Guiding rail assembly and cable dragging device of coal mining machine

A guide rail and guide rail technology, which is applied in the installation of cables, cable arrangement between relatively moving parts, electrical components, etc., can solve the problem of increased production costs and maintenance costs, high processing accuracy requirements, inconvenient installation and maintenance, etc. problems, to achieve the effect of reducing processing costs, low assembly difficulty, and easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

[0031] The guide rail assemblies provided according to some embodiments of the present invention will be described below with reference to the accompanying drawings.

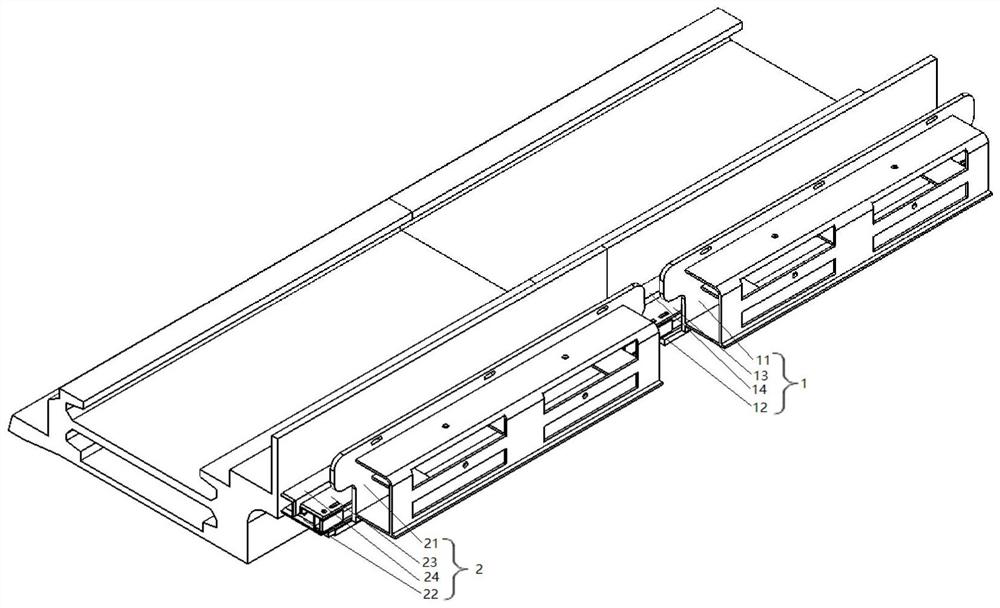

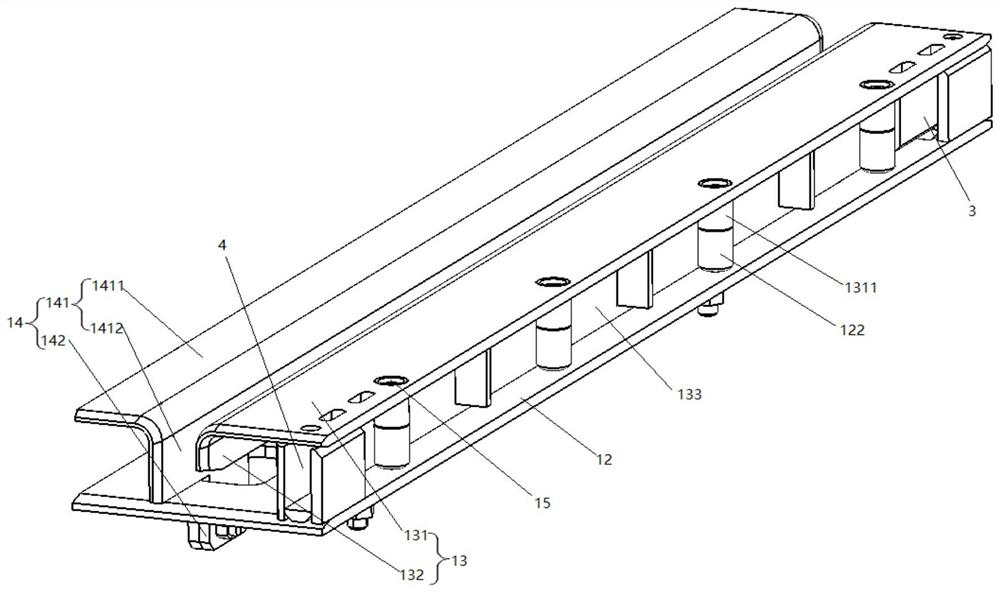

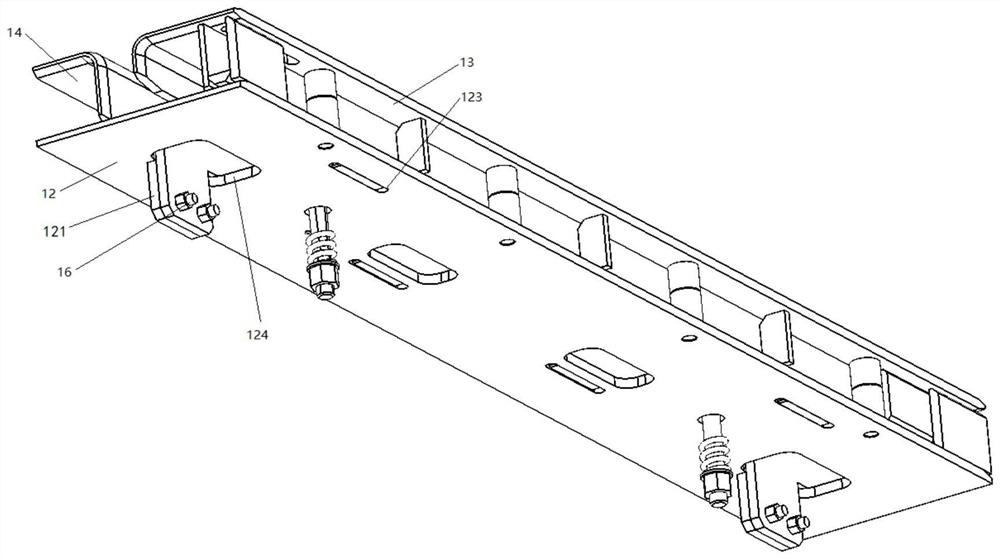

[0032] like Figure 1-Figure 6 As shown, the guide rail assembly according to the embodiment of the present invention comprises a plurality of drag rails connected in sequence, the drag rails include a first drag rail 1 and a second drag rail 2, and two adjacent segments of the first drag rail At least one second drag track 2 is included between 1 .

[0033] It can be understood that the guide rail is composed of multiple first drag rails 1 and multiple second dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com