Device and method for hoisting equipment in limited space

A technology of limited space and lifting device, applied in the direction of lifting equipment braking device, hoisting device, transportation and packaging, etc., can solve the problems of floor or cabin damage, personal injury, increase work intensity, etc., to reduce labor Strength, damage avoidance, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

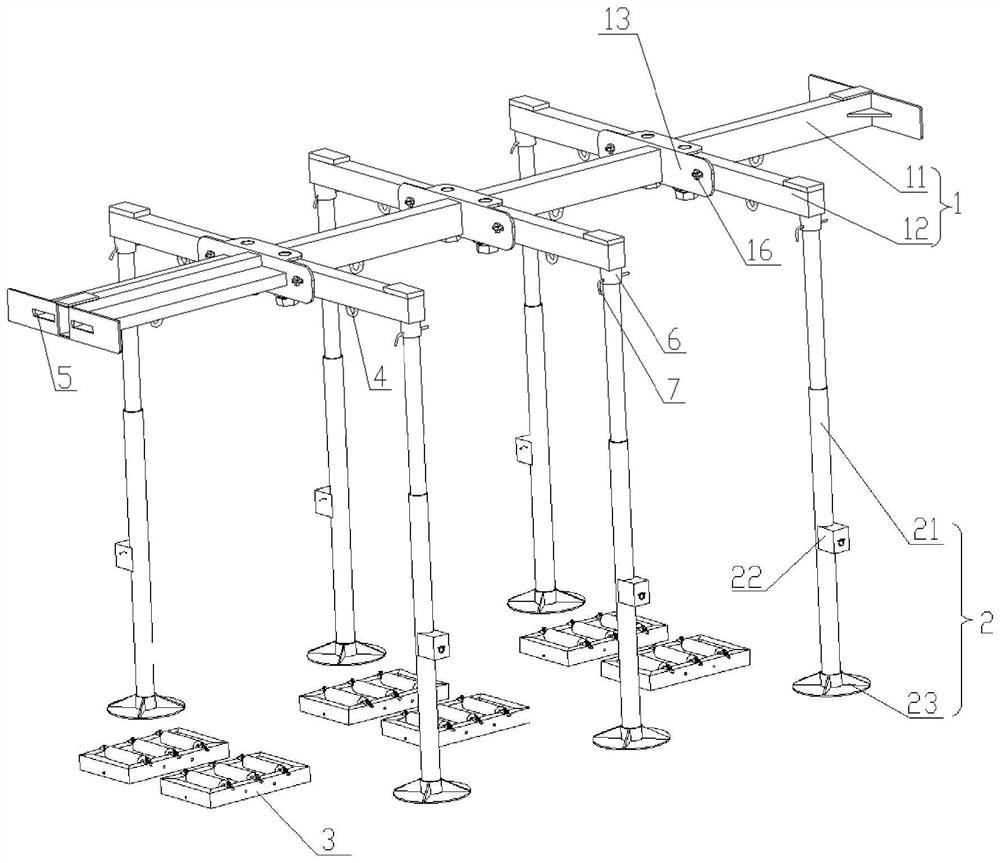

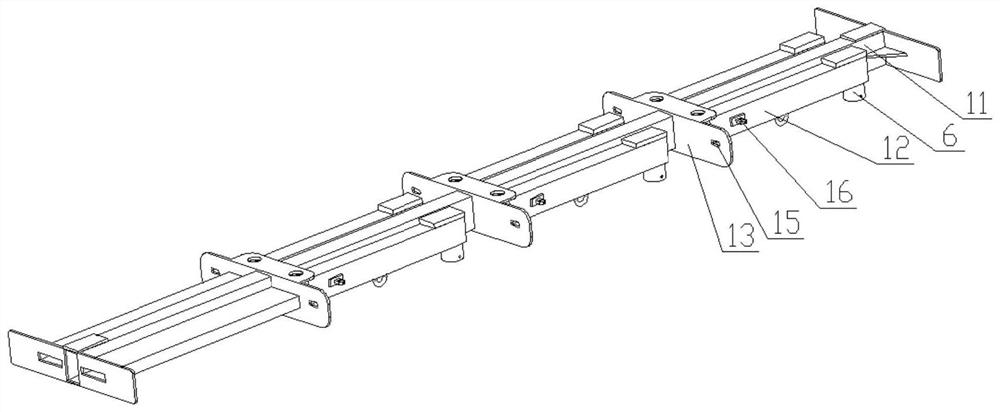

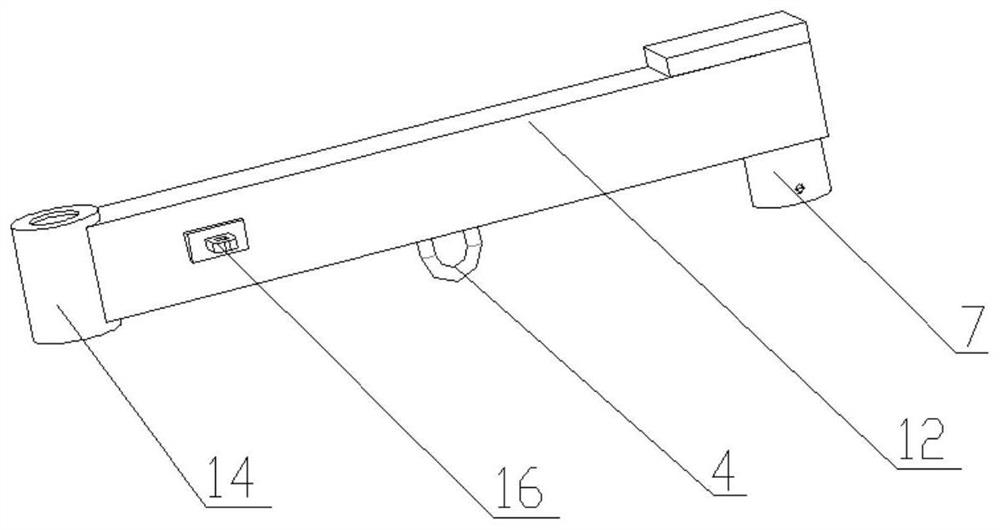

[0033] The device and method for lifting equipment in a confined space provided by the present invention will be explained and described in detail below with reference to the accompanying drawings.

[0034] This embodiment specifically discloses a device hoisting device in a confined space, such as figure 1 As shown, it includes a folding suspension 1 , a lifting leg 2 and a sliding assembly 3 . The lifting leg 2 is supported below the folding suspension 1 , and the height of the folding suspension 1 is adjusted by the lifting and lowering of the lifting leg 2 . The folding suspension 1 includes a main beam 11 and multiple groups of cantilevers. The multiple groups of cantilevers are distributed along the length of the main beam 11 , and the adjacent two groups of cantilevers are separated by a certain distance. Cantilever 12, one end of the cantilever 12 is rotatably connected to the main beam 11, and the other end of the cantilever 12 is detachably connected to the lifting l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com