Medium-sized excavator electric control multi-way valve

A multi-way valve, electromechanical technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, mechanical equipment, etc. Control problems such as poor flexibility to achieve the effects of reducing pressure loss, good compound action control performance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

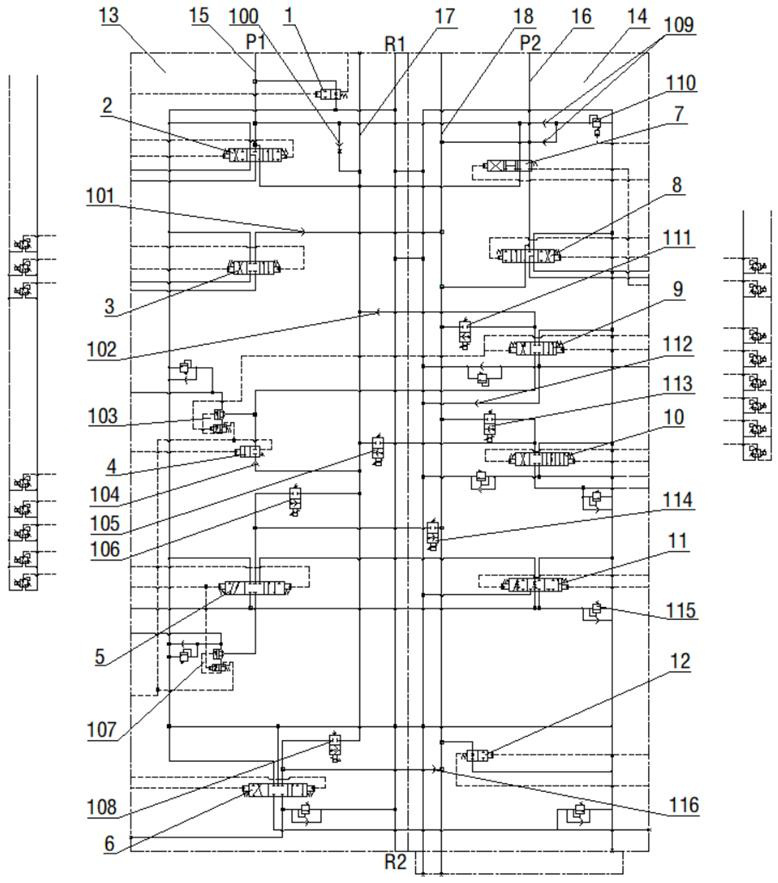

[0019] Example 1, refer to figure 1 shown:

[0020] [Please combine with the attached figure 1 The name of each component and the connection relationship explain the function, action process and beneficial effect of each component]

Embodiment 2

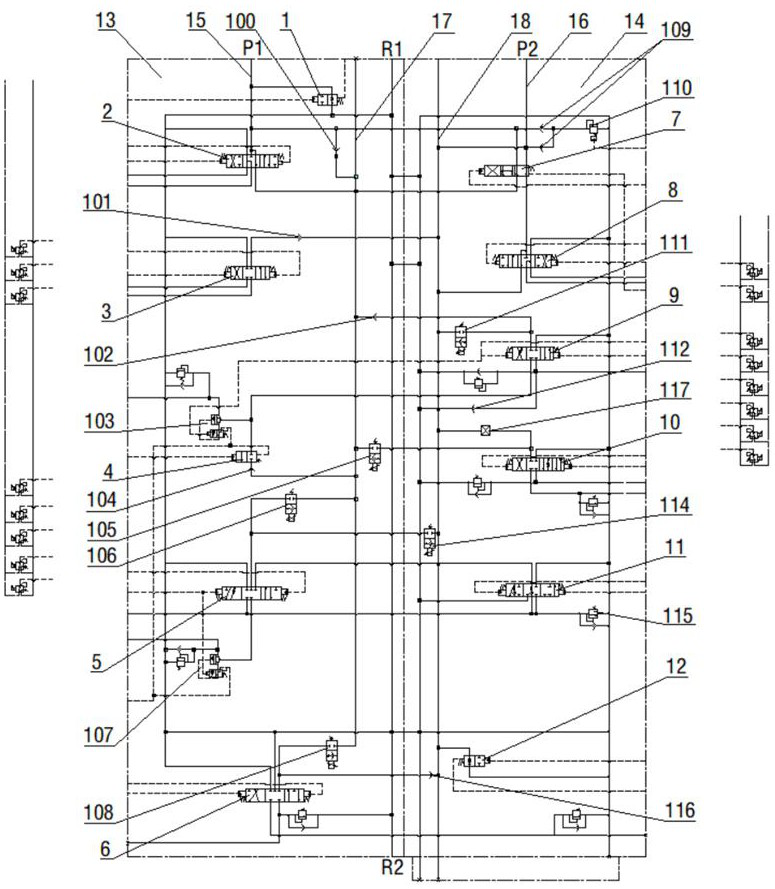

[0021] Example 2, refer to figure 2 shown:

[0022] [Please combine with the attached figure 1 The name of each component and the connection relationship explain the function, action process and beneficial effect of each component]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com