Refrigeration compressor shell, refrigeration compressor and refrigeration system

A technology for refrigeration compressors and refrigeration systems, applied in refrigerators, compressors, refrigeration components, etc., can solve problems such as complex structures and increased costs, and achieve the effects of reducing volume, avoiding liquid shock, and being simple and complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

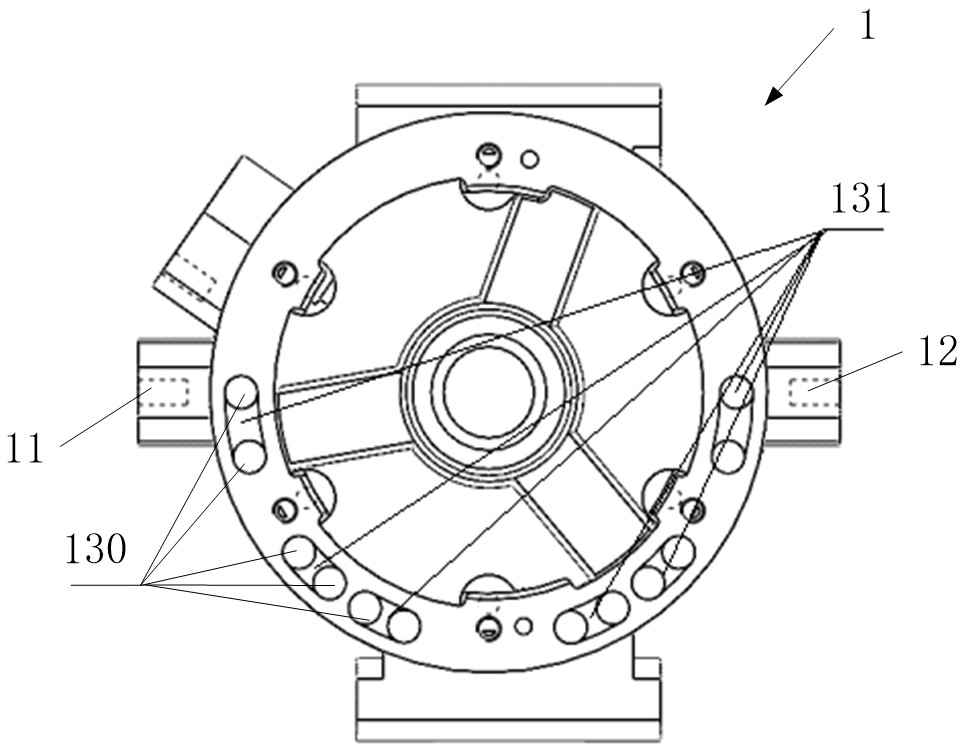

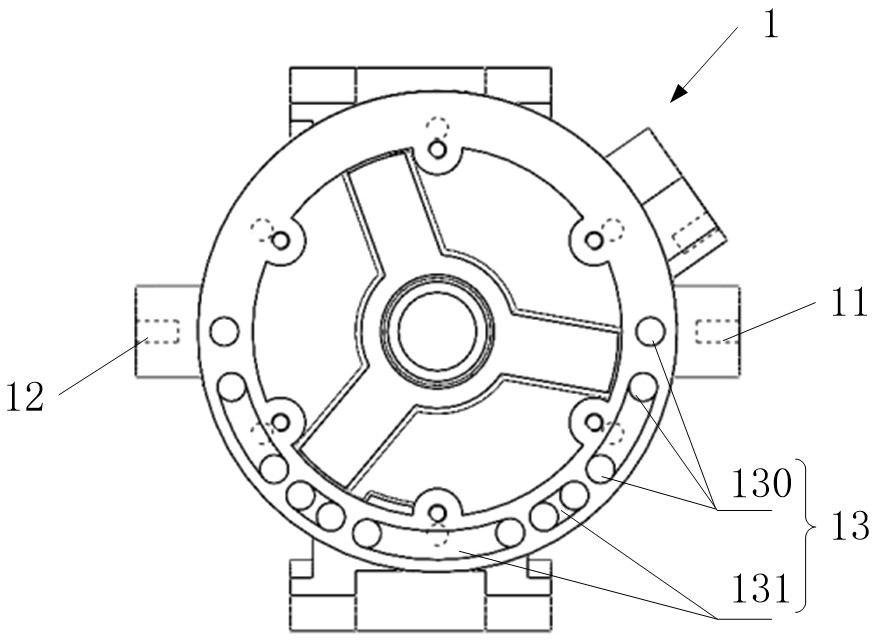

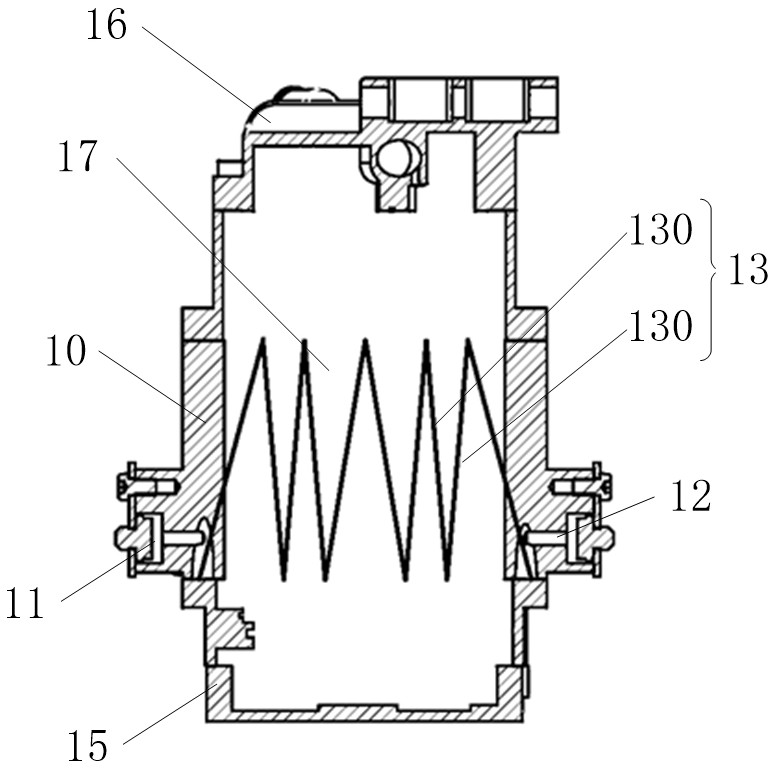

[0066] see Figure 1 to Figure 10 As shown, the first embodiment of the present application provides a refrigeration compressor casing 1, the refrigeration compressor casing 1 includes a casing body 10 surrounding a compression cavity 17 (for example, see image 3 ), the compression cavity 17 is used for the passage of the refrigerant medium, and the refrigerant medium is compressed and pressurized in the compression cavity 17 .

[0067] The casing body 10 has a specified length direction and a circumferential direction. Here, the length direction of the casing body 10 is defined as the direction in which the refrigerant enters and exits with respect to the compression cavity 17 , and the circumferential direction of the casing body 10 is defined as a direction perpendicular to the casing. The section in the longitudinal direction of the body body 10 faces the direction defined by the outer peripheral edge of the cross section obtained by cutting the casing body 10 . For exam...

Embodiment approach

[0147] In the optional solution of this embodiment, the boundary line delimiting all the heat exchange channels 13 is defined as the heat exchange area. Regarding the size of the heat exchange area, the heat exchange area covers part or all of the circumferential direction of the housing body 10, Regarding another embodiment in which the size of the heat exchange area is set, the heat exchange area extends over part or all of the longitudinal direction of the casing body 10 .

[0148] That is, the heat exchange area may extend over the entire circumference of the case body 10 and over the entire length of the case body 10 , or the heat exchange area may cover the entire circumference of the case body 10 and over the case body 10 in the lengthwise direction, or the heat exchange area may extend over a circumferential portion of the casing body 10 and over the entire lengthwise direction of the casing body 10, or the heat exchange area may extend over a circumferential portion of...

Embodiment 2

[0161] Embodiment 2 provides a refrigeration compressor. This embodiment includes the refrigeration compressor casing in Embodiment 1. The technical features of the refrigeration compressor casing disclosed in Embodiment 1 are also applicable to this embodiment. Embodiment 1 The technical features of the disclosed refrigeration compressor housing will not be described repeatedly.

[0162] combine Figure 1 to Figure 9 and see Figure 10 As shown, the refrigeration compressor 2 provided in this embodiment includes a refrigeration compressor casing 1, so that the working parts in the refrigeration compression chamber of the refrigeration compressor 2 are supported and protected by the refrigeration compressor casing 1, and the working parts in the refrigeration compression chamber of the refrigeration compressor 2 are supported and protected by the refrigeration compressor casing 1. The casing 1 provides an access point for the refrigeration compressor 2 to be connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com