Automatic loading and sealing all-in-one machine

An automatic charging and integrated machine technology, applied in the field of automatic sealing device, automatic charging and sealing integrated machine, can solve the problems of low efficiency, a lot of labor, waste and other problems, achieve high-speed and high-efficiency production, save labor, reduce glue opening The effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

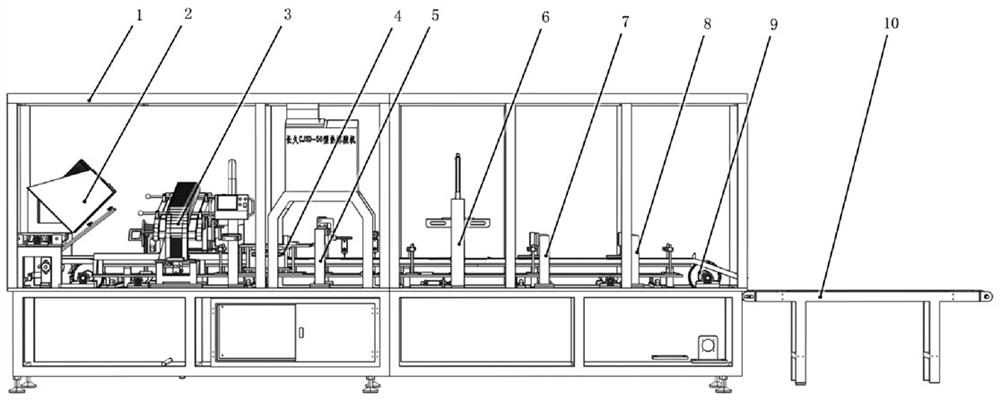

[0052] The all-in-one machine of the present application is used to automatically fold and seal the jammed paper. Figure 13 Figure 14 As shown, there are three bending lines on the cardboard, namely the push-up line A2-1, the side push line A2-2 and the push-up bending line A2-5. There are also two gluing areas on the cardboard, respectively For the horizontal glue line A2-3 and the vertical glue line A2-4, there are two longitudinal glue lines, located at the waist position on both sides of the cardboard, one horizontal glue line, vertical and longitudinal glue lines and in the longitudinal direction The position other than the end of the glue line and the position between the waists on both sides of the cardboard is the card holder A1 placement area.

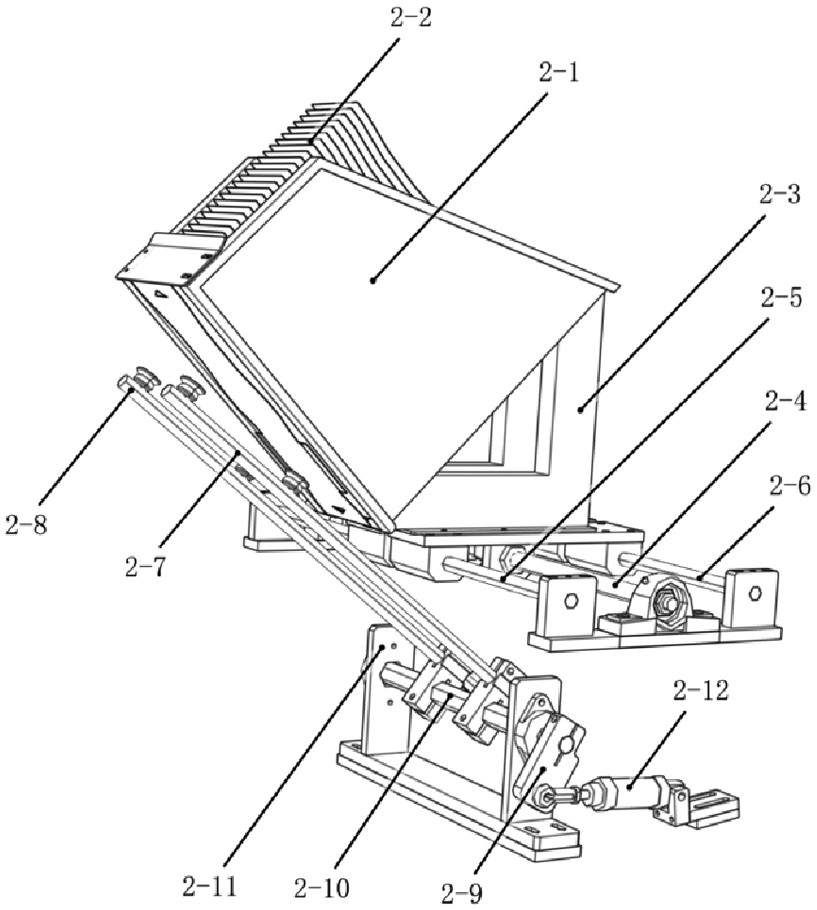

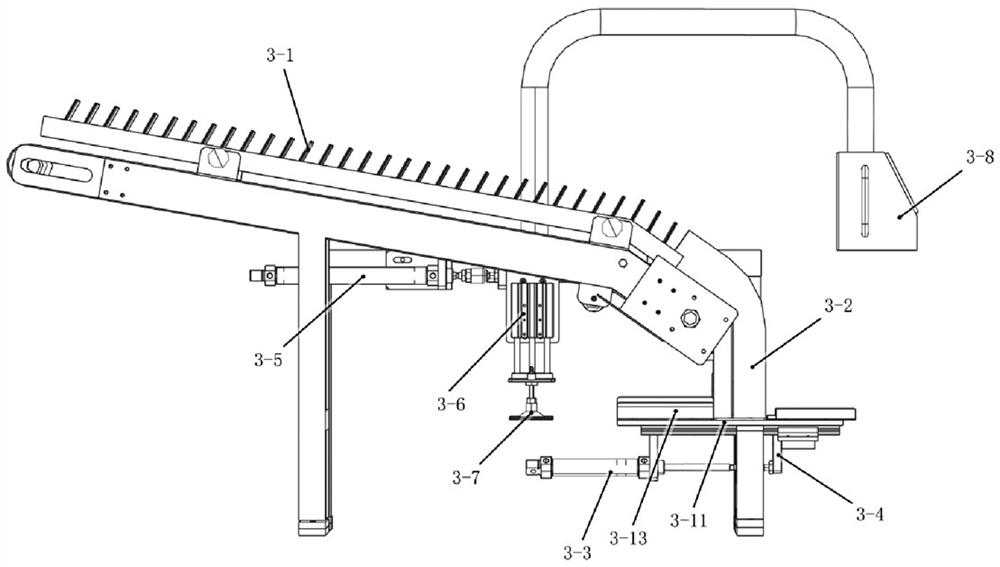

[0053] The all-in-one machine is described in detail below, such as figure 1 As shown, an automatic charging and sealing integrated machine, comprising:

[0054] rack 1;

[0055] The transmission unit 9 is arranged on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap