A visual experimental device and working method for realizing polymer driving layer and layer injection

An experimental device and polymer technology, which is applied in the direction of earth drilling, mining fluid, measurement, etc., can solve the problems that there is no working method of polymer layered injection simulation experiment device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

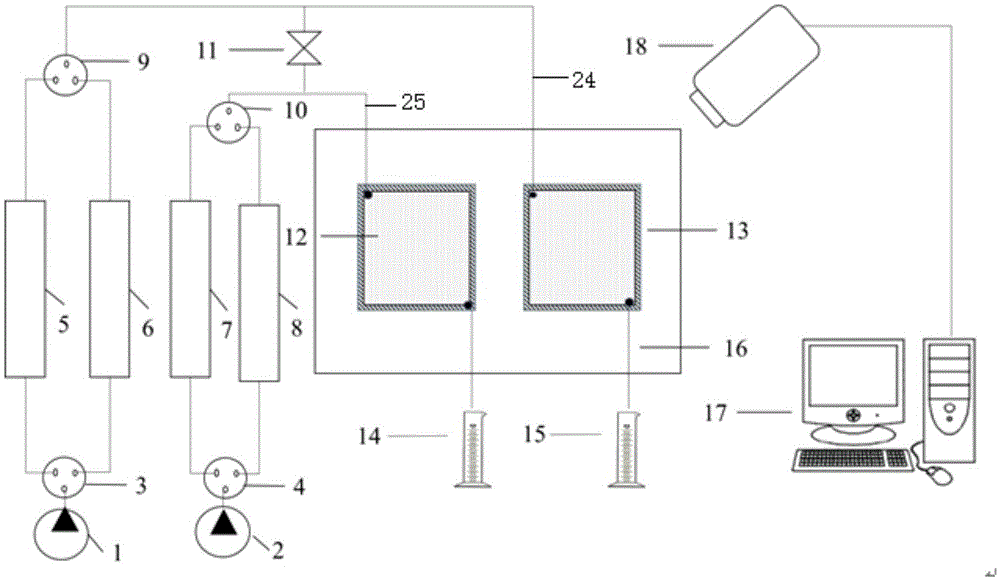

[0058] A visual experimental device for realizing polymer flooding and stratified injection, including a fluid injection and control system, a polymer seepage simulation system and an output fluid metering system, the fluid injection and control system, the polymer seepage simulation The system and the output fluid metering system are sequentially connected;

[0059] The polymer seepage simulation system includes a low-permeability flat sand filling model 12 and a high permeability flat sand filling model 13;

[0060] The fluid injection and control system includes a device that can control liquid layering or layering injection, and the liquid is any one of formation water, crude oil, polymer, and distilled water; the layering or layering in the fluid injection and control system The liquid flowing out in layers flows into the polymer seepage simulation system; the layering refers to that the liquid from the same liquid source is injected into the low-permeability flat sand-fi...

Embodiment 2

[0074] The working method of the experimental device described in embodiment 1, the concrete steps include:

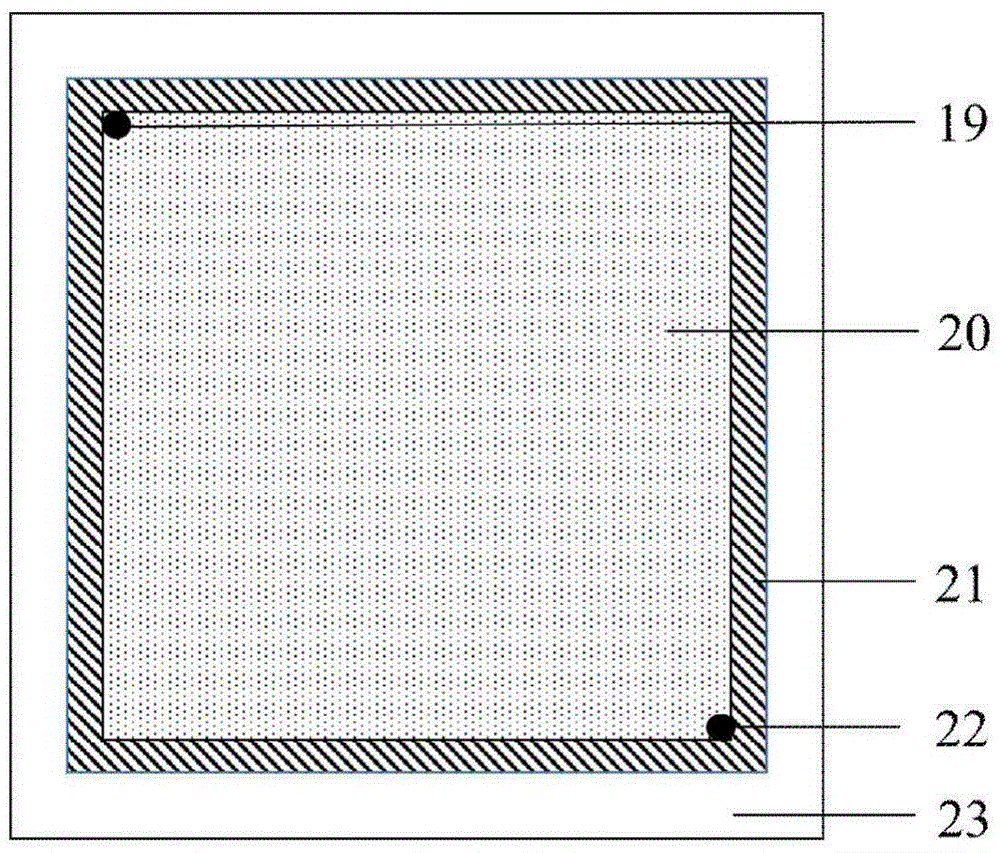

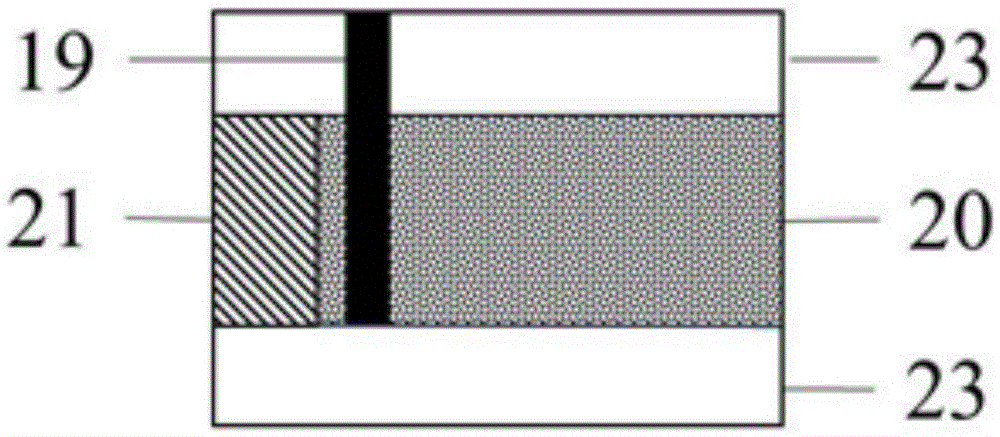

[0075] (1) Simulate the geological conditions of the reservoir: fill the low-permeability flat sand filling model 12 with 120 mesh quartz sand, fill the high permeability flat sand filling model 13 with 60 mesh quartz sand, and the filling thickness of the quartz sand is 0.5cm , wherein, the low-permeability flat sand-fill model 12 and the high-permeability flat sand-fill model 13 have the same size, both are 10cm in length, 10cm in width, and 0.5cm in height;

[0076] (2) Measure the porosity and permeability of the quartz sand in the low-permeability flat sand-filling model 12 and the high-permeability flat sand-filling model 13 respectively, and record: The porosity is φ 1 =0.30, the porosity of the quartz sand in the high-permeability flat sand filling model 13 is φ 2 =0.32, the permeability k of quartz sand in the low-permeability plate sand filling model 12 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com