Roof heat insulation system

A technology of thermal insulation and thermal insulation coating, applied in roof insulation materials, roofing, roof covering and other directions, can solve the problems of lack of thermal insulation, self-heavy, unusable houses, etc. Low, the effect of enhancing the waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

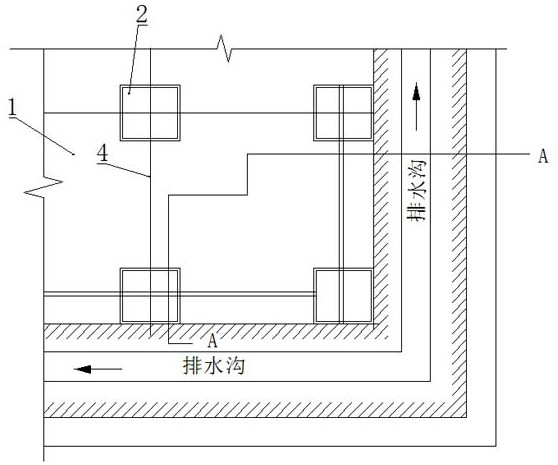

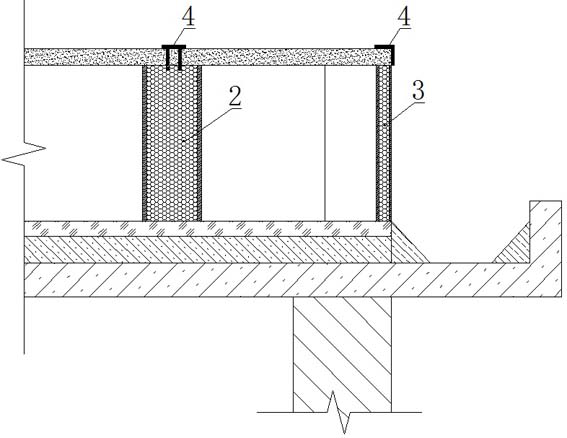

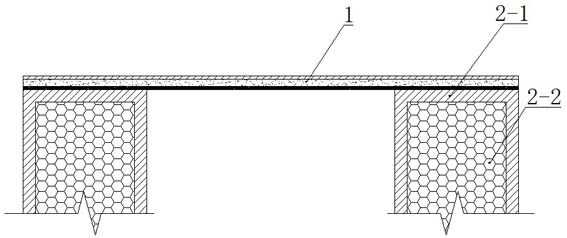

[0037] Such as Figure 1-2 As shown, the present invention discloses a roof heat insulation and heat preservation system. The system is provided with a plurality of legs 2 above the roof waterproof felt, and each group of four legs forms a rectangular combination (a square is a special case of a rectangle, which is used here Rectangle, including both square and rectangle, refers to a larger range.), add a piece of fiber cement board 1 above each rectangular leg combination, that is, below the four corner points of each fiber cement board Four outriggers are set, and multiple fiber cement boards are spliced together to form a thermal insulation roof system, and the joints between adjacent fiber cement boards are sealed with sealing tape. Fiber cement board has the advantages of not easy to deform, not easy to warp and light weight, it is very suitable for heat insulation and sun protection layer of the roof. In order to reduce the load of the roof, the outriggers are made of...

Embodiment 2

[0040] Regardless of winter heating (such as in southern China), the following measures can be taken:

[0041] 1. Remove the windshield;

[0042] 2. Remove the heat absorbing layer (black paint) of the fiber cement board and windshield;

[0043] 3. Remove the sealing tape, and only keep the reflective layer (white or silver coating) of the fiber cement board;

[0044] 4. The height of the legs is slightly higher than that of Embodiment 1.

Embodiment 3

[0046] Such as image 3 As shown, in order to reduce the load-bearing of the roof, the outriggers are made of foam plastic, so that the roof outriggers have the characteristics of light weight, heat insulation, sound absorption, and shock absorption. In order to achieve the purpose of waterproofing and fire prevention, a layer of inorganic coating is provided on the outside of the foam plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com