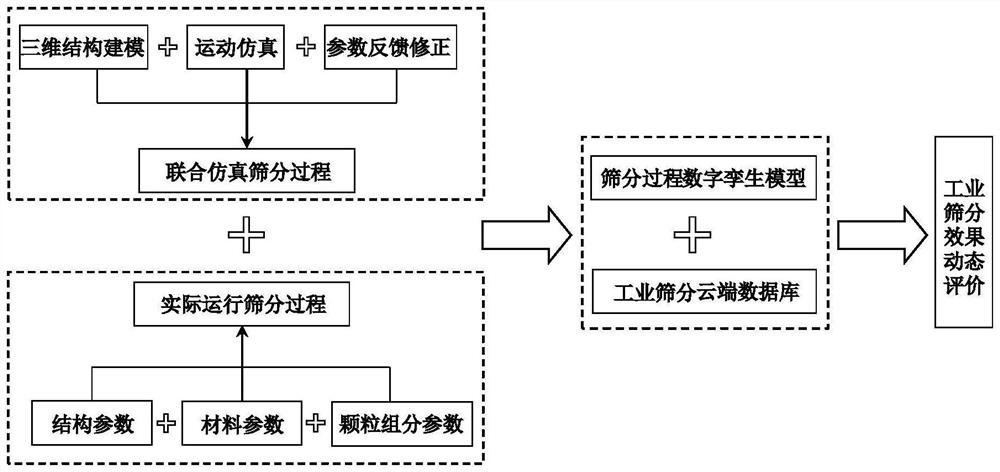

Industrial screening effect dynamic evaluation method based on digital twinning

A technology of industrial screening and evaluation methods, applied in data processing applications, instruments, geometric CAD, etc., can solve the problem of inability to real-time evaluation of industrial screening effects, and achieve the effect of real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

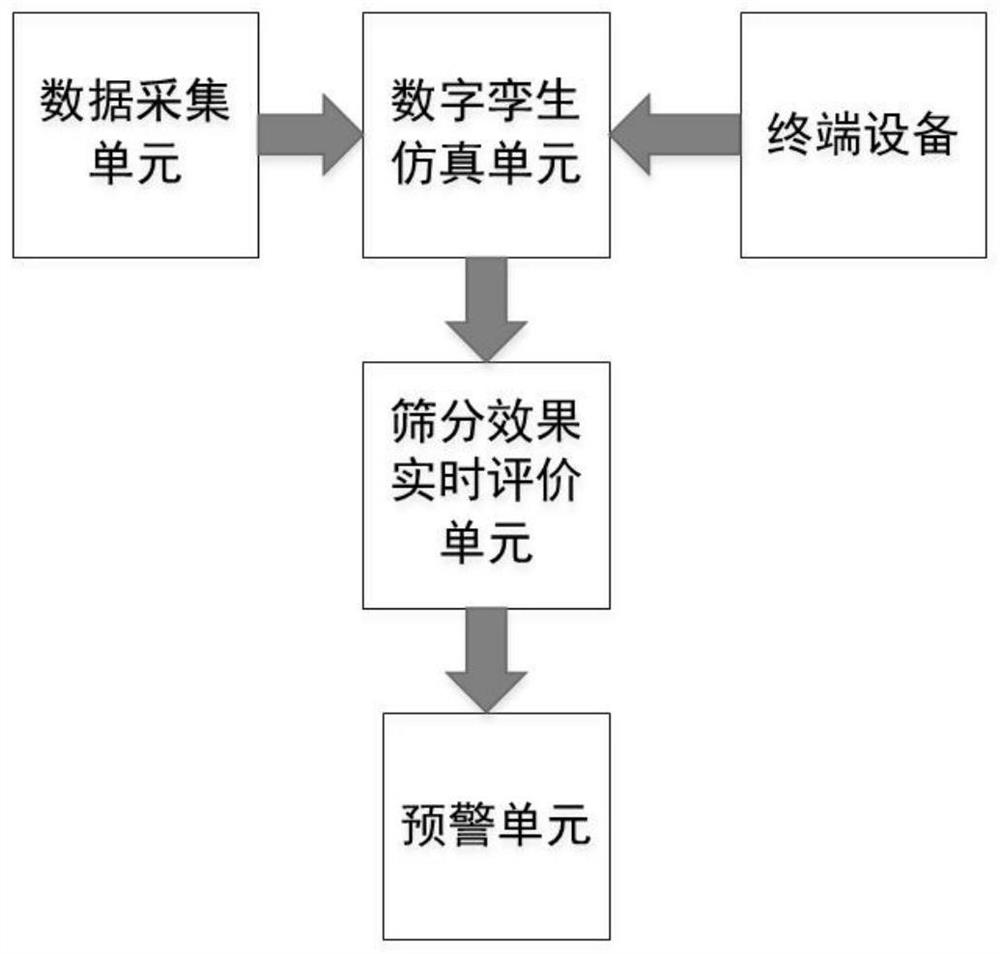

[0104] Taking a vibrating screen for coal 6mm screening as an example, when the vibrating screen in the model system runs stably, select any time to collect the working condition parameters and material parameters of the vibrating screen. details as follows:

[0105] For the operating parameters of the vibrating screen, (i) firstly 0 The stress and strain, acceleration, rotational speed and temperature at time and the acceleration information of the screen surface are collected.

[0106] (ii) will t 0 The stress-strain, acceleration, speed and temperature, and the acceleration information of the screen surface corresponding to the time are collected. The current stress-strain, acceleration, speed and temperature of the screen machine, and the acceleration information of the screen surface are compared with the data interval of the previously established cloud database to determine whether out of range ±5%.

[0107] (iii) If it exceeds the range of ±5%, it means that there m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com