Batching equipment for environment-friendly impervious concrete production

A technology of impermeable concrete and batching equipment, which is applied in the direction of clay preparation equipment, mixing operation control, and the use of liquid separation agents, etc. It can solve problems such as escape, large material volume, and poor environmental quality at the production site, and achieve good environmental quality. The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

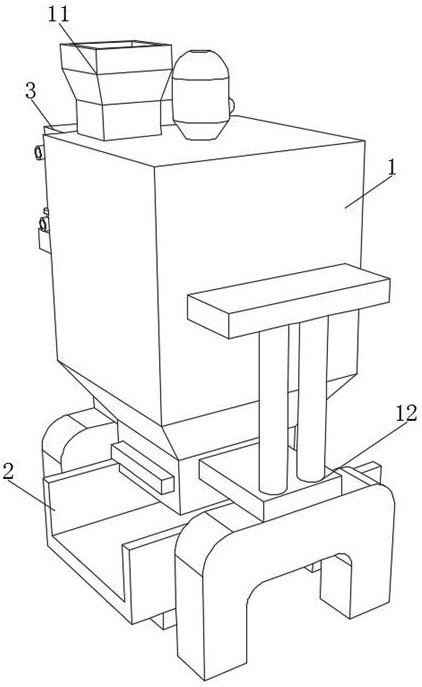

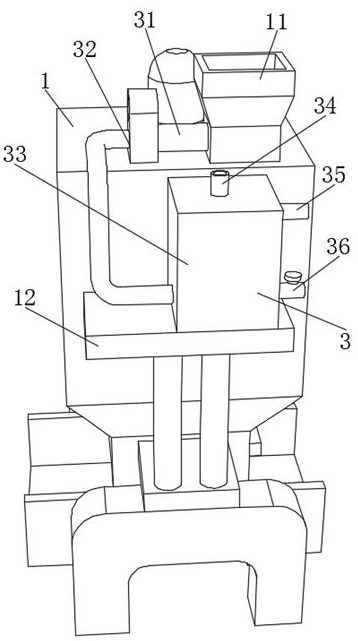

[0034] like Figure 1-6 As shown, the present invention provides a batching equipment for producing environmentally friendly impermeable concrete, comprising a batching equipment main body 1 and a transmission device 2, the transmission device 2 is arranged at the bottom of the batching equipment main body 1, and the upper surface of the batching equipment main body 1 is fixedly connected with a The feeding hopper 11, the outer side of the batching equipment main body 1 is fixedly connected with a support frame 12, the outer side of the batching equipment main body 1 is provided with a dust processing mechanism 3, the interior of the batching equipment main body 1 is provided with a crushing mechanism 4, and the dust processing mechanism 3 includes a Pipe 31, one end of the outlet pipe 31 is fixedly connected with the outer surface of the feeding hopper 11, one side of the outlet pipe 31 is provided with a water adsorption box 33, the crushing mechanism 4 includes a power devic...

Embodiment 2

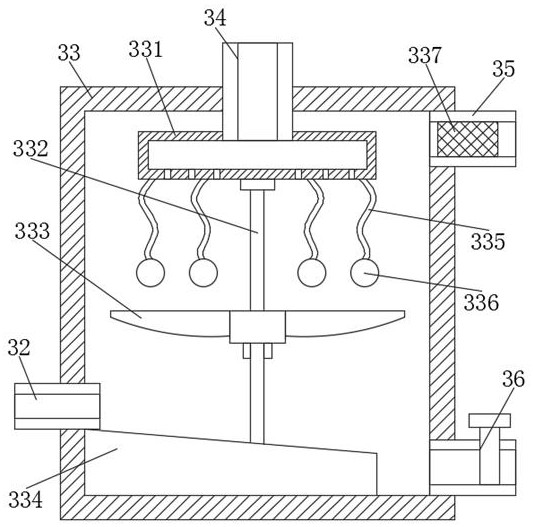

[0037] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, one end of the water inlet pipe 34 is fixedly connected with a spray device 331, and the lower surface of the spray device 331 is fixedly connected with a fixed rod 332 and a pull A rope 335, a light-weight rotating fan 333 is movably connected to the outer surface of the fixing rod 332, and a liquid guide block 334 is fixedly connected to one end of the fixed rod 332. One end of the rope 335 is fixedly connected with a lightweight auxiliary adsorption ball 336, the inner wall of the air outlet pipe 35 is fixedly connected with a filter drying plate 337, and the outer surface of the lightweight auxiliary adsorption ball 336 is fixedly connected with a guide pipe 3361, the guide pipe 3361 An expansion ball 3362 is set at one end of the expansion ball 3362 , and a deflector 3363 is fixedly connected to the outer surface of the expansion ball 3362 .

...

Embodiment 3

[0040] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a rotating rod 1 41 is movably connected to the inner wall of the main body 1 of the batching equipment, and the output shaft of the power device is fixed to one end of the rotating rod 1 41 Connection, the upper surface of the connecting plate 42 is movably connected with one end of the rotating rod 1 41, the motor 47 is fixedly connected on the outer surface of the rotating rod 1 41, and one end of the rotating rod 2 43 is movably connected with the lower surface of the connecting plate 42, the crushing component 44 is arranged on the outside of the second rotating rod 43, one end of the rotating assembly 48 is movably connected to the outer surface of the crushing assembly 44, the outer surface of the support plate 45 is fixedly connected to the inner wall of the batching equipment main body 1, and the filter screen 46 is connected to the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com