Rigidity judgment method of light assembly type composite floor slab and computer readable storage medium

A technology of combined floor and determination method, applied in sustainable transportation, design optimization/simulation, instruments, etc., can solve the problems affecting the promotion and application of lightweight prefabricated composite floor, the difficulty of composite floor stiffness analysis, and is not suitable for general engineering and technical personnel. and other problems, to achieve the effect of simple stiffness determination method, simple deflection calculation formula and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

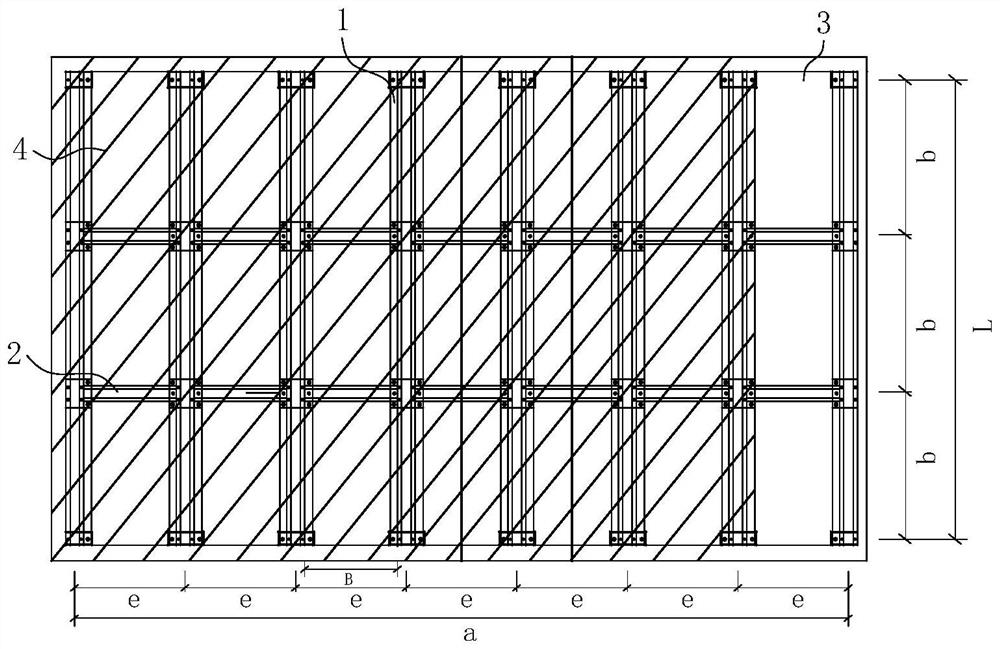

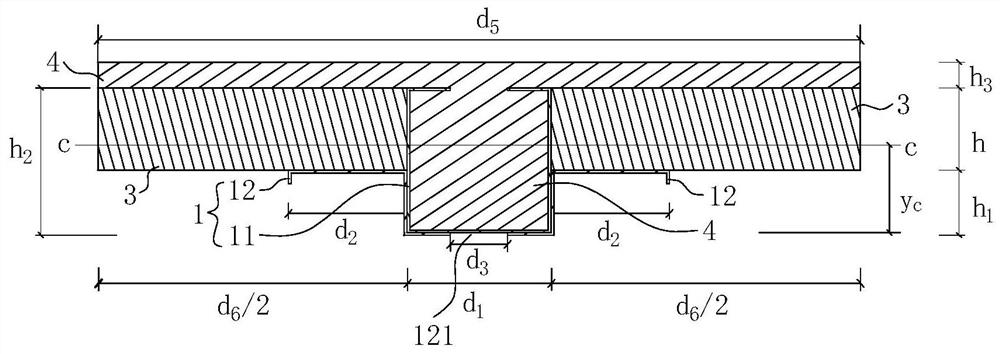

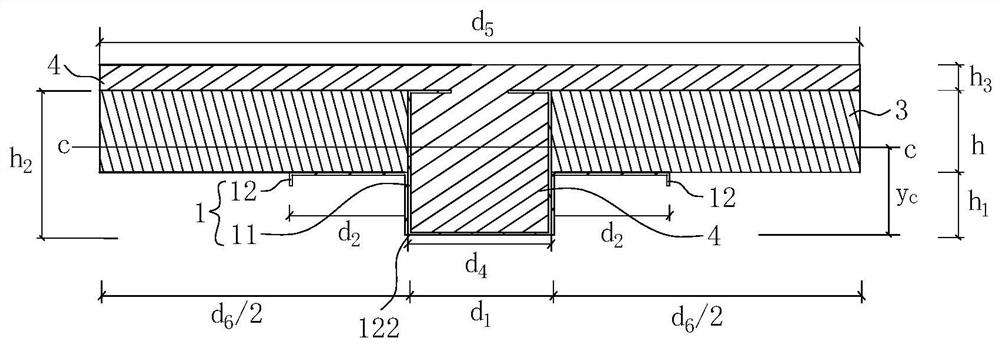

[0083] There is an existing four-side simply supported composite floor, where B=500mm, a=3600mm, L=2500mm, and the uniform load q=4kN / m 2 . A beam element with a width e=600mm and a length L=2500mm is cut from the four-side simply supported composite floor. The section of the beam element along the e direction is as follows: Figure 2-4 shown. The elastic modulus of the thin-walled main beam 11 and the thin-walled auxiliary beam 12 are both E s =2×10 8 kN / m 2 , the wall thickness is t=1mm. The post-cast layer 4 is cement mortar, and the elastic modulus is E c =2.17×10 7 kN / m 2 .

[0084] Let h = 40mm, 45mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm, 80mm, respectively. Refer to Table 2 to interpolate the correlation coefficient ρ to calculate ρ = 0.46, and calculate respectively according to the deflection calculation formula (10). Figure 2-4 The maximum vertical displacement Δ of the three types of composite floor slabs under known uniform loads 1 ,Δ 2 ,Δ 3 , and obtain...

Embodiment 2

[0090] There is a four-sided simply supported composite floor, where B=600mm, a=3500mm, L=3000mm, and the uniform load q=4kN / m 2 . A beam element with a width e=700mm and a length L=3000mm is taken from the four-side simply supported composite floor. The section of the beam element along the e direction is as follows: Figure 2-4 shown. The elastic modulus of the thin-walled main beam 11 and the thin-walled auxiliary beam 12 are both E s =2×10 8 kN / m 2 , the thickness of the prefabricated board 3 is h=40mm. The post-cast layer 4 is cement mortar, and the elastic modulus is E c =2.17×10 7 kN / m 2 .

[0091] Let t=0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm, 1.8mm, 2.0mm, 2.2mm, respectively, and refer to Table 3 to interpolate the correlation coefficient ρ to calculate the correlation coefficient ρ=0.36, according to the deflection The calculation formula (10) is calculated separately Figure 2-4 The maximum vertical displacement Δ of the three types of composite floor sl...

Embodiment 3

[0096] There is a four-sided simply supported composite floor, where B=600mm, a=4900mm, L=5000mm, and the uniform load q=4kN / m 2 . A beam element with a width e=700mm and a length L=5000mm is taken from the four-sided simply supported composite floor. The section of the beam element along the e direction is as follows: Figure 2-4 shown. The elastic modulus of the thin-walled main beam 11 and the thin-walled auxiliary beam 12 are both E s =2×10 8 kN / m 2 , the thickness of the prefabricated board 3 is h=40mm. The post-cast layer 4 is cement mortar, and the elastic modulus is E c =2.17×10 7 kN / m 2 .

[0097] Let t=0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm, 1.8mm, 2.0mm, 2.2mm, respectively, refer to Table 3 to interpolate the correlation coefficient ρ to calculate the correlation coefficient ρ=0.26, according to the deflection The calculation formula (10) is calculated separately Figure 2-4 The maximum vertical displacement Δ of the three types of composite floor slabs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com