Bidirectional hydraulic damping device

A damping device, two-way hydraulic technology, applied in the field of machinery, can solve the problems of unstable damping force, unobstructed oil circuit and high cost, and achieve the effects of effective buffering, simple and reliable device structure and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar mechanisms and similar changes of the present invention should be included in the protection scope of the present invention.

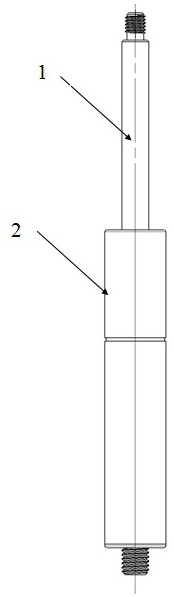

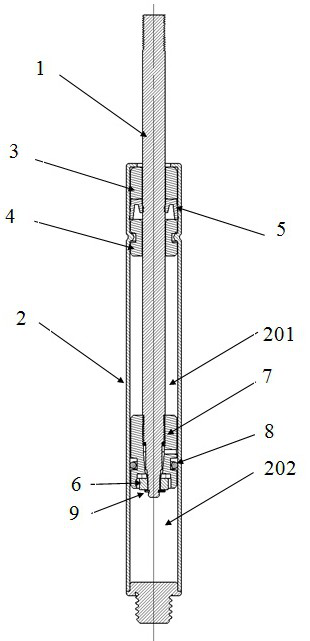

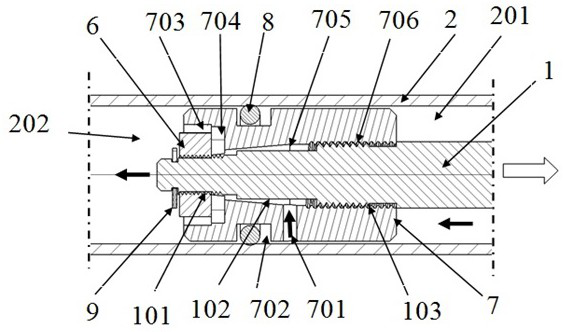

[0018] like Figure 1 to Figure 6 A two-way hydraulic damping device is shown, comprising: a cylinder body (2), a piston rod (1), a piston (7), a positioning ring (4), a mouth sealing ring (5), and a chamber sealing ring (8) , Guide sleeve (3), liquid, nut (6), retaining ring (9). The cylinder body (2) is closed at one end and open at the other end; the guide sleeve (3), the mouth seal (5), the positioning ring (4), the piston (7), the chamber seal (8), the nut (6), the stopper The rings (9) are arranged in the cylinder body (2) in sequence; one end of the piston rod (1) extends into the cylinder body (2), and the guide sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com