Innovative experience rubbing dyeing machine

A box and steering gear technology, used in typewriters, power transmission devices, printing, etc., can solve the problems of not paying attention to user experience, difficulty in dyeing and weaving with ancient methods, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

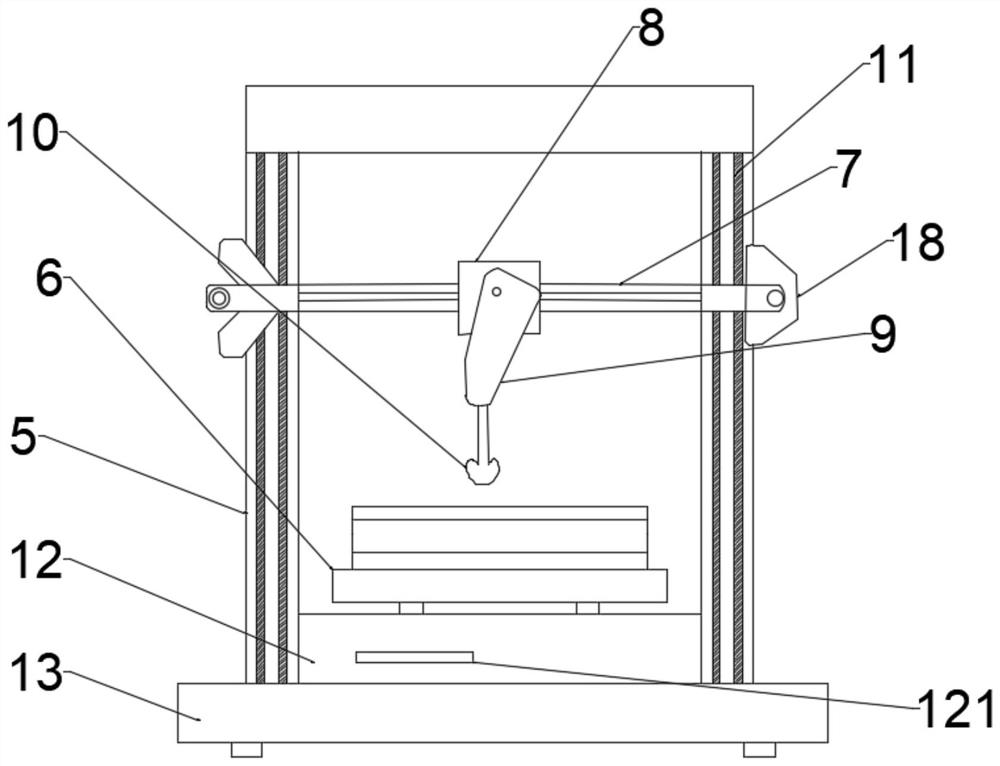

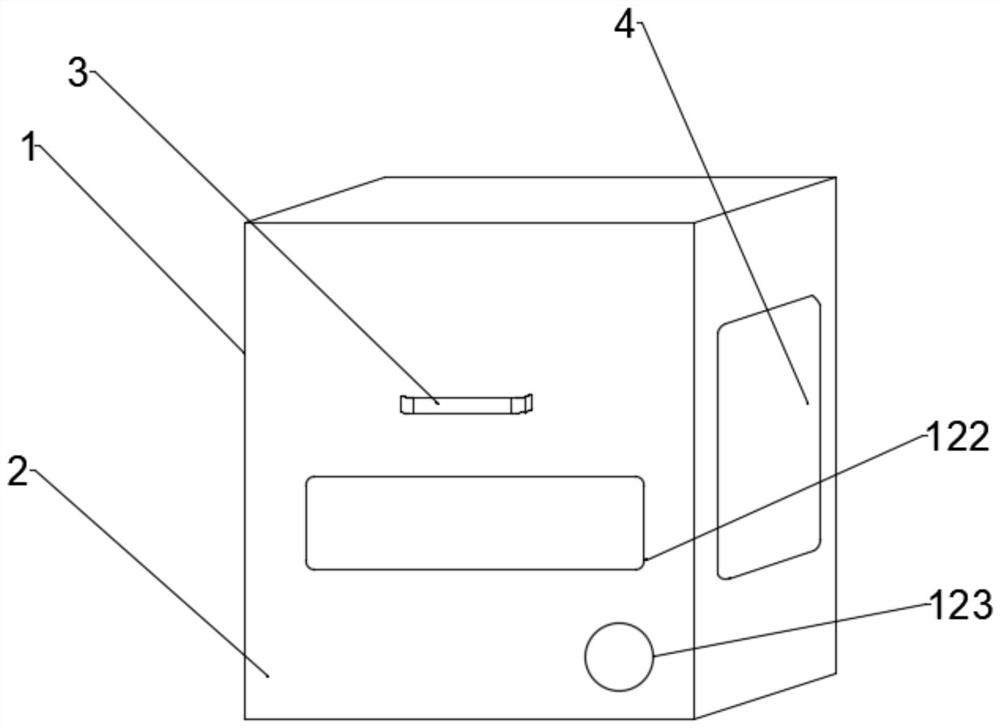

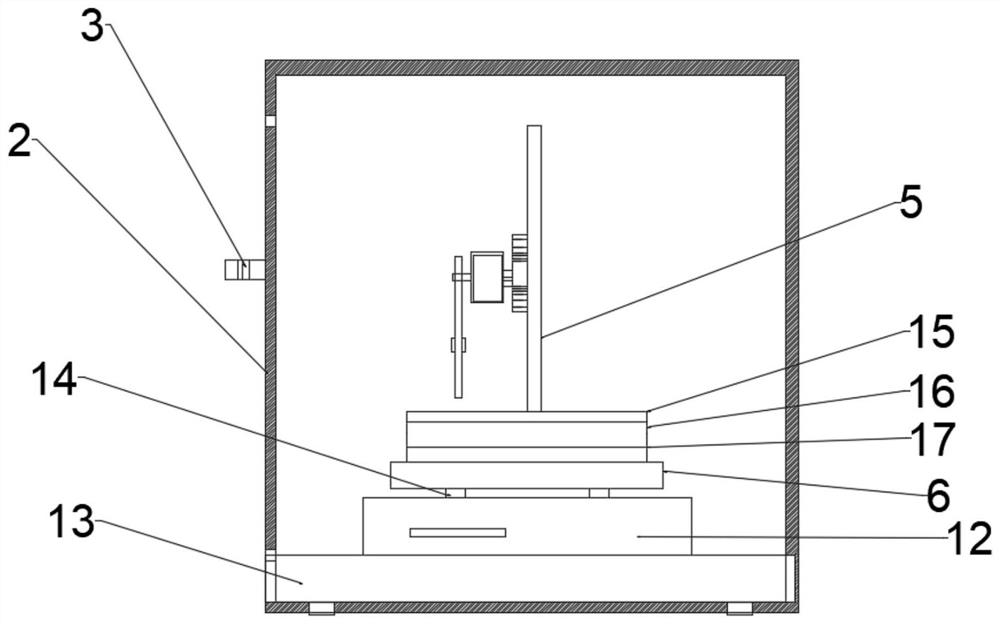

[0031] like Figure 1-3 As shown, this embodiment provides an innovative experience rubbing machine, including a box body 1, a box door 2 is arranged on the side wall of the box body 1, a handle 3 is fixed on the box door 2, and the handle 3 is sleeved There are rubber pads, the inner bottom of the box body 1 is fixed with a base 13 by bolts, the base 13 is slidably provided with a loading platform 6, and the base 13 is provided with a Y-axis transmission assembly, the Y-axis transmission assembly The transmission connection with the loading platform 6 is used to drive the loading platform 6 to slide along the width direction of the base 13 . There is a printing mechanism vertically above the loading platform 6 , and the printing mechanism is the slider 8 , a steering gear 9 and a hammer 10, the steering gear 9 is fixed on one side of the slider 8, the slider 8 is slidably connected to the crossbar 7 away from the steering gear 9, and the steering gear The output end of 9 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com