Electric connector with shock absorption and transient interruption prevention structure and installation method

An electric connector and instantaneous disconnection technology, which is applied in the field of electrical connectors and installations with a shock-absorbing and anti-instantaneous disconnection structure, can solve problems such as systematic loss of control, excessive force, and hidden dangers of connector connection stability, and achieve strong The effect of anti-external force and anti-vibration, uniform feeding and conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

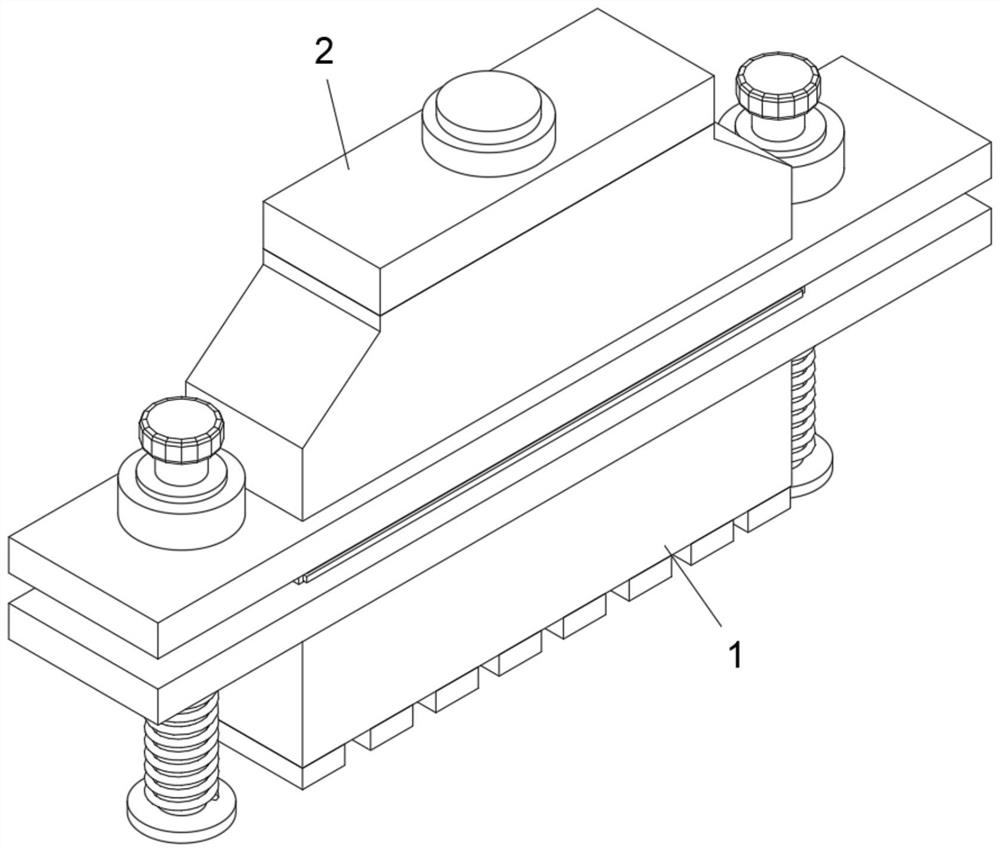

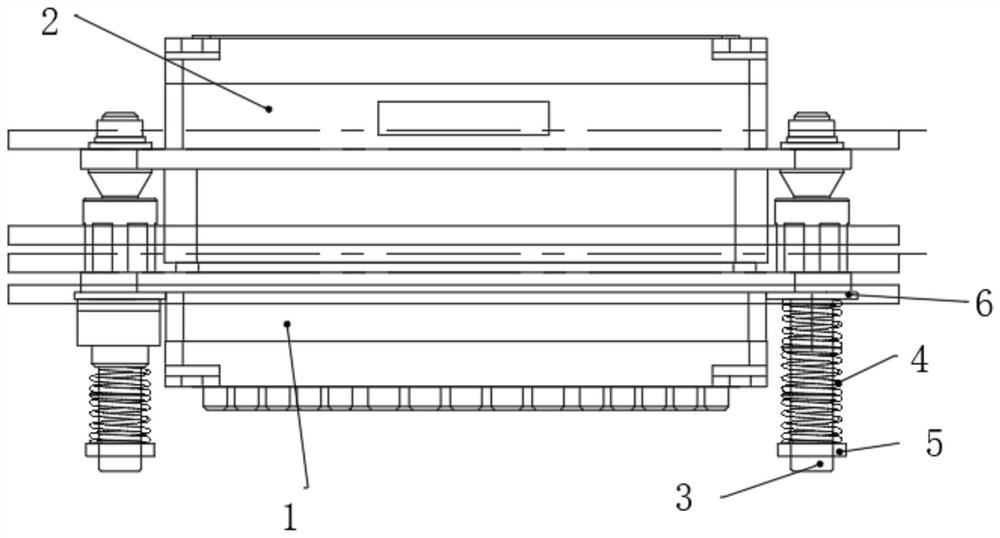

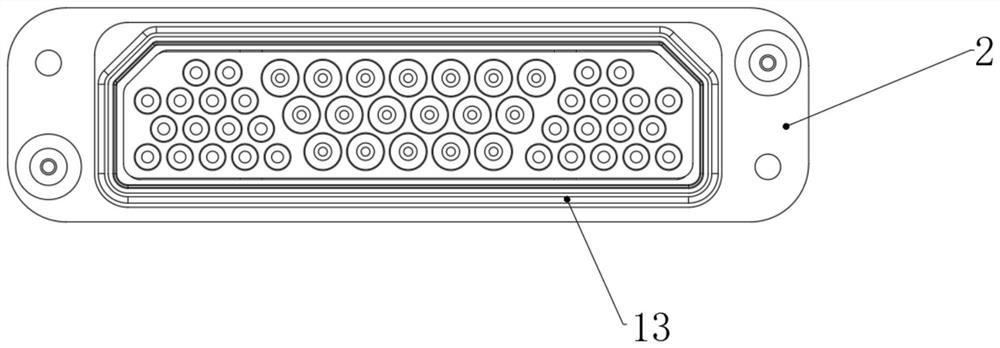

[0059] see figure 1 , figure 2 and Image 6 , an embodiment provided by the present invention: an electrical connector with a shock-absorbing and anti-instant breaking structure and an installation method, including a plug 1 and a socket 2, the plug 1 is plugged and fixed on the socket 2, and the external two parts of the plug 1 and the socket 2 are A dust cover 13 is fixedly installed on both sides;

[0060] see Figure 4 , the front ends of both sides of the socket 2 are fixedly installed with guide pins 9, and the inner sides of both sides of the socket 2 are threadedly installed with stainless steel hexagonal thin nuts 12. The flat washer 10 and the first stainless steel spring washer 11, the upper end of the socket 2 is fixedly installed with the first pan head screw 7 and the spring washer 8, and the first pan head screw 7 is fixedly inserted on the spring washer 8;

[0061] see Figure 5 , the inner two sides of the socket 2 are respectively fixed with a first sea...

Embodiment 2

[0071] On the basis of Example 1, as Figure 11 and Figure 12 As shown, a U-shaped auxiliary clamping member 45 is fixedly installed between the two ends of the plug 1 and the socket 2, and the U-shaped auxiliary clamping member 45 includes an L-shaped clamping plate 46, a limit threaded post 47, a sliding clamping plate 48, Squeeze and fasten the threaded post 49 and the extruding plate 50 , the sliding clamping plate 48 is slidably clamped inside the L-shaped clamping plate 46 , the extruding plate 50 is fixedly connected to the outer end of the sliding clamping plate 48 , and the limiting threaded post 47 is The threads are inserted into both ends of the sliding card plate 48, and the bottom ends of the extrusion plate 50 and the L-shaped clamping plate 46 are both screwed and inserted into the extrusion and tightening threaded posts 49. The outside of the front end is fixedly wrapped with a rubber cover.

[0072] In the implementation of this embodiment, by screwing the...

Embodiment 3

[0083] like Figure 14 , Figure 15 and Figure 16 As shown, an electrical connector with a shock-absorbing and anti-instant-break structure and an installation method include a uniform feeding cylinder 53, a fixed plate 54 is fixedly installed on the outside of the uniform feeding cylinder 53, and an upper end of the uniform feeding cylinder 53 is fixedly installed. A feeding hopper 52 is fixedly installed, the bottom end of the uniform feeding cylinder 53 is provided with a discharge port 55, one end of the uniform feeding cylinder 53 is fixedly installed with a motor 51, and the front end of the motor 51 is fixedly connected with a drive. shaft 58, a uniform conveying plate 57 is fixedly installed on the driving shaft 58, and a feeding slot 56 is evenly opened on the uniform conveying plate 57. The uniform conveying plate 57 is located directly below the feeding hopper 52, and the The uniform conveying plate 57 is in close contact with the inner wall of the uniform feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com