Device for dehydrating veneer

A technology of single plate and rotating plate, which is applied in the direction of drying gas arrangement, progressive dryer, and drying of solid materials without heating. stagnant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

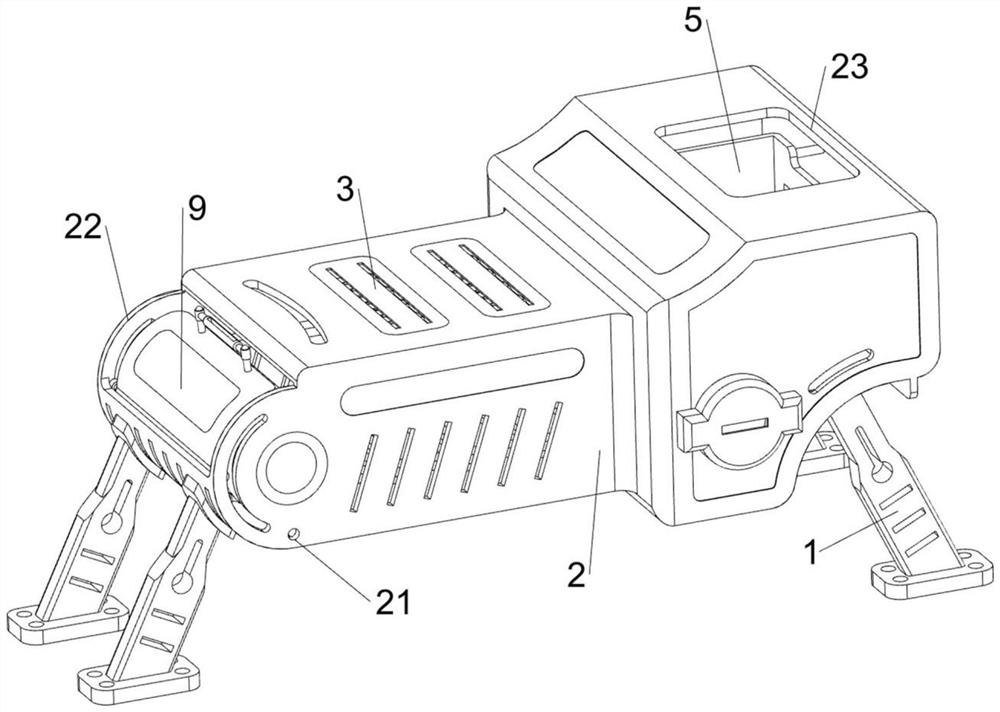

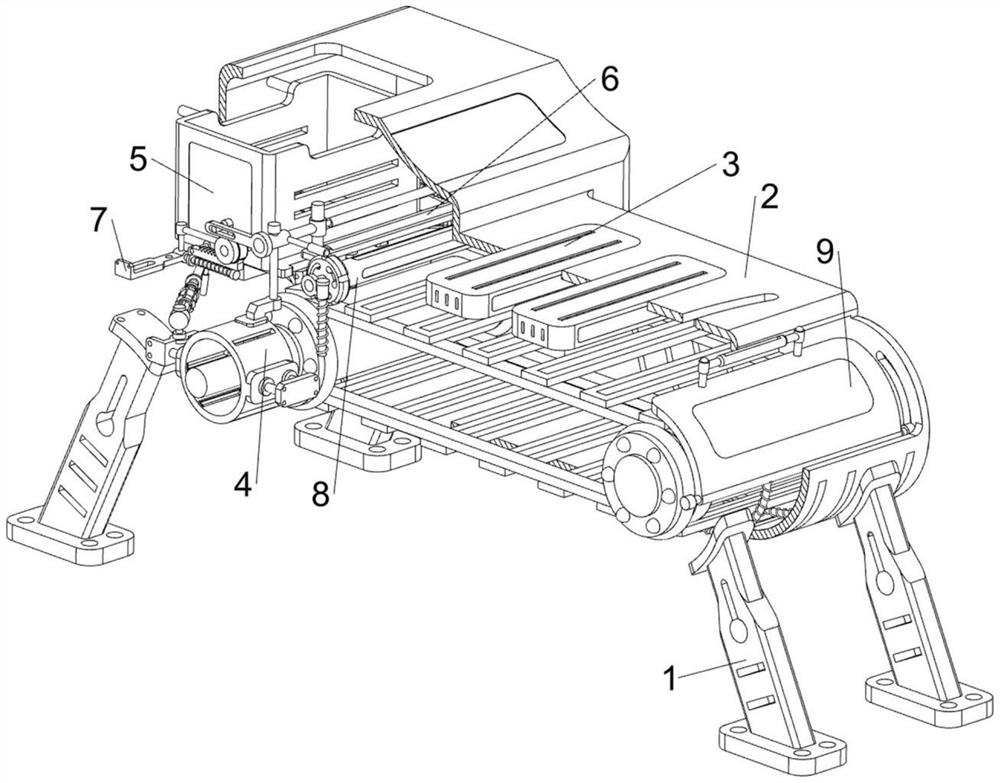

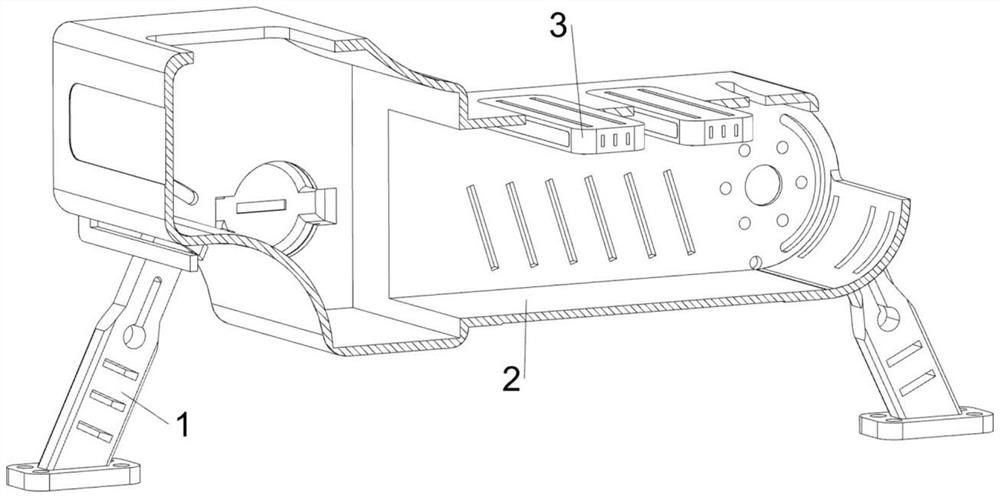

[0036] A device for dehydration of veneers, in Figure 1-3 As shown in the figure, it includes a support rod 1, a protective frame 2, a fan 3, a conveying mechanism 4 and a feeding mechanism 5. The left and right sides of the lower part of the protective frame 2 are symmetrically provided with a supporting rod 1 in the front and rear, and the left side of the top of the protective frame 2 is provided with two A fan 3 capable of drying the veneer, the top right side of the protective frame 2 is provided with a feeding chute 23 for people to put the veneer in, the left side wall of the protective frame 2 is provided with a discharging chute 22, the left side of the protective frame 2 is provided with There are card slots 21 on both sides. The protective frame 2 is provided with a conveying mechanism 4 capable of conveying veneers. A feeding mechanism 5 capable of intermittently pushing veneers is connected between the conveying mechanism 4 and the inner right side of the protecti...

Embodiment 2

[0041] On the basis of Example 1, in figure 2 , Figure 7 and Figure 8 It also includes a wiping mechanism 6. The wiping mechanism 6 includes a guide rod 60, a connecting rod 61, a sponge plate 62 and a return spring 63. The tops of the two support frames 40 are provided with guide rods 60, and two guide rods 60. A connecting rod 61 is slidably provided between the upper side, the bottom of the connecting rod 61 is slidably provided with a sponge plate 62 capable of preliminarily dehydrating the veneer, and a return spring is connected between the front and rear sides of the sponge plate 62 and the interior of the connecting rod 61 63.

[0042] exist figure 2 , Figure 9 and Figure 10 It also includes a transmission mechanism 7, and the transmission mechanism 7 includes a second connecting block 70, a protective frame 71, a connecting shaft 72, a cam 73, a rotating rod 74, a gear 75, a limit rod 76, a rack 77, a return force The spring 78 and the toggle lever 79 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com