Vacuum smelting technology of hafnium containing nickel base casting high temperature alloy K488 reverse material alloy

A high-temperature alloy and vacuum melting technology, applied in the field of alloy melting, can solve problems such as the influence of the mechanical properties of the alloy, the specific gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The selection of returned materials includes:

[0081] (1) Waste materials of K488 master alloy;

[0082] (2) The gating system of K488 waste parts castings and performance test bars, and the runner when pouring master alloys.

[0083] Sand blowing is performed on all returned materials to clean up the sticky iron, inclusions, sand inclusions, etc. on the surface.

[0084] The smelting equipment adopts 25kg, ZG200 vacuum induction furnace.

[0085] The return material is smelted first.

[0086] Hafnium (Hf)-containing nickel-based casting superalloy K488 return material vacuum melting process, including melting, refining, alloy freezing treatment, pouring, alloy composition adjustment process steps.

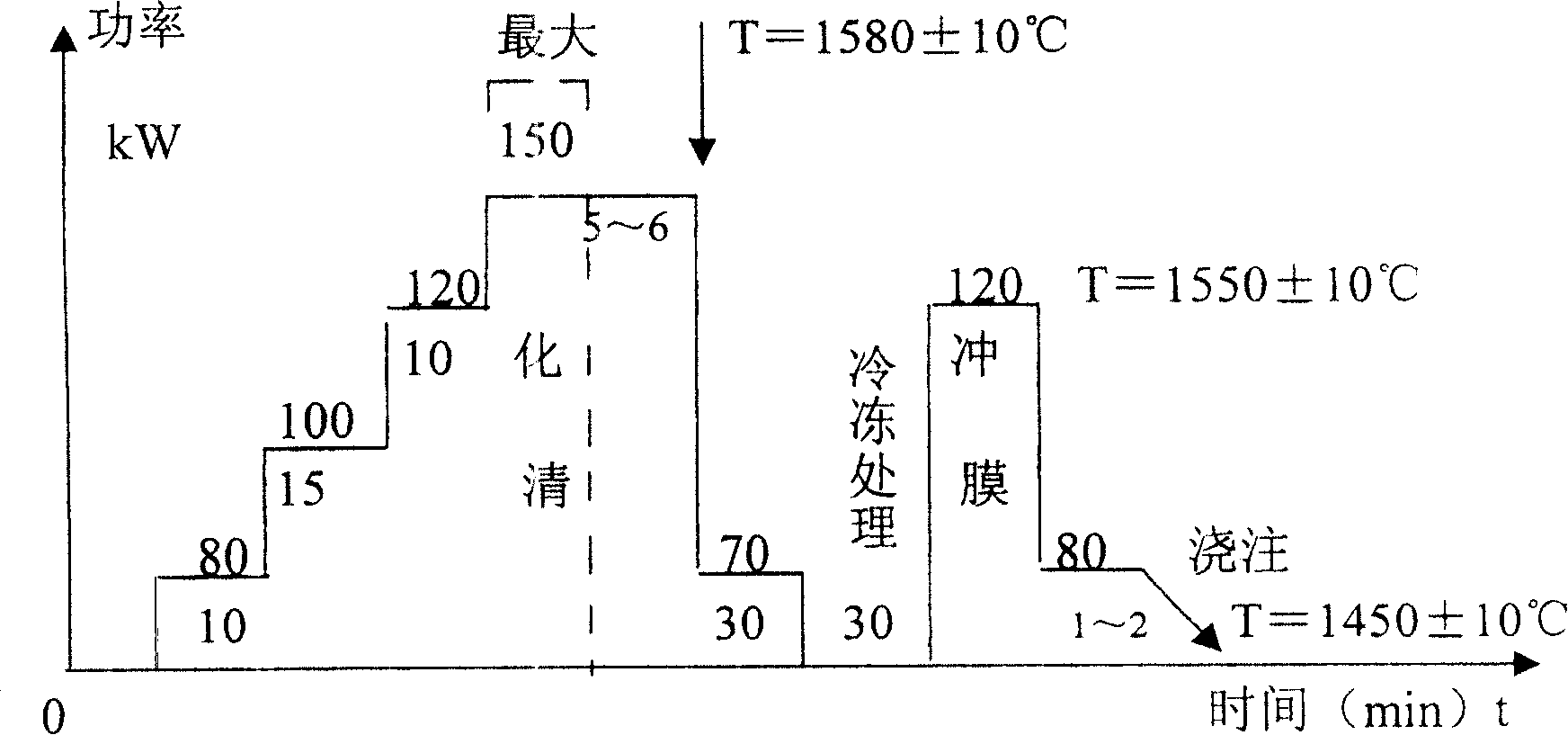

[0087] The power curve of K488 alloy return material smelting process is shown in figure 1 .

[0088] (1) melting

[0089] When the vacuum degree reaches ≤1.33Pa, it can be powered and melted. Except for cold furnaces, which start to be powered from 80±10kW, hot fur...

Embodiment 2

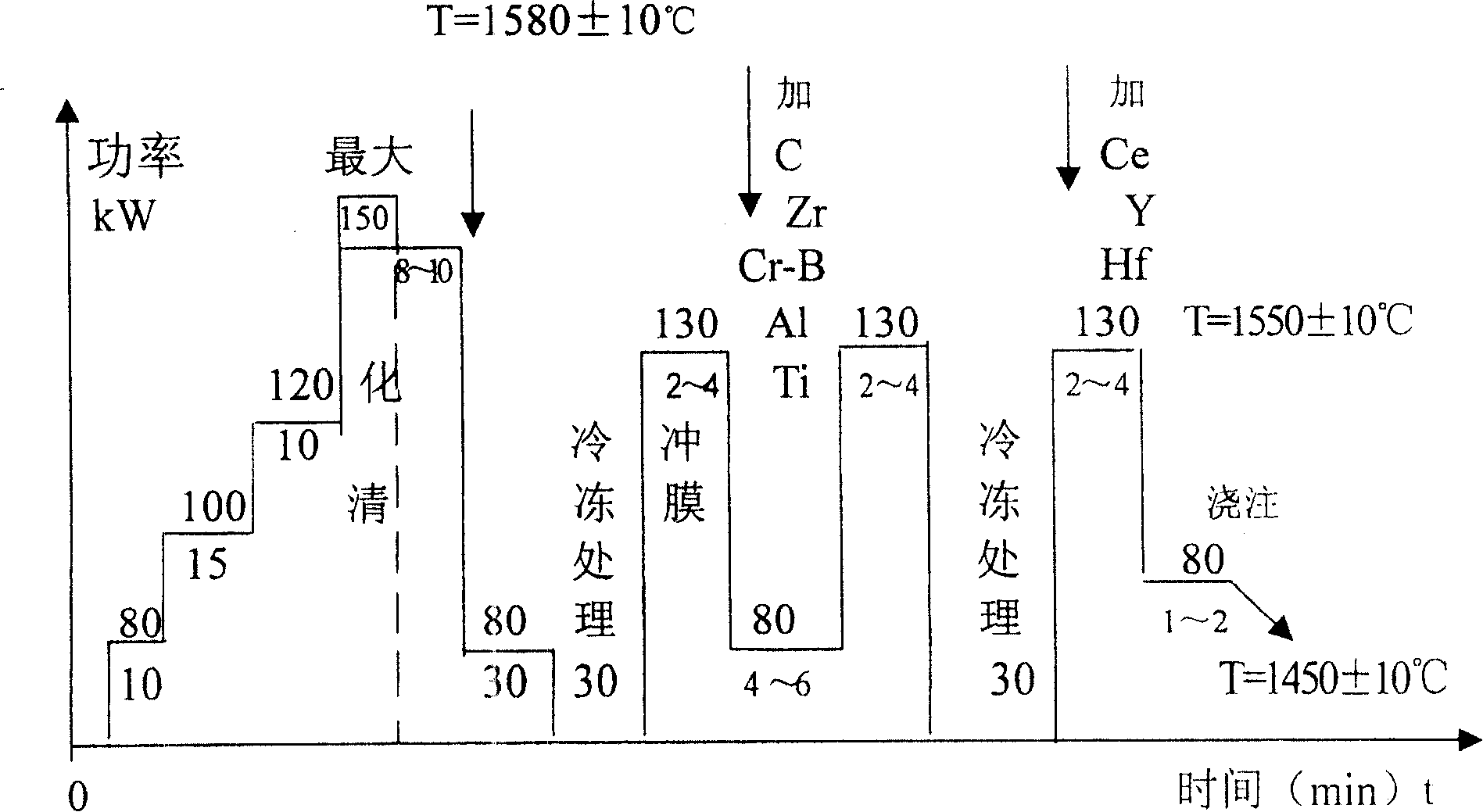

[0167] The implementation process steps are the same as in Example 1. In the stage of smelting and returning the alloy product, two alloying treatments specifically adjust the alloy composition according to the following proportioning (weight percentage):

[0168] C0.04, Cr16.30, Co11.50, W4.70, Mo1.60, Al3.00, Ti5.00, Nb0.30, Hf0.30, B0.06, Y0.03, Ce0.015, Zr0. 05. The balance is mainly Ni.

Embodiment 3

[0170] The implementation process steps are the same as in Example 1. In the stage of smelting and returning the alloy product, two alloying treatments specifically adjust the alloy composition according to the following proportioning (weight percentage):

[0171] C0.09, Cr15.40, Co10.00, W5.90, Mo2.10, Al2.80, Ti4.20, Nb0.10, Hf0.20, B0.10, Y0.03, Ce0.015, Zr0. 05. The balance is mainly Ni.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com