Preparation method of Ti6Al4V alloy bar with high sound velocity uniformity

A technology for alloy rods and uniformity, applied in the field of titanium alloy processing, can solve problems such as large fluctuations in sound velocity, poor consistency of microstructure and mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

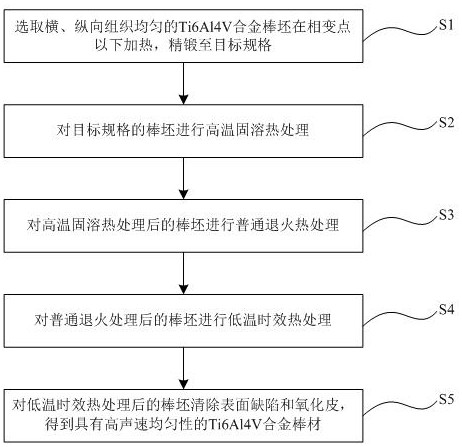

[0029] The invention provides a preparation method of a Ti6Al4V alloy bar with high sound velocity uniformity, see figure 1 , which includes the following steps:

[0030] Step 1, precision forging:

[0031] The original Ti6Al4V alloy round billet with uniform horizontal and vertical structure is placed in a stepping resistance furnace, heated at 40 ° C ~ 100 ° C below the phase transition point, and passed through 1 ~ 2 fires, and the number of fine forging passes per fire is 3 ~ 5 passes, the precision forging deformation of each pass is 5%~30%, and the precision forging reaches the target specification; among them, the total precision forging deformation is 41.0%~91.3%, and only one fire precision forging is required when the total deformation is less than 79.5%. , when the total deformation is greater than 79.5%, two-fire precision forging is required;

[0032] Step 2, high temperature solution heat treatment:

[0033] The billet obtained in step 1 is placed in a box-typ...

Embodiment 1

[0042] This embodiment provides a method for preparing a Ti6Al4V alloy rod with high sound velocity uniformity, which specifically includes the following steps:

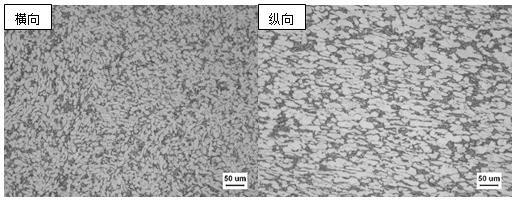

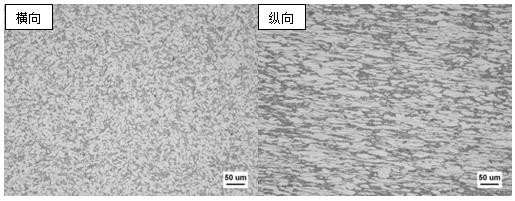

[0043] Step 1, make the Ti6Al4V alloy billet with a uniform horizontal and vertical structure of Φ95mm (see the high-magnification structure diagram of the horizontal and vertical directions). figure 2 ) placed in a stepping resistance furnace, heated at 40°C below the phase transition point, passed through 2 fires, each fire forging pass is 5 passes, each pass is 15%~30% deformation, and precision forging to Φ28mm , the total deformation is 91.3%;

[0044] Step 2, place the Φ28mm billet obtained in step 1 in a box-type heat treatment furnace, and perform high-temperature solution heat treatment at 20°C below the phase transition point, holding time for 1h, and air-cooled after being released from the furnace;

[0045] Step 3, placing the Φ28mm billet after the high temperature solution heat treatment in step 2 in ...

Embodiment 2

[0050] This embodiment provides another method for preparing a Ti6Al4V alloy rod with high sound velocity uniformity, which specifically includes the following steps:

[0051] Step 1, make the Ti6Al4V alloy billet with a uniform horizontal and vertical structure of Φ95mm (see the high-magnification structure diagram of the horizontal and vertical directions). figure 2 ) placed in a stepping resistance furnace, heated at 70°C below the phase transition point, passed through 2 fires, each fire forging pass is 3 passes, each pass 10%~25% deformation, precision forging to Φ42mm , the total deformation is 80.5%;

[0052] Step 2, place the Φ42mm billet obtained in step 1 in a box-type heat treatment furnace, and perform high-temperature solution heat treatment at 40°C below the phase transition point, holding time for 1.5h, and air-cooled after being released from the furnace;

[0053] Step 3, place the Φ42mm billet after the high-temperature solution heat treatment in step 2 in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com