Five-degree-of-freedom 3D printer

A 3D printer, a degree of freedom technology, used in the improvement of process efficiency, manufacturing auxiliary devices, additive processing, etc., can solve the problems of wear and tear of 3D printers and desktops, inconvenient rotation of 3D printers, etc., to achieve quality assurance, prolong service life, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

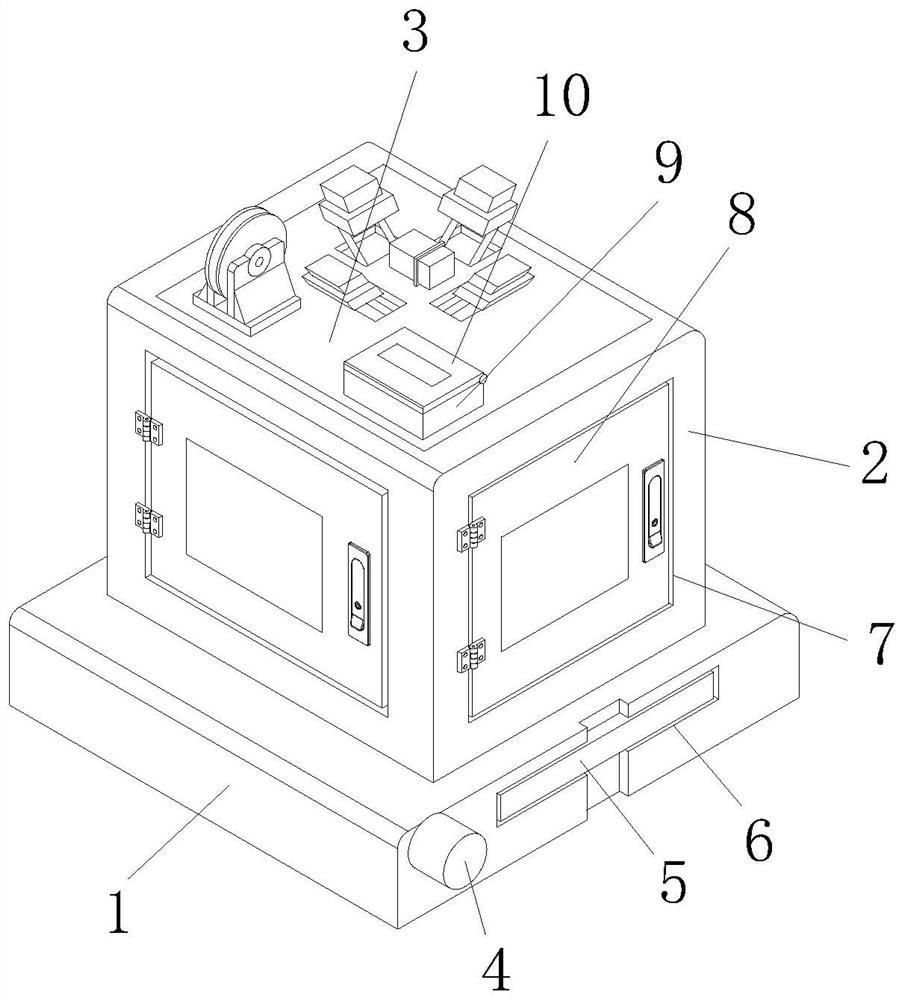

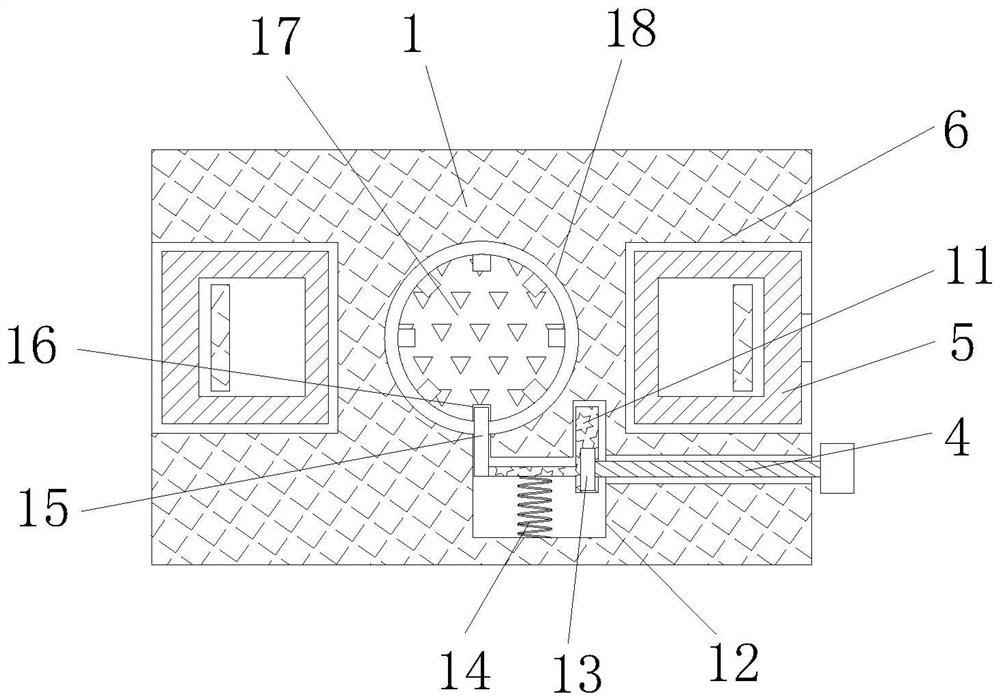

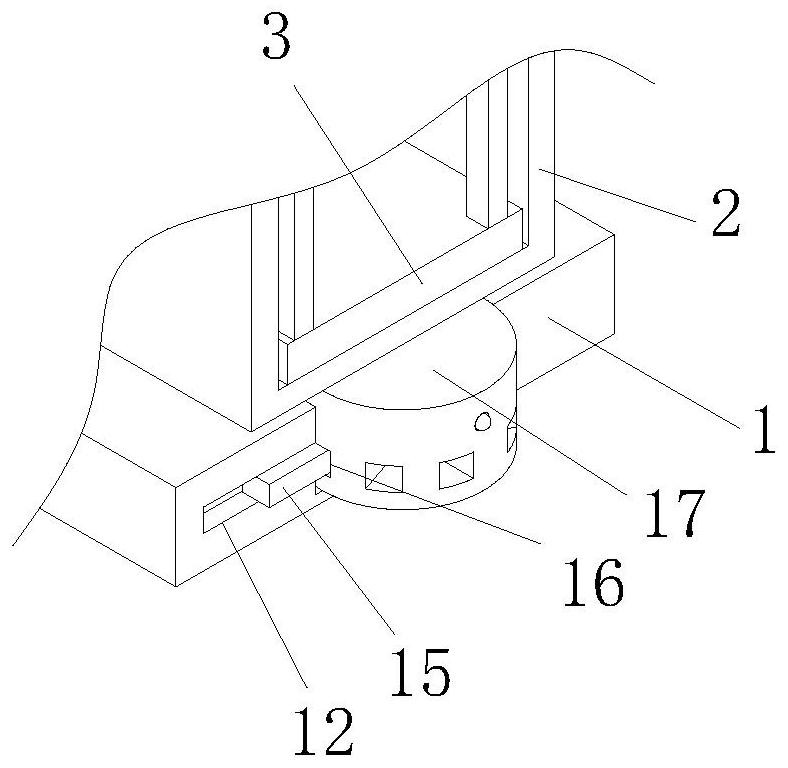

[0027] see Figure 1-3 , the present invention provides a technical solution: a 3D printer with five degrees of freedom, comprising a base 1, a protective box 2 is arranged on the top of the base 1, the inner wall of the protective box 2 is fixedly connected with a printer body 3, and the printer body 3 has five A printer with one degree of freedom, the printer body 3 is an existing structure, and I won’t go into details here. The printer body 3 can print materials. The top of the printer body 3 is provided with a display guard, and the top of the base 1 is provided with a rotation slot. 18. A rotating column 17 is rotatably connected to the inner wall of the rotating groove 18. The top of the rotating column 17 is fixedly connected to the bottom of the protective box 2. The protective box 2 and the printer body 3 can be rotated on the top of the base 1 through the rotating column 17. The base 1 There are bumps at the bottom of the base 1 to increase the friction force of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com