Rust-proof treatment device for steel fibers

A technology of anti-rust treatment and steel fiber, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven dipping and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

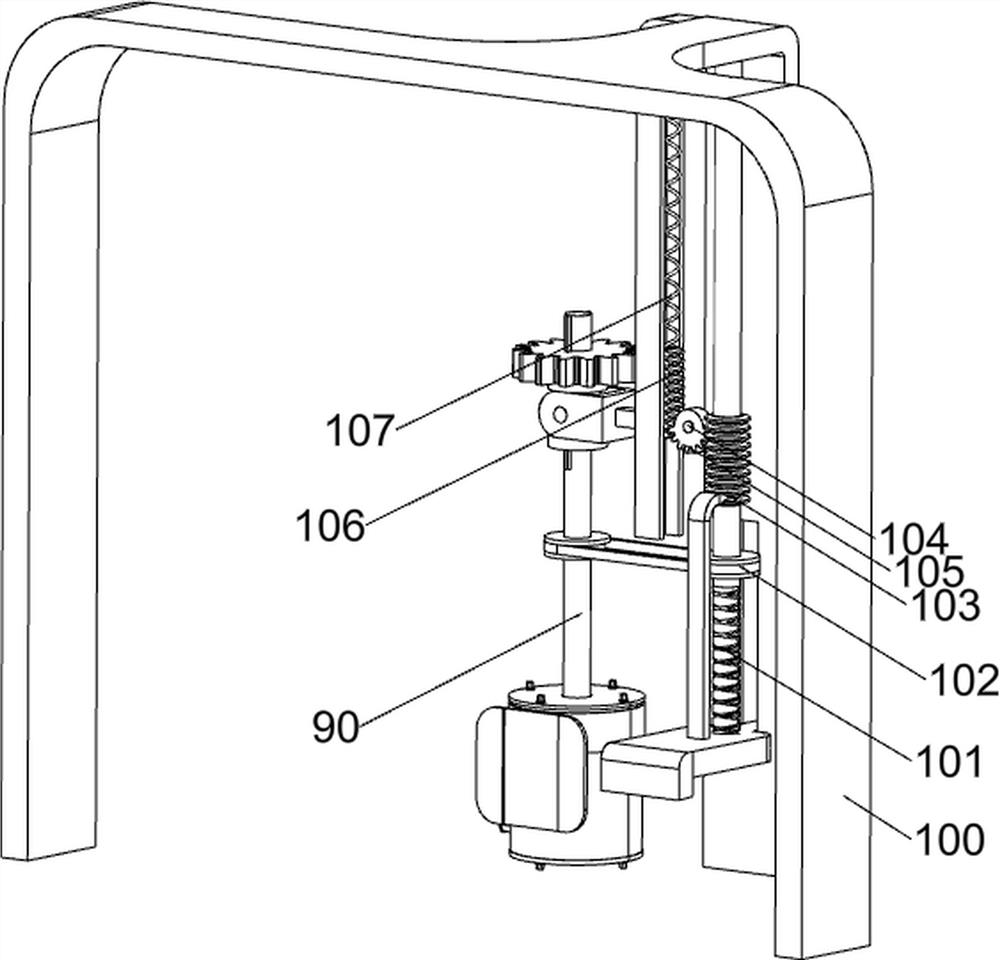

[0084] A rust-proof treatment device for steel fibers, such as Figure 1-3 As shown, including a base 1, a first support frame 2, a servo motor 3, a storage basket 4, a sheet 5, a baffle 6, a separator 7, a leak 13, a transmission mechanism 9, and a unit 10, a base 1. A first support frame 2 is provided on the left side of the top, and the lower portion of the first support frame 2 and the base 1 are provided with a servo motor 3, and there is a storage basket 4 on the top of the base 1, and a baffle is provided on the left side of the storage basket 4. 6, the storage basket 4 is slidably provided with a sheet 5, and a partition plate 7 is provided in the front side of the storage basket 4, and there is a drain network 8 on the top and rear side of the top and rear of the sheet 5. The servo motor 3 and the first support A transmission mechanism 9 is provided between the frame 2, and the opening side is provided with a dial mechanism 10 on the top of the base 1.

[0085] The staff p...

Embodiment 2

[0087] On the basis of Example 1, such as Figure 4-5 As shown, the transmission mechanism 9 includes a first spindle 90, a sleeve 91, a connecting frame 92, a first spring 93, a first gear 94, and a meshing sleeve 95, and the servo motor 3 output is provided with a first axle 90, a first spin. 90 is rotated from the first support frame 2, and the first shaft 90 is actively provided with a sleeve 91, and a connecting frame 91 is provided on the sleeve 91, and the sleeve 91 is provided with a first spring between the first support frame 2. 93, the top rotation of the sleeve 91 is provided with a first gear 94, and the first gear 94 is slidably connected to the first axis 90, and the upper rotation of the first support frame 2 is provided with a meshing sleeve 95, and the engaging sleeve 95 and the first gear 94. Compatible.

[0088] The mover mechanism 10 includes a second support frame 100, a second rotating shaft 101, a first pulley assembly 102, a rack sleeve 103, a first connect...

Embodiment 3

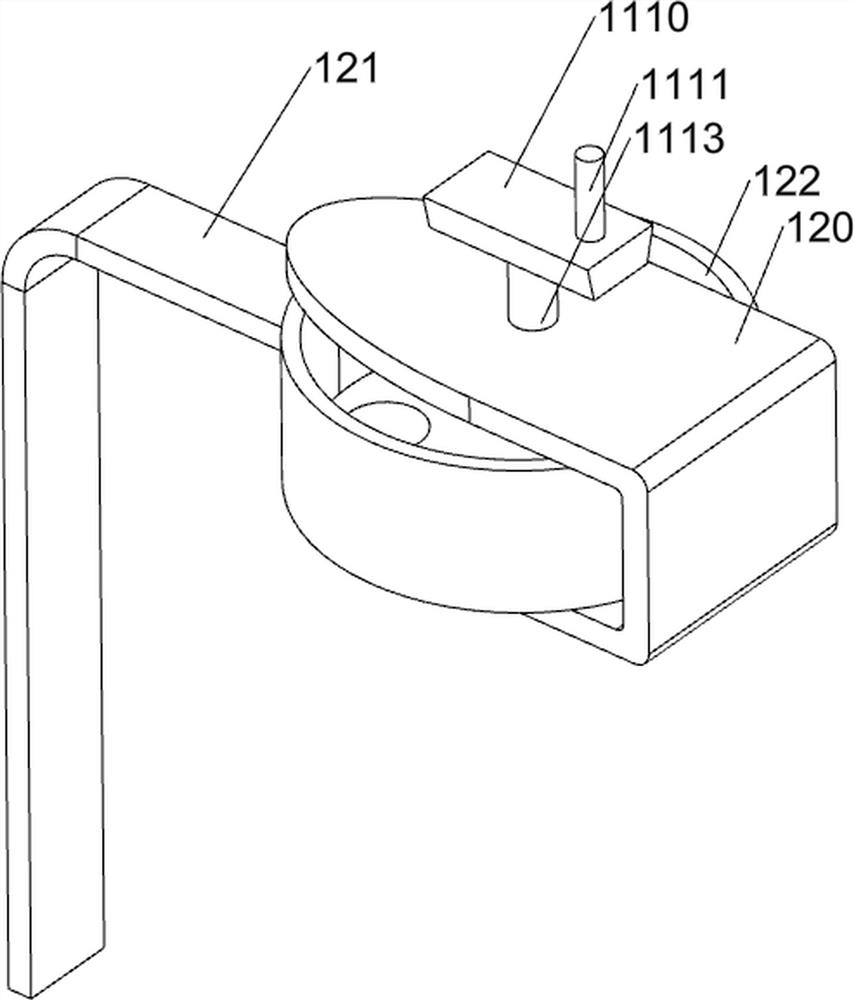

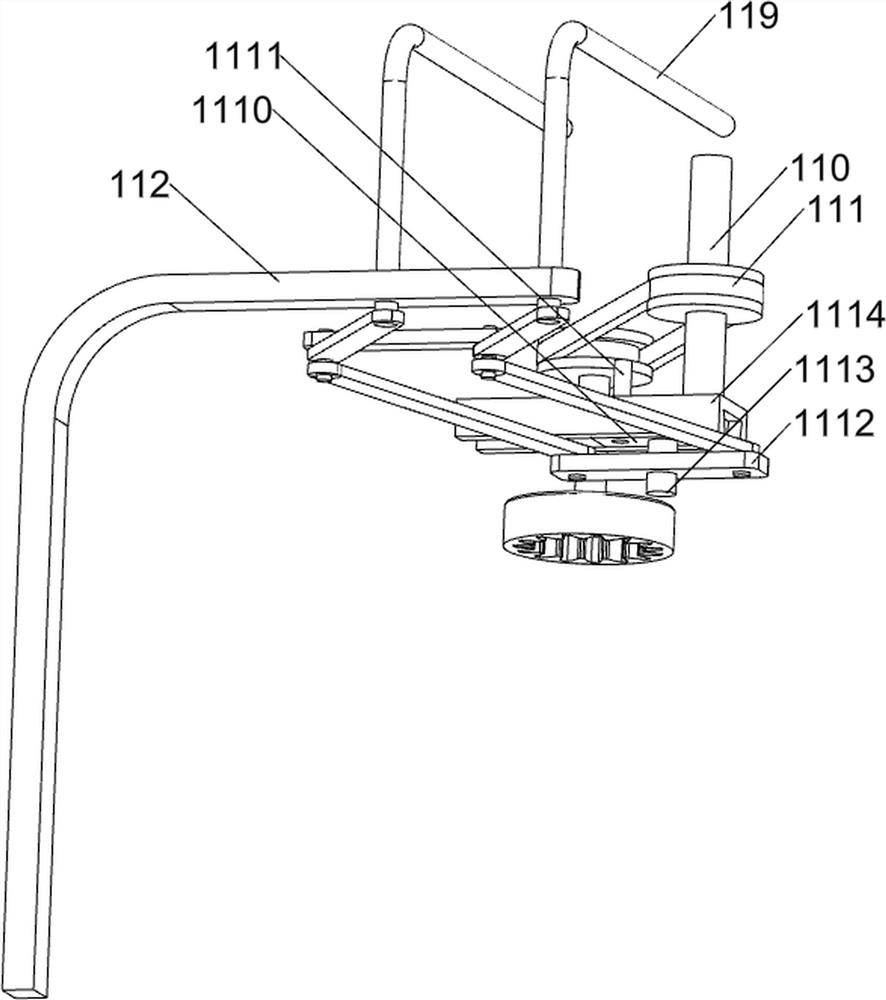

[0091] On the basis of Example 2, such as Figure 6-10 As shown, there is a rotating mechanism 11, and the rotating mechanism 11 includes a third rotating shaft 110, a second pulley assembly 111, a third support frame 112, a first connecting plate 113, a second connecting plate 114, a third connecting plate 115, The second connecting rod 116, the first sliding rail 117, the rail wheel 118, the third connecting rod 119, the slider 1110, the first guide bar 1111, the fourth connection plate 1112, the fourth connection rod 1113 and the connection block 1114, the second The top rotation of the support frame 100 is provided with the third rotating shaft 110, and the third rotating shaft 110 is provided with a second pulley assembly 111 between the transmission shaft of the engaged sleeve 95, and the second pulley assembly 111 consists of two pulley and a belt, two The pulley is connected to the transmission shaft of the third rotating sleeve 95, respectively, and the belt is disposed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com