Battery pack with automatic fire extinguishing function

An automatic fire extinguishing and battery pack technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as the breakage of tabs under force, achieve uniform force, improve safety, and reduce the effect of lithium deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

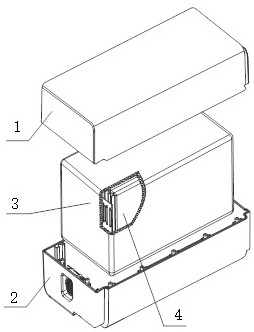

Image

Examples

Embodiment 1

[0031] This embodiment provides a battery pack with a fire extinguishing function, including an upper case and a lower case that are detachably connected. After adjusting the compression rate of the felt, immerse the glass felt in the liquid fire extinguishing agent, absorb it for 30 minutes, take it out for use, and the compression rate is 30%; The casing is fixed to the upper casing, and the output end of the cell pack 4 is drawn out to complete the installation of the battery pack.

Embodiment 2

[0033] This embodiment provides a battery pack with a fire extinguishing function, including an upper case and a lower case that are detachably connected. After adjusting the compression rate of the felt, immerse the glass felt in the liquid fire extinguishing agent, absorb it for 40 minutes and take it out for use, the compression rate is 50%; then wrap the glass felt on the surface of the battery pack and put it into the upper case, and put the lower The casing is fixed to the upper casing, and the output end of the cell pack 4 is drawn out to complete the installation of the battery pack.

Embodiment 3

[0035]This embodiment provides a battery pack with a fire extinguishing function, including a detachably connected upper case and a lower case. First, a glass mat with a porosity of 95% and a pore diameter of 100 μm is used. After adjusting the compression rate of the felt, immerse the glass felt in the liquid fire extinguishing agent, absorb it for 60 minutes, take it out for use, and the compression rate is 5%; then wrap the glass felt on the surface of the battery pack and put it into the upper case, and put the lower The casing is fixed to the upper casing, and the output end of the cell pack 4 is drawn out to complete the installation of the battery pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com