Multi-section fireproof cable

A fireproof cable, multi-segment technology, used in insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of inability to produce large-section and long-length cables, insulation layer shedding, accidents, etc., to increase fire protection. , Improve fire performance and ensure the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

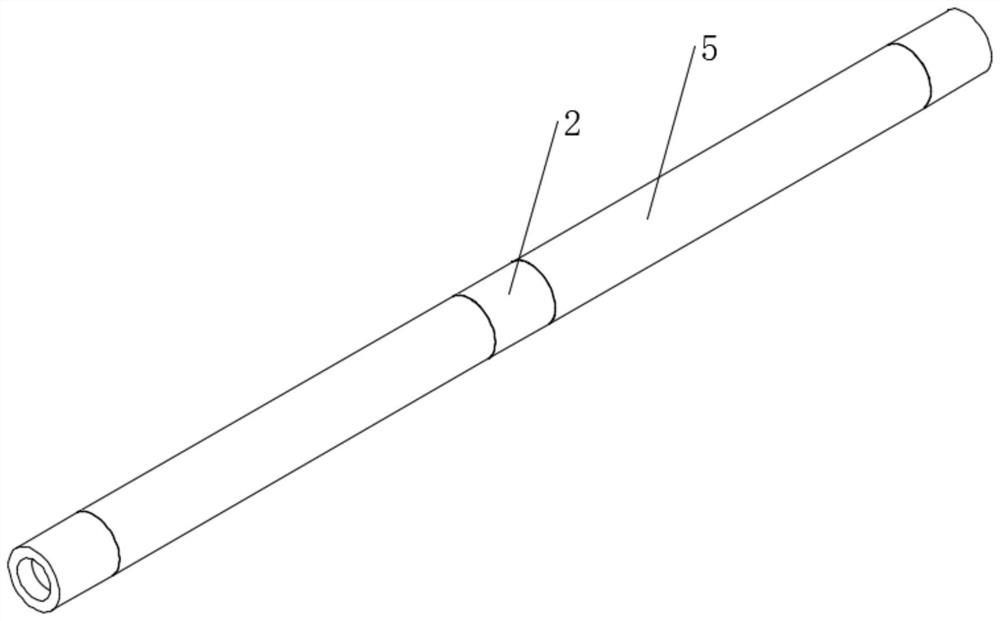

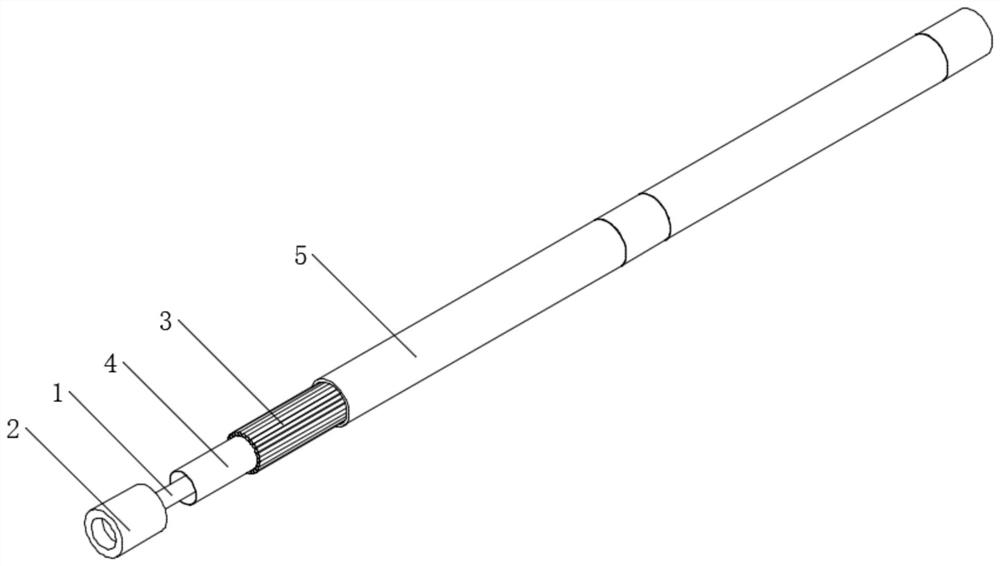

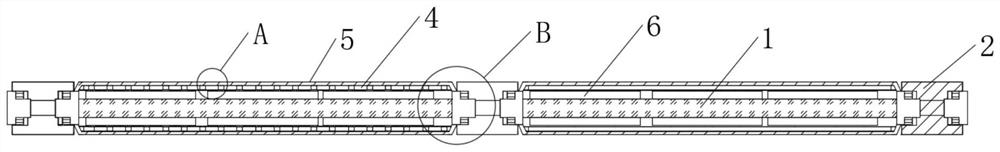

[0042] see Figure 1-3, a multi-segment fireproof cable, comprising a cable main body 1, the cable main body 1 comprising a cable shell and a plurality of high temperature resistant wire cores, and a thermally conductive glue is filled between the wire cores and the cable casing to ensure that the surface of the cable main body 1 forms an elastic support layer 6. It is not easy to deform during the process. The maximum working temperature of the cable body 1 in this scheme is 70-90 degrees Celsius, and a segment ring 2 is connected between two adjacent cable bodies 1. The segment ring 2 includes a fixing ring 201. The fixing ring Both ends of 201 are clamped with elastic joints 202 that match the cable body 1. An elastic ring is fixedly connected to the outer wall of the elastic joint 202. The outer side of the cable body 1 is provided with an insulating protective layer 5. They are respectively fixedly connected with two elastic rings, and a plurality of uniformly distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com