Overflow valve mechanism with self-cleaning function

A technology of relief valve and cleaning mechanism, applied in the field of hydraulic parts manufacturing, can solve problems such as inability to self-clean, and achieve the effects of avoiding equipment damage, improving adaptability and strength, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

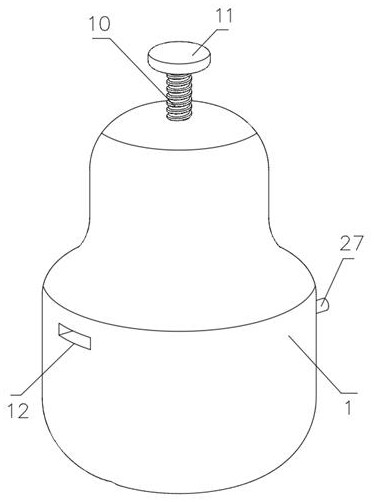

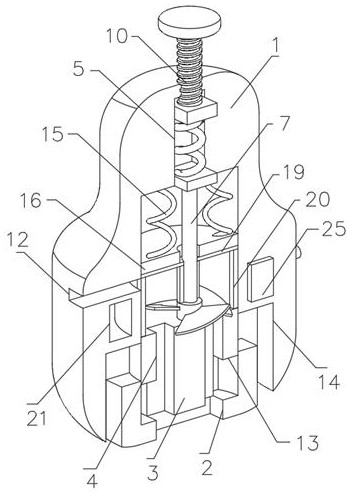

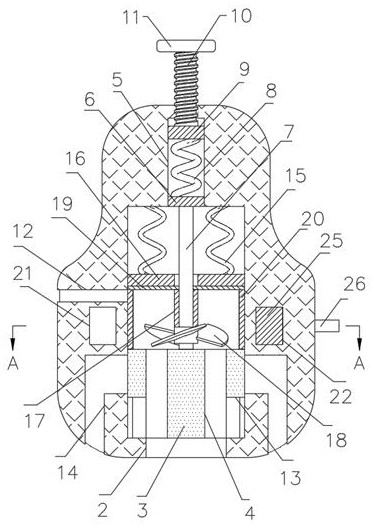

[0022] refer to Figure 1-6 , a relief valve mechanism with self-cleaning function, including a casing 1, an oil inlet 2 is opened through the bottom of the casing 1, the inner wall of the casing 1 is sealed and slidably connected with a valve core 3, and the end of the valve core 3 is opened through There is an oil passage hole 4, a release groove 13 is formed through the side wall of the oil passage hole 4, an oil return port 14 corresponding to the release groove 13 is formed through the side wall of the casing 1, and an outlet is formed through the side wall of the casing 1. The oil port 12, the inner top of the housing 1 is provided with a pressure regulating groove 5, the inner wall of the pressure regulating groove 5 is sealed and slidingly connected with the top plate 6, the bottom of the top plate 6 is fixed with a top rod 7, and the end of the top rod 7 is connected to the valve core 3. The upper end of the top plate 6 is connected with the pressure plate 9 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com