A kind of solid expansion tube bending expansion test method under load

A technology of expansion test and bending test, which is applied in the directions of testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, instruments, etc. Full-scale evaluation test and other issues, to achieve the effect of simple and reliable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

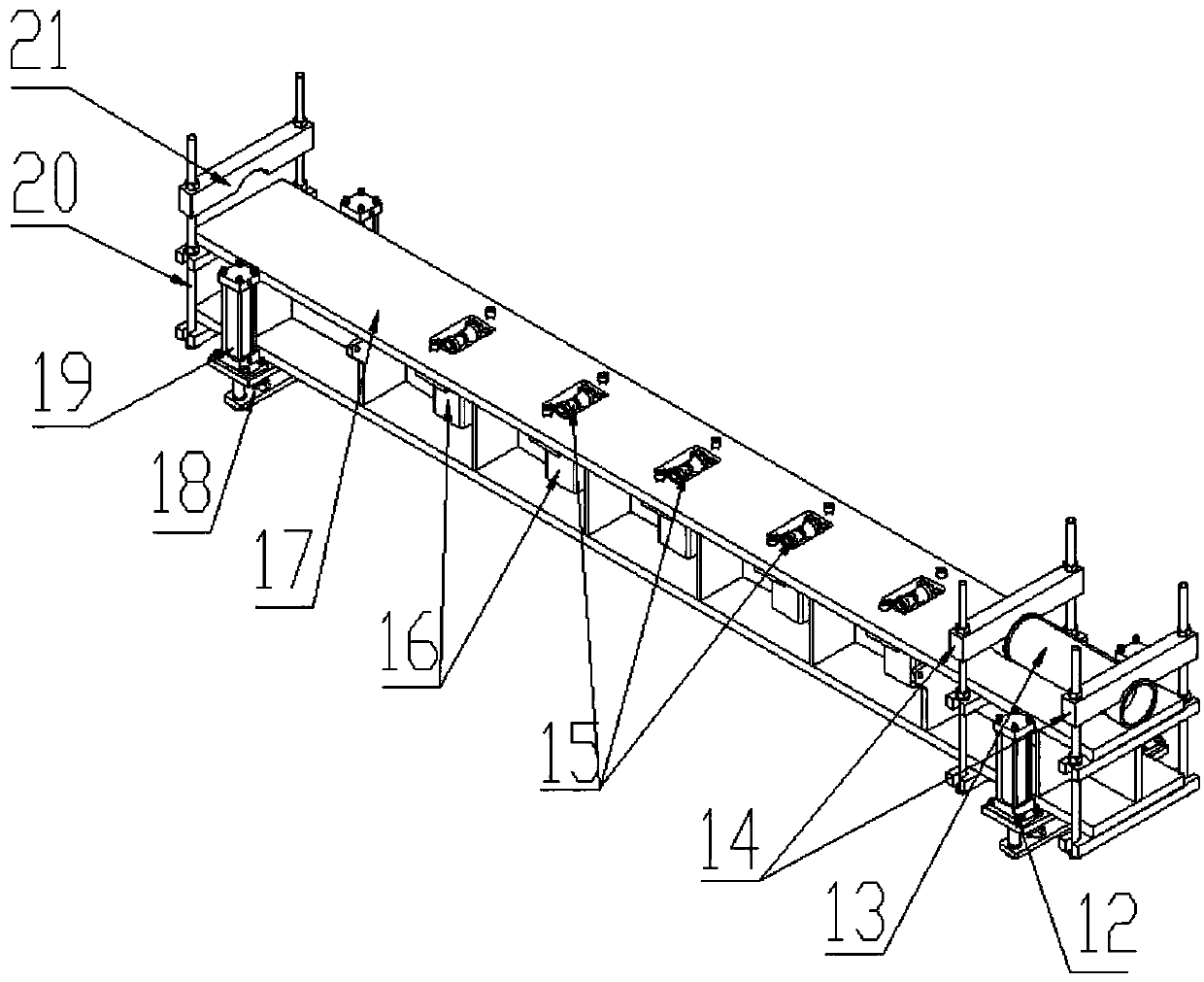

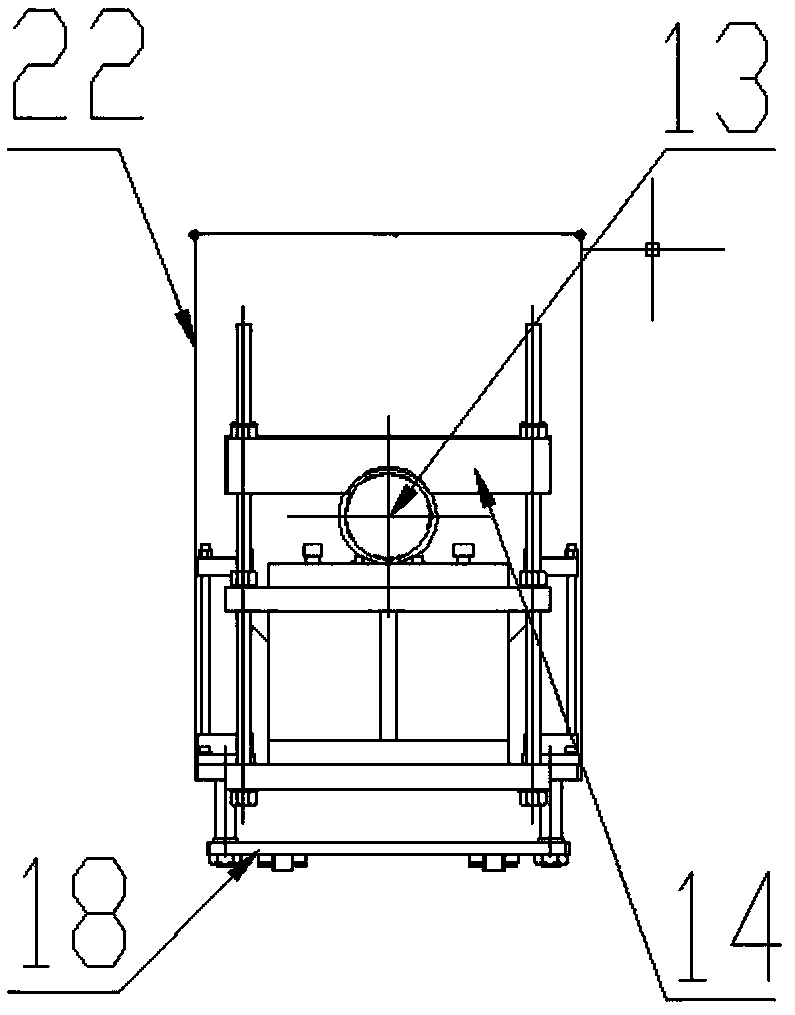

[0030] The solid expansion pipe load bending expansion test device provided in the embodiment is composed of a loading frame and a bending test platform.

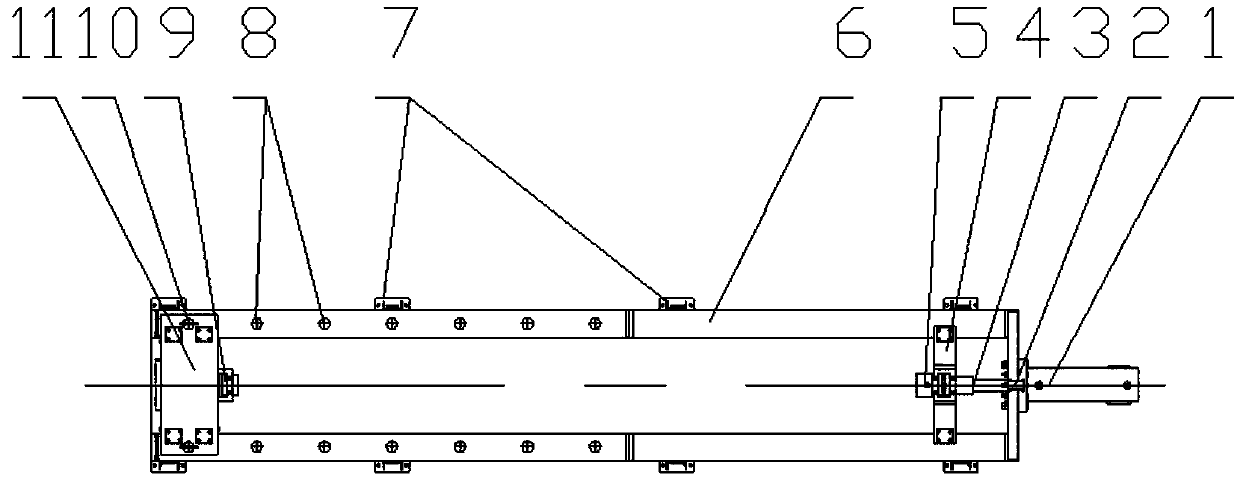

[0031] Such as figure 1 As shown, the loading frame adopts a horizontal structure, which is composed of a hydraulic cylinder 1, a main frame 6 and a frame bracket 7. The main frame 6 adopts a steel welded structure and has a rectangular design, and there is no shelter in the middle. The test platform, the frame material has been annealed and can meet the maximum load of 2000KN. On the right side of the main frame 6, the piston rod 3 is connected to the hydraulic cylinder 1, and the piston rod 3 is connected to the tension chuck 5, which is used to connect the expansion tube for the test and apply axial load. The chuck fixing frame 4 is connected to the main frame 6 Linked to support the tension c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com