Cable network antenna manufacturing error sensitivity analysis method based on proxy model

A technology for sensitivity analysis and manufacturing error, applied in electrical digital data processing, complex mathematical operations, instruments, etc., can solve the problems of not considering the convergence of sensitivity indicators, insufficient precision of proxy models, and inability to meet both accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

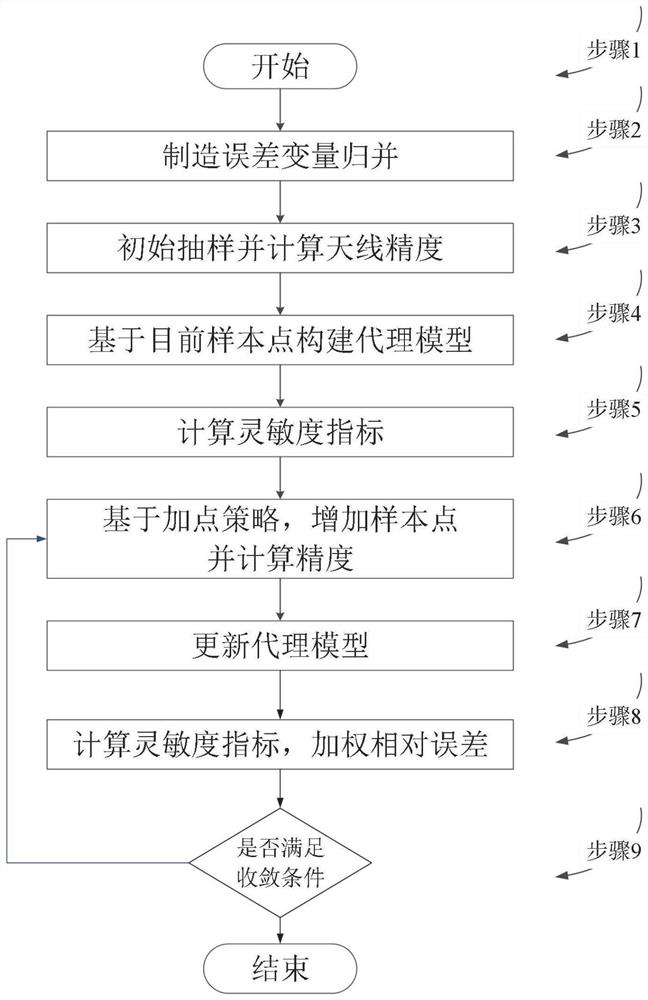

[0051] like figure 1 As shown, a surrogate model-based global sensitivity analysis method at least includes the following steps:

[0052] Step 1: Start with error sensitivity analysis;

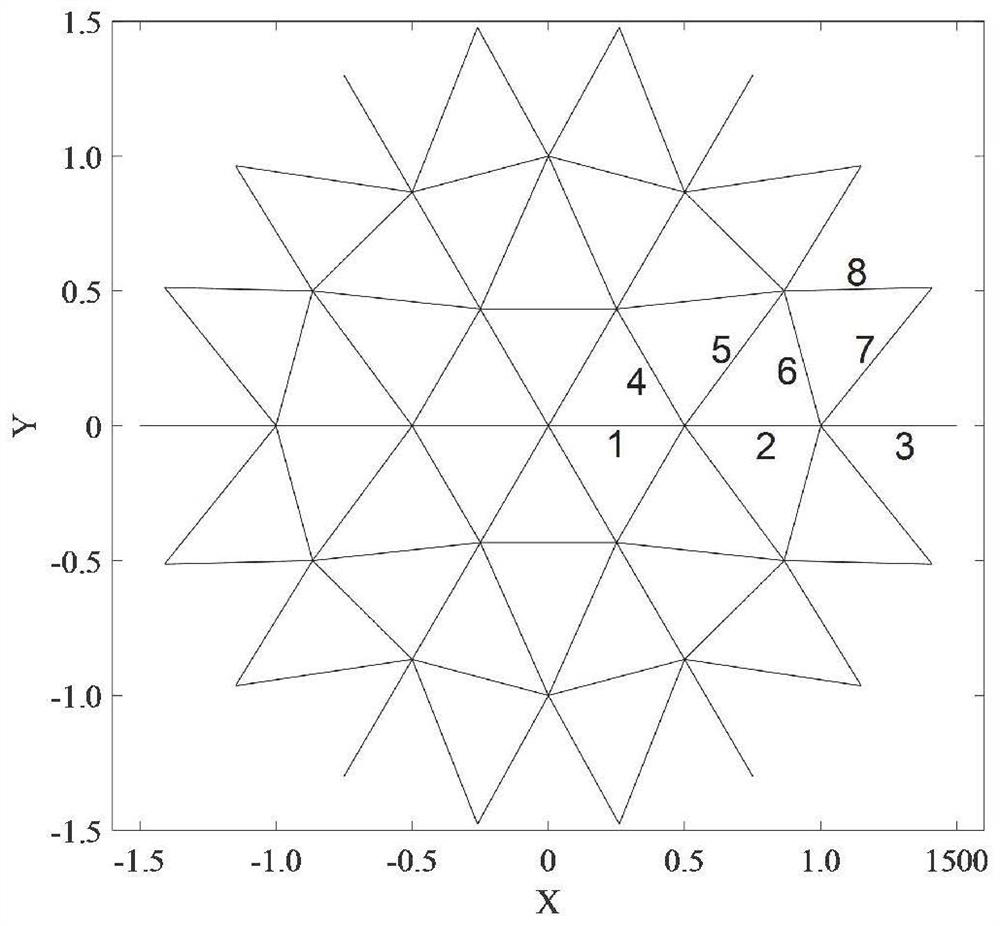

[0053] Step 2: Classify and merge manufacturing error variables according to structural symmetry characteristics; including the following:

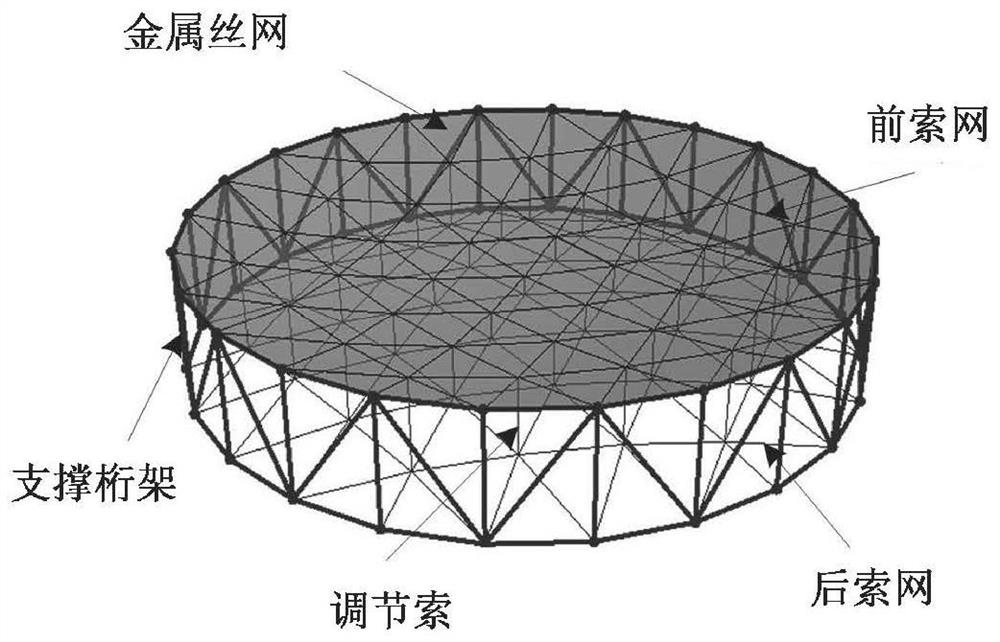

[0054] For the front cable net length error, rear cable net length error, adjustment cable length error and boundary point position error of the cable net antenna, according to the position of the cable segment or boundary point associated with the error, and according to the symmetry of the cable net antenna, the above The four error types are merged and classified into n categories.

[0055] Step 3: Initially sample the manufacturing error and calculate the corresponding antenna accuracy; including the following steps:

[0056] Step 3a: According to the size of the error variable n in the specific cable network antenna, according to N initial =8n dete...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap