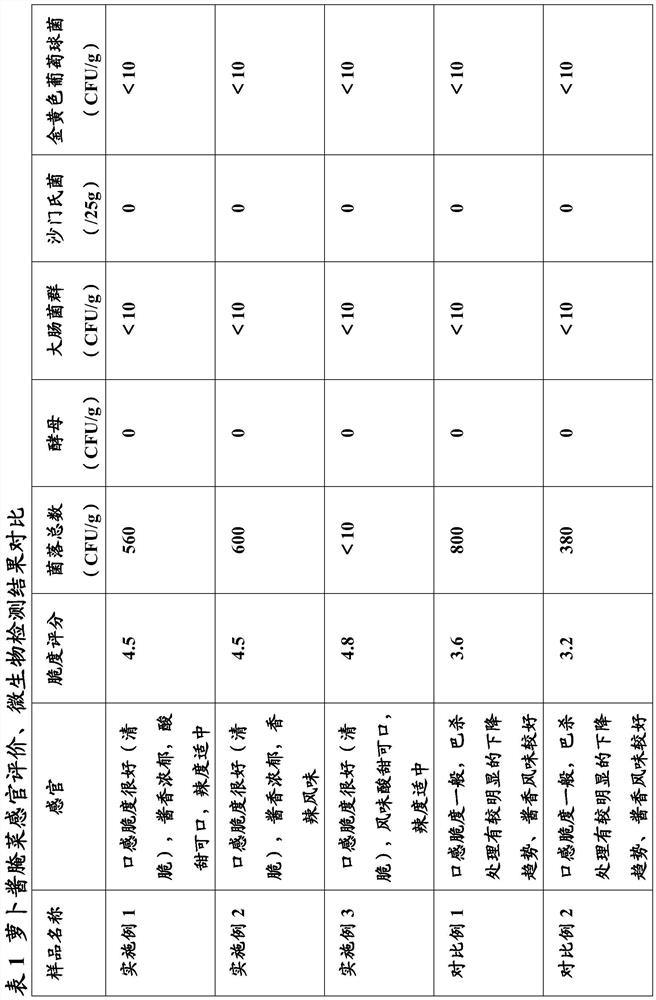

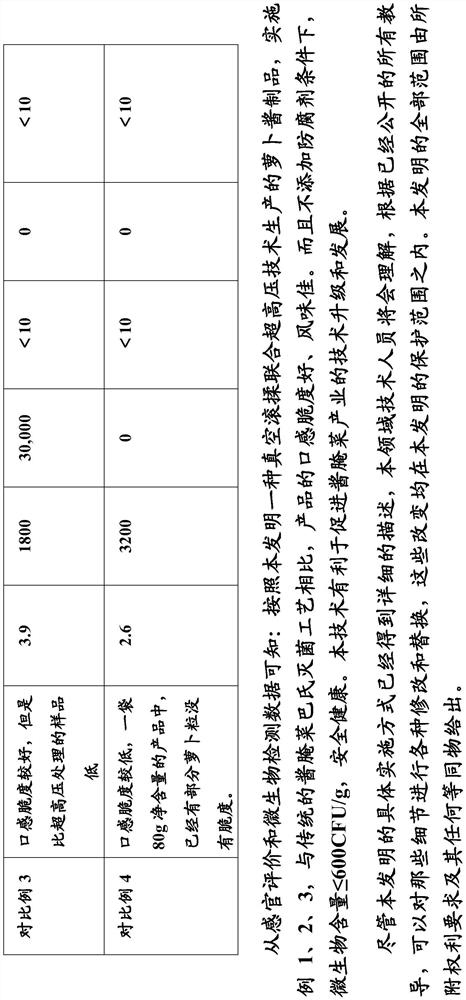

Examples

Embodiment 1

[0031] A kind of radish paste product produced by vacuum rolling and kneading combined ultra-high pressure technology and preparation method thereof, it is characterized by comprising the following steps:

[0032] Radish pretreatment: Fresh white radish is selected, washed, and then cut into flakes, strips or granules for later use.

[0033] Pretreatment of chili, garlic and ginger: remove the stem of fresh chili, clean the chili and garlic, and crush them to 3-5mm for later use; make ginger into pulp and filter to obtain ginger juice for later use; squeeze lemon juice to obtain lemon juice for later use.

[0034] Salting: Add 10% edible salt according to the weight ratio of radish, mix thoroughly, and salt for 5 days under sealed conditions.

[0035] Desalination and dehydration treatment: add water to the pickled radish, soak, wash and desalinate until the sodium chloride content is less than 1.0g / 100g. Then, the water in the radish is removed by centrifugal equipment, and ...

Embodiment 2

[0042] A kind of radish paste product produced by vacuum rolling and kneading combined ultra-high pressure technology and preparation method thereof, it is characterized by comprising the following steps:

[0043] Radish pretreatment: Fresh white radish is selected, washed, and then cut into flakes, strips or granules for later use.

[0044] Pretreatment of chili, garlic and ginger: remove the stem of fresh chili, clean the chili and garlic, and crush them to 3-5mm for later use; make ginger into pulp and filter to obtain ginger juice for later use; squeeze lemon juice to obtain lemon juice for later use.

[0045] Salting: Add 15% edible salt according to the weight ratio of radish, mix thoroughly, and salt for 8 days under sealed conditions.

[0046] Desalination and dehydration treatment: add water to the pickled radish, soak, wash and desalinate until the sodium chloride content is less than 1.0g / 100g. Then, the water in the radish is removed by centrifugal equipment, and ...

Embodiment 3

[0053] A kind of radish paste product produced by vacuum rolling and kneading combined ultra-high pressure technology and preparation method thereof, it is characterized by comprising the following steps:

[0054] Radish pretreatment: Fresh white radish is selected, washed, and then cut into flakes, strips or granules for later use.

[0055] Pretreatment of chili, garlic and ginger: remove the stems of fresh chili, clean the chili and garlic, and crush them to 3-5mm for later use; make ginger into pulp and filter to obtain ginger juice for later use; squeeze lemon juice to obtain lemon juice for later use.

[0056] Salting: Add 20% edible salt according to the weight ratio of radish, mix thoroughly, and salt for 10 days under sealed conditions.

[0057] Desalination and dehydration treatment: add water to the pickled radish, soak, wash and desalinate until the sodium chloride content is less than 1.0g / 100g. Then, the water in the radish is removed by centrifugal equipment, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com