Concrete slump testing device for building construction

A technology for building construction and testing devices, applied in the directions of measuring devices, instruments, flow characteristics, etc., can solve the problems of high labor intensity, and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

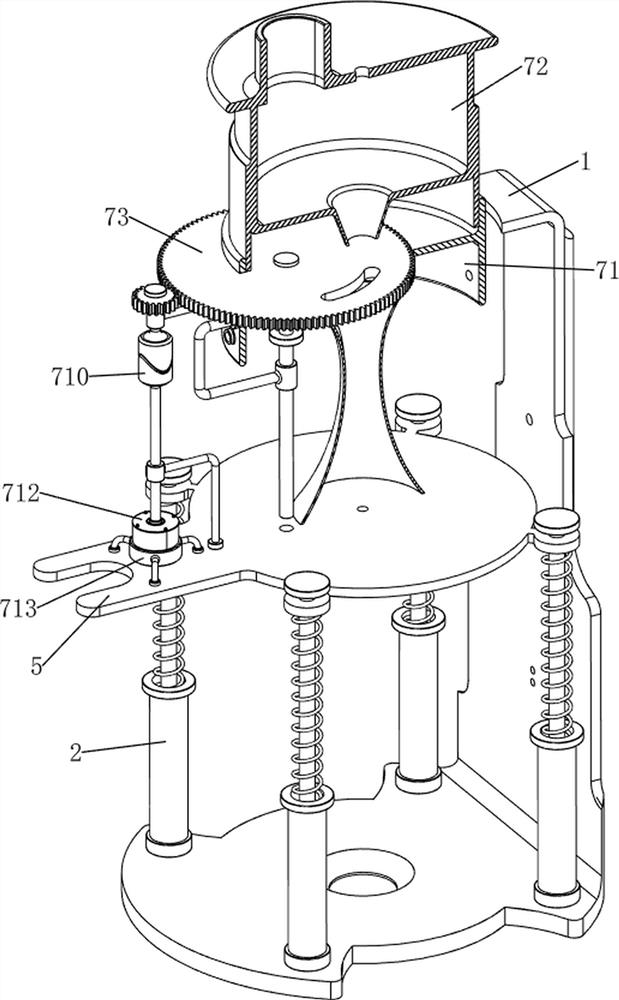

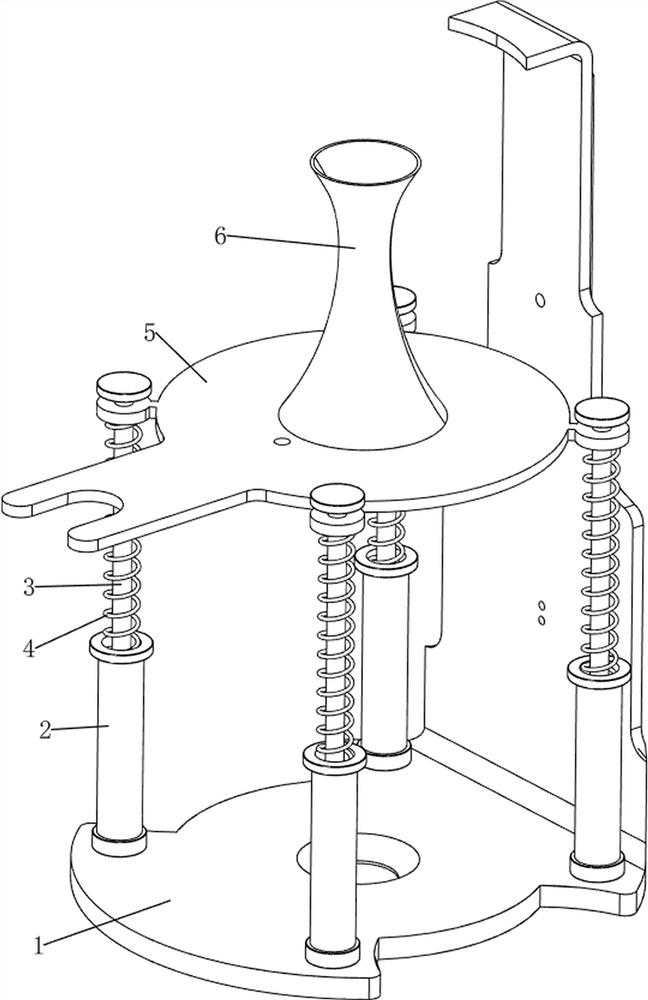

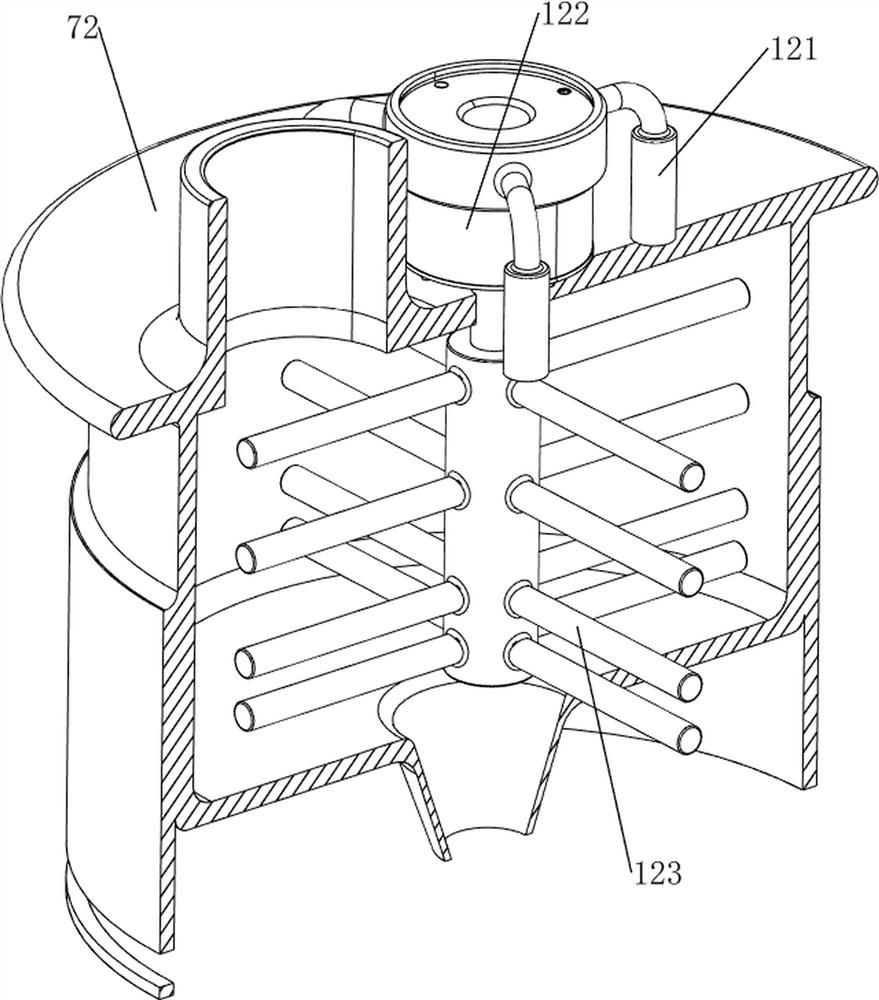

[0035] A construction concrete slump test device, refer to Figure 1-6, including a support frame 1, a support sleeve 2, a first sliding rod 3, a first linear spring 4, a support plate 5, a test cylinder 6, a blanking mechanism 7 and a fixing mechanism 8, and the lower side of the support frame 1 is provided with four The support sleeve 2, the inner side of the support sleeve 2 is slidably provided with a first sliding rod 3, the upper part of the first sliding rod 3 is provided with a support plate 5, and a first linear spring is connected between the support sleeve 2 and the support plate 5 4. A test cylinder 6 for concrete testing is placed on the top of the pallet 5, a blanking mechanism 7 for realizing automatic intermittent unloading is provided between the upper part of the support frame 1 and the pallet 5, and a lower part of the support frame 1 and the pallet 5 are provided. There is a fixing mechanism 8 for limiting the pallet 5, and the upper part of the support fra...

Embodiment 2

[0040] On the basis of Example 1, refer to figure 2 and Figure 7 , and also includes an emptying mechanism 9 for discharging the air in the concrete. The emptying mechanism 9 includes a fifth rotating shaft 91, a limit ring 92, a sixth rotating shaft 93, a flat belt 94, a seventh rotating shaft 95 and an emptying rod 96 There is a limit ring 92 in the middle of the support plate 5, the inner side of the limit ring 92 is rotatably provided with a fifth rotating shaft 91, the upper part of the fifth rotating shaft 91 is located in the second rotating shaft 76 and is slidably connected, and the bottom of the fifth rotating shaft 91 is provided with a sixth rotating shaft 91 Rotating shaft 93, a seventh rotating shaft 95 is rotatably provided in the middle of the right side of the pallet 5, a flat belt 94 is wound between the seventh rotating shaft 95 and the sixth rotating shaft 93 through a pulley, and the upper part of the seventh rotating shaft 95 is provided with an emptyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com