Correction equipment for steel structure correction machining

A steel structure and equipment technology, which is applied in the field of steel structure correction, can solve problems such as poor correction effect, bending, and size difference of H-shaped steel materials, and achieve the effects of improving the effect, avoiding deformation, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

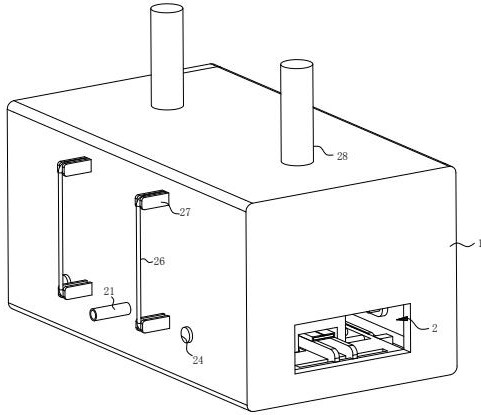

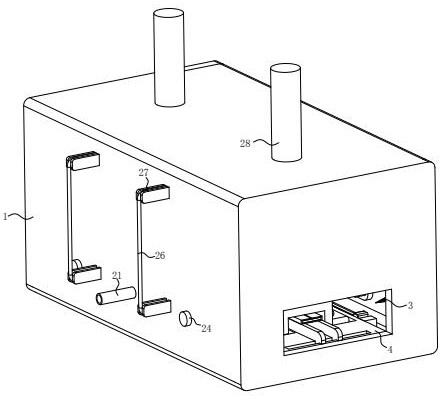

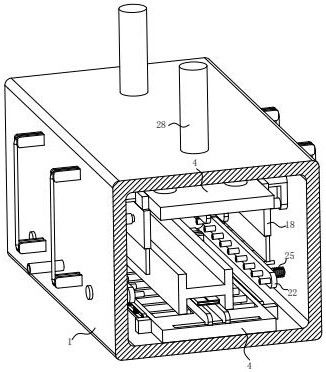

[0028] see Figure 1-9 , the present invention provides a technical solution: a straightening device for steel structure straightening processing, comprising a straightening box 1, one end of the straightening box 1 is provided with a feeding port 2, the other end is provided with a discharging port 3, and the straightening box 1 is provided with There are two first support plates 4, the two first support plates 4 are arranged up and down, the bottom first support plate 4 is fixedly connected to the inner bottom of the correction box 1, and the bottom first support plate 4 is internally provided with H-shaped steel for conveying. The opposite surfaces of the two first support plates 4 are connected with a support mechanism for propping up the inner sidewall of the H-shaped steel, and the upper and lower support mechanisms are used for positioning the upper and lower grooves of the H-shaped steel. The top of the support mechanism is connected with a pressing mechanism for horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com