Negative plate, battery and electronic equipment

A technology of negative electrode sheet and battery, which is applied to non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy lithium precipitation of negative electrode sheets, and achieve the effect of improving cycle life and reducing poor kinetics of lithium intercalation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

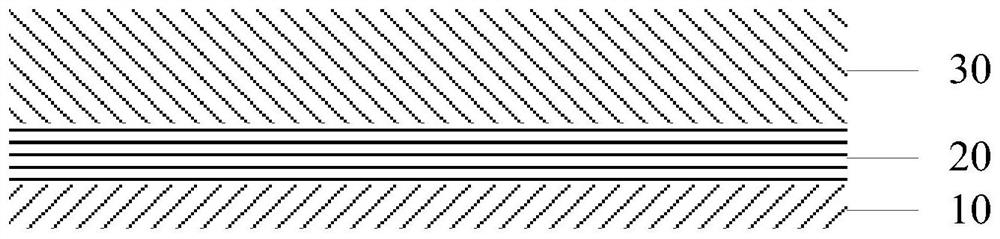

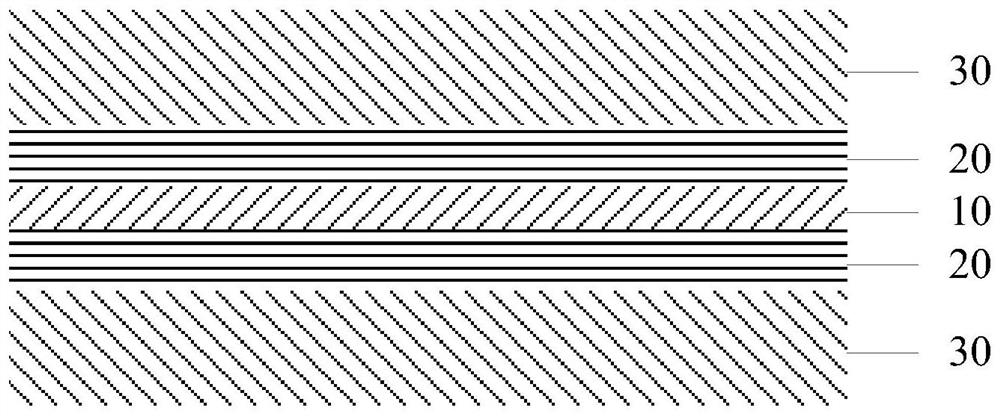

[0038] Embodiment 1: the first coating 20 (layer B) includes 0.1% silicon oxide, the first conductive agent includes 40% carbon black+0.5% multi-wall, and the first auxiliary material includes thickener+binding agent+dispersant , silicon oxide particles D99≤1.5 μm; the second coating 30 (layer A) includes 97.0% graphite, the second conductive agent includes 0.5% carbon black, and the second auxiliary material includes thickener + binder. The half-electric thickness of the first coating 20 is 1.5 μm, and the half-electric thickness of the second coating 30 is 38.6 μm. In the case of 3C step cycles, after testing 800 cycles, the capacity retention rate is 90.5%, and the ratio (expansion change rate) of the final full-charge thickness of the cycle to the initial half-charge thickness of the cycle is 8.1%.

Embodiment 2

[0040] Embodiment 2: the first coating 20 (layer B) includes 3.0% silicon oxide, the first conductive agent includes 40% carbon black+0.02% single-wall+0.8% multi-wall, the first auxiliary material includes thickener+viscosity Binder + dispersant, silicon oxide particles D99≤1.5μm; the second coating 30 (layer A) includes graphite with a content of 96.1%, the second conductive agent includes carbon black with a content of 1%, and the second auxiliary material includes a thickener+ binder. The half-electric thickness of the first coating 20 is 2.0 μm, and the half-electric thickness of the second coating 30 is 35.6 μm. In the case of 5C step cycle, after testing 500 cycles, the capacity retention rate is 82.3%, and the ratio (expansion change rate) of the final full-charge thickness of the cycle to the initial half-charge thickness of the cycle is 9.2%.

Embodiment 3

[0042] Embodiment 3: the first coating 20 (layer B) includes 5.0% silicon oxide, the first conductive agent includes 50% carbon black+0.02% single-wall+1% multi-wall, the first auxiliary material includes thickener+viscosity Binder + dispersant, silicon oxide particles D99≤1.5μm; the second coating 30 (layer A) includes graphite with a content of 96.1%, the second conductive agent includes carbon black with a content of 1%, and the second auxiliary material includes a thickener+ binder. The half-electric thickness of the first coating 20 is 2.0 μm, and the half-electric thickness of the second coating 30 is 30.0 μm. In the case of 2C step cycles, after testing 600 cycles, the capacity retention rate is 82.1%, and the ratio of the final fully charged thickness to the initial half-charged thickness (expansion change rate) is 8.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com