Full-automatic liftable cement loading and unloading device

A loading and unloading device and fully automatic technology, which is applied in loading/unloading, conveyor control devices, transportation and packaging, etc., can solve the problems of high labor costs, large cement dust, and low handling efficiency, so as to reduce labor costs and improve loading and unloading Efficiency, neatly stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

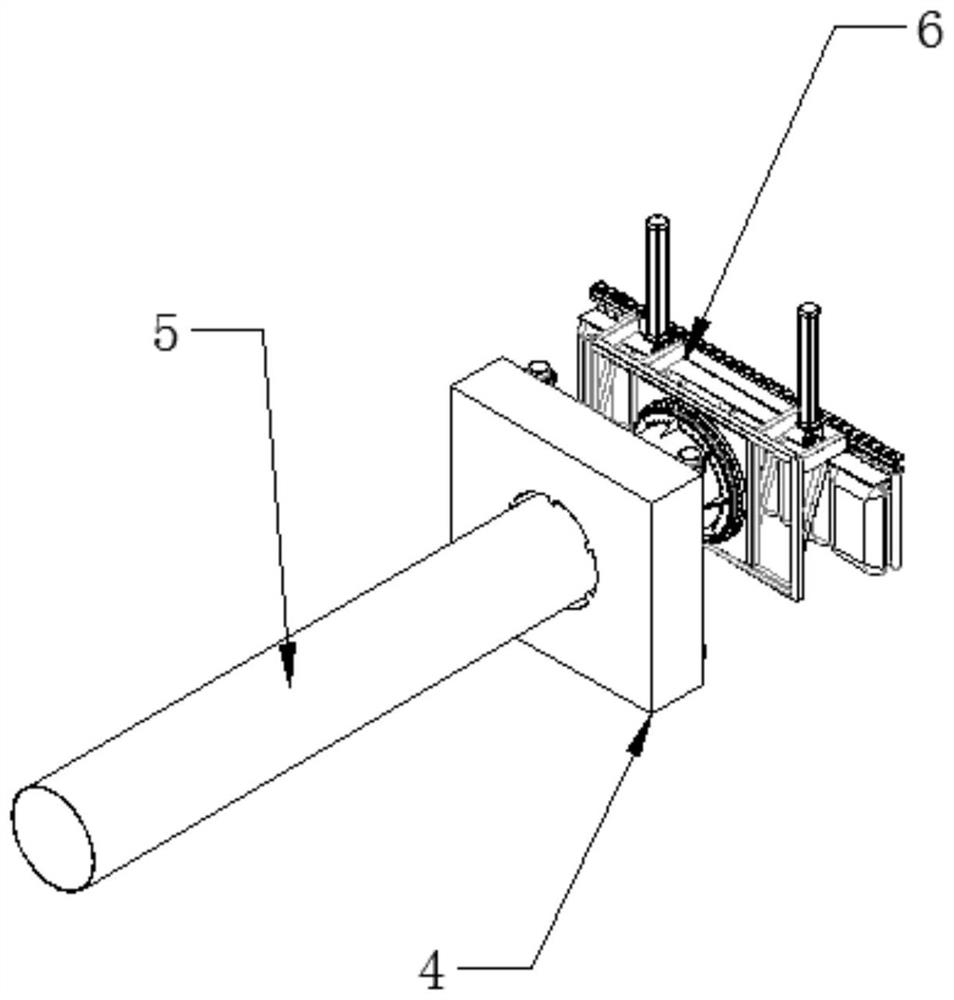

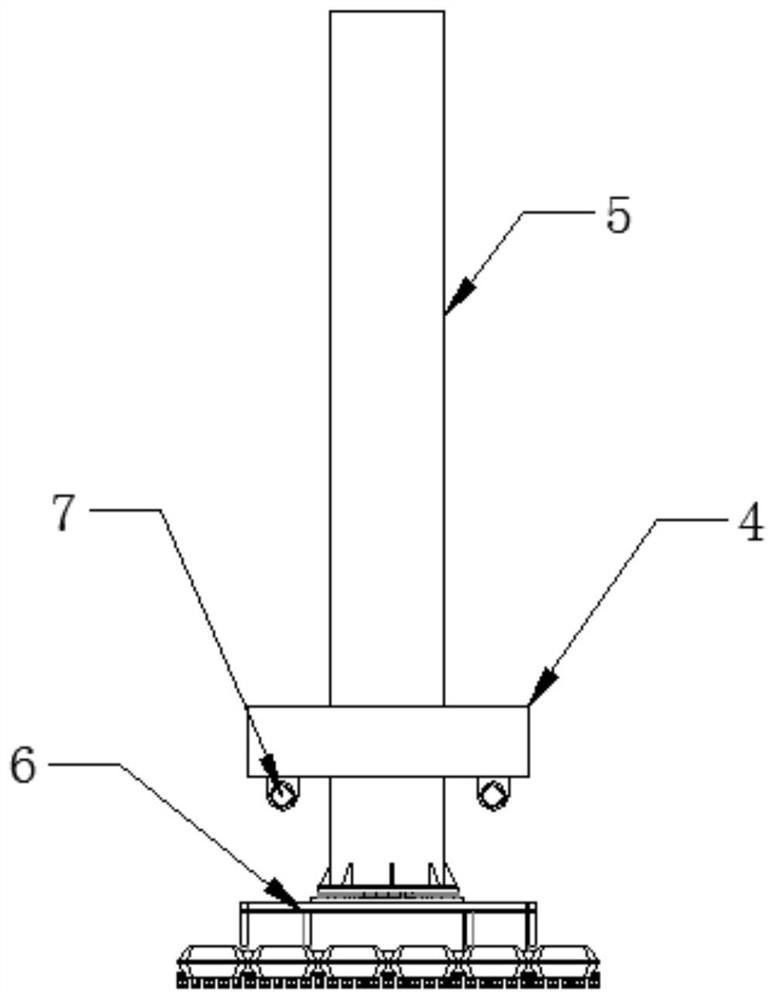

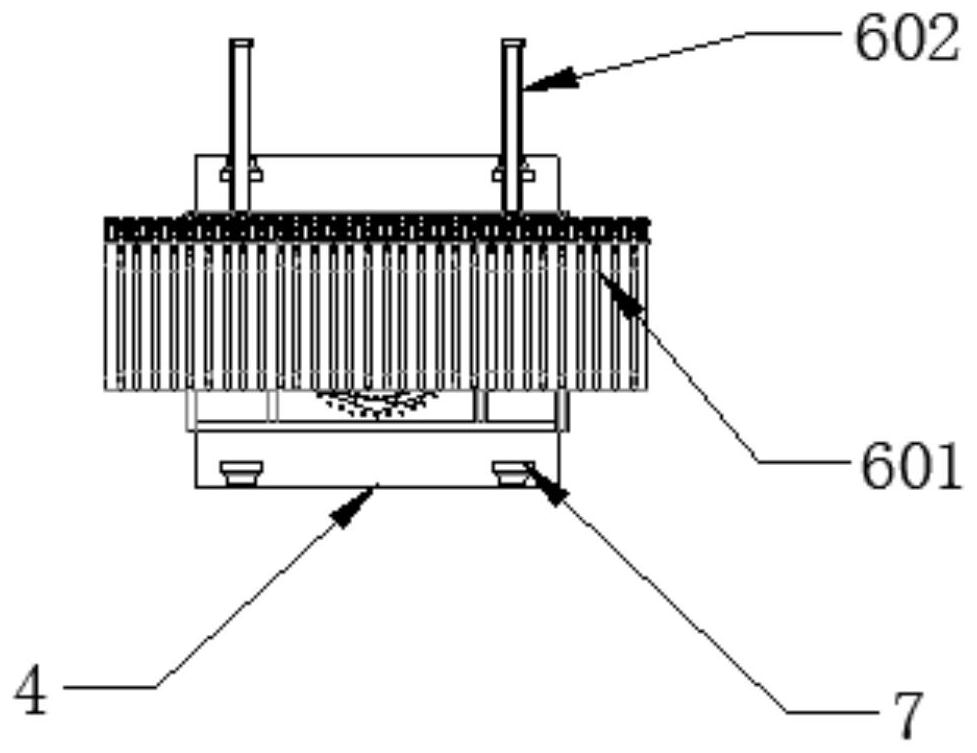

[0024] see Figure 1 to Figure 8 As shown, the present invention adopts the following technical scheme: a fully automatic liftable cement loading and unloading device, comprising a mobile platform 4, a lifting column 5 that can be lifted up and down in the mobile platform 4, and a loading and unloading frame 6 arranged at the bottom of the lifting column 5 , the bottom four corners of the mobile platform 4 are provided with rollers 7, the bottom end of the lifting column 5 is provided with a rotating chain 501, and a triangular fixing plate 502 vertically arranged with the lifting column 5 and the rotating chain 501 respectively, the loading and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap