Hub bearing structure

A wheel hub bearing and bearing technology, which is applied in the direction of the wheel hub, shaft, bearings, bearing components, etc., can solve the problems of large friction loss, reduce torque, and load capacity is not as strong as that of cylindrical roller bearings, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

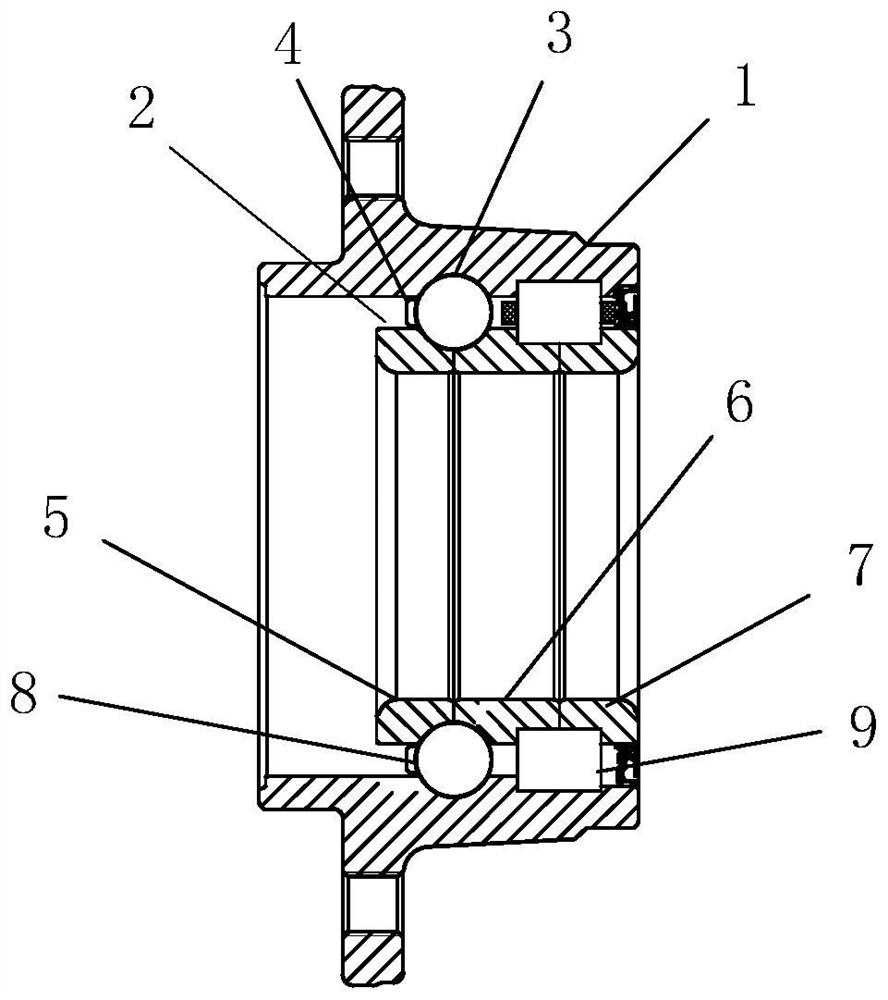

[0016] Examples of the wheel hub bearing structure of the present invention are: figure 1 Shown: the rolling elements 3 are separated by the cage 4, the inner ring 2 is provided with the left bearing ring 5 and the middle bearing ring 6 of the bearing and the right bearing ring 7, and the left bearing ring 5 and the middle bearing ring 6 of the bearing are combined to form a The ball 8 is in contact with the channel, the middle bearing ring 6 and the right bearing ring 7 are combined to form a raceway in contact with the cylindrical roller 9, the rolling body 3 is provided with a steel ball 8 and a cylindrical roller 9, and the cylindrical roller 9 is arranged inside Between the raceway on the ring 2 and the raceway on the flange outer ring 1, the cylindrical roller 9 is in line contact with the inner ring 2 and the flange outer ring 1, and the contact between the outer steel ball 8 of the bearing and the channel, The contact angle is 35 degrees, and the flange outer ring 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com