Device for overlapping broken strip of plastic extruder

A technology for plastic extruders and strips, which is applied in the field of auxiliary devices, can solve the problems of broken metal parts, movable and fixed knives, scraps of welding electrodes, and scalds by strips, etc., and achieves the effect of simple and reliable device structure and avoiding burn accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described.

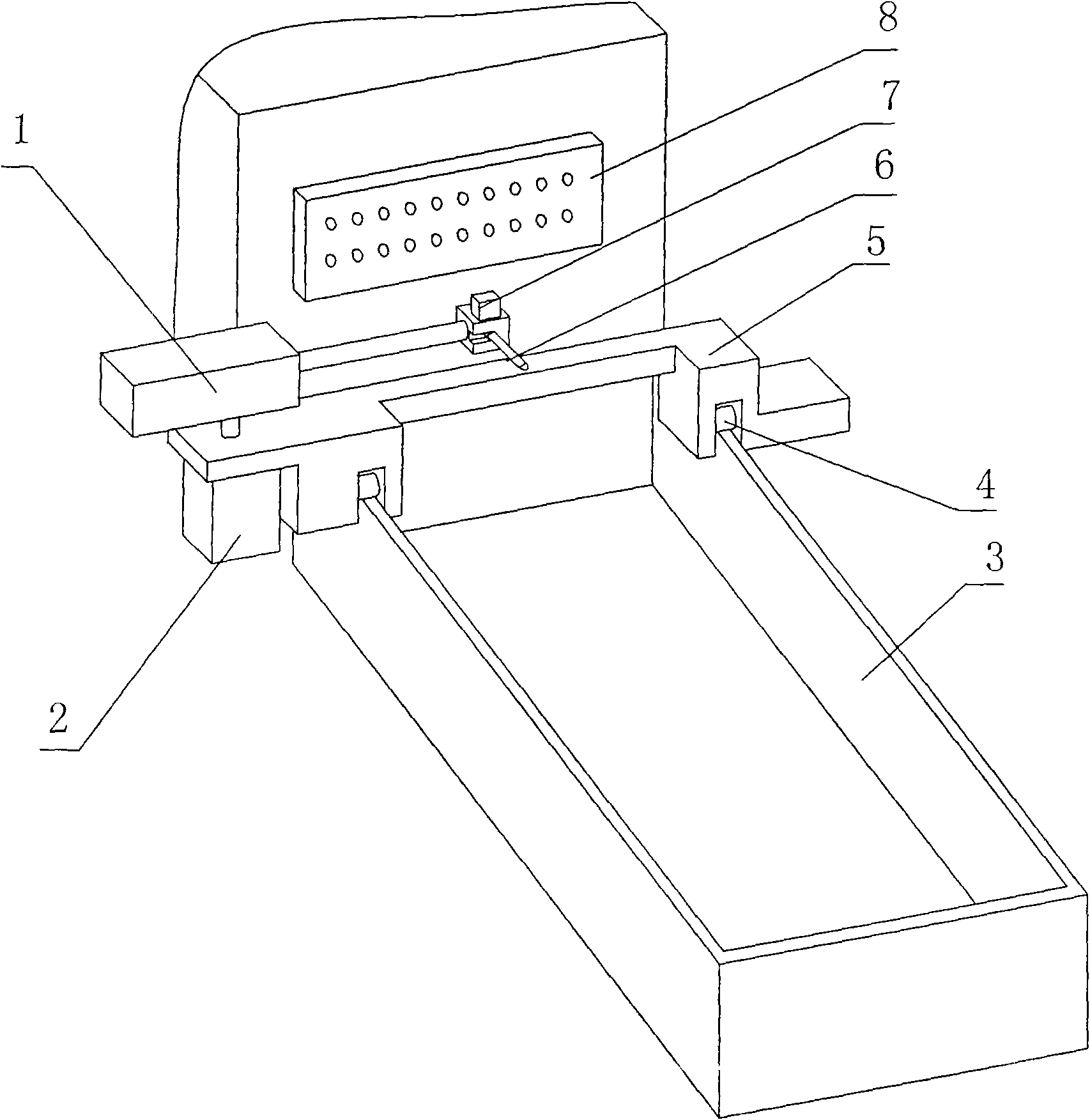

[0020] Such as figure 1 As shown, the device is placed on the water tank 3, the roller frames on the left and right sides of the strip bracket 5 are adjusted to the left and right sides of the water tank 3, the push rod of the horizontal cylinder 1 is initially stretched outside, and the scraper 6 is in the stretch In the straight state, that is, at the position of 0 degrees, the push rod of the vertical cylinder 2 is in the shrinking state. When the strip breaks, you only need to press the start button, and the micro motor 7 rotates to turn the scraper 6 90 degrees to the direction of the conveying movement of the strip. Parallel, the piston of the horizontal cylinder 1 shrinks rapidly, and the vertical cylinder 2 acts to extend the piston. The scraper 6 lifts the broken head extruded from the head of the extruder and lifts it up slightly to avoid scraping other normal ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com