Sliding damping support for in-situ replacement of existing plant roof truss and construction method

A shock-absorbing support and construction method technology, applied in the direction of earthquake resistance, building type, construction, etc., can solve problems such as difficult offset or release of horizontal force, potential safety hazards, damage to roof truss supports, etc., to achieve simple construction and improve mission The effect of long life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

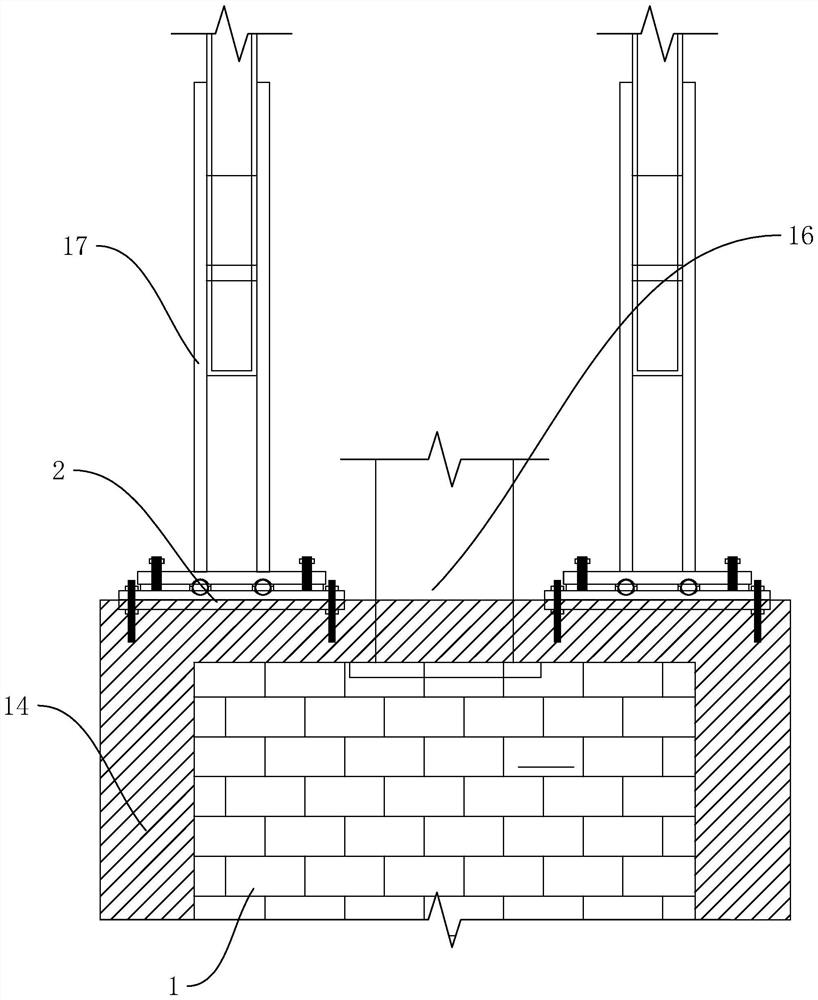

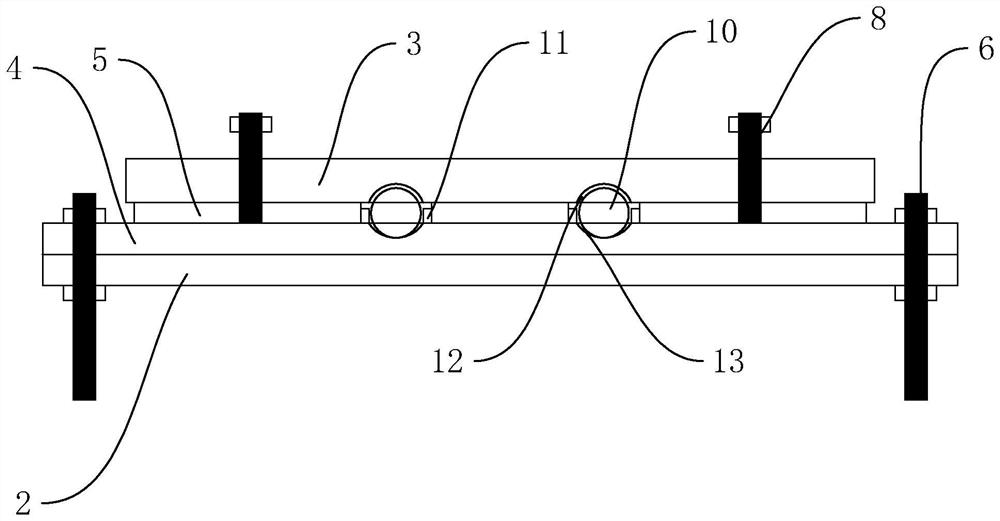

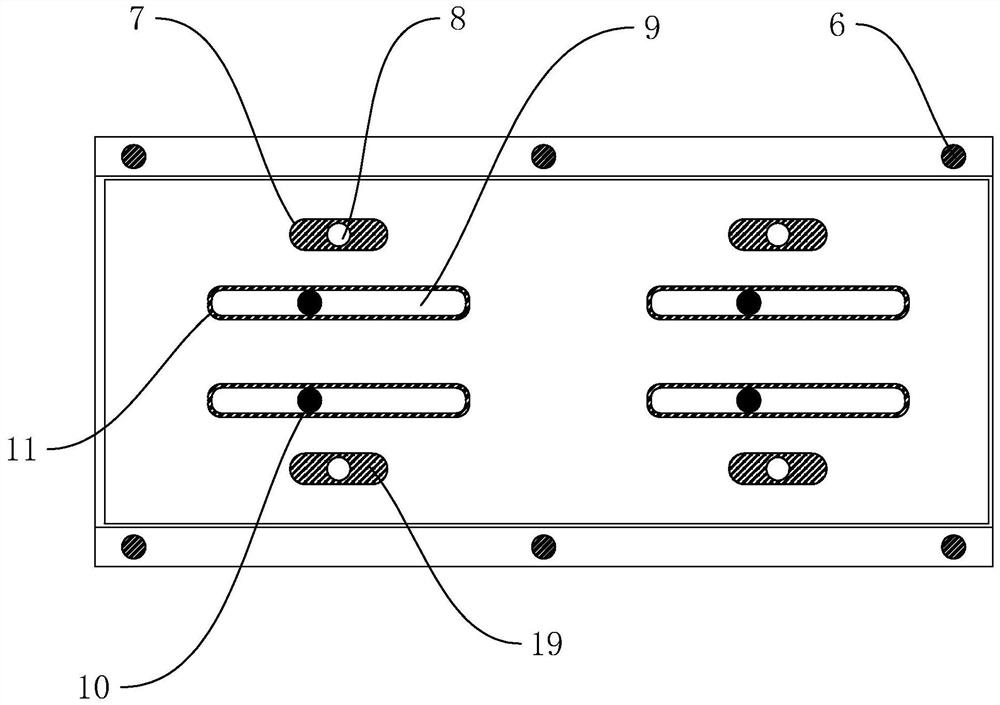

[0041] Attached to the following Figure 1-4 This application will be described in further detail.

[0042] The embodiment of the present application discloses a sliding shock-absorbing support and a construction method for exchanging the original position of the existing factory building frame.

[0043] A sliding shock-absorbing bearing that is replaced by the original position of the existing factory building frame, refer to figure 1 , figure 2 and image 3 , including the masonry column 1, the positioning plate 2 and the object plate 3 fixed on the masonry column 1, and the connecting plate 4 fixed on the positioning plate 2 and the PTFE plate 5 set on the connecting plate 4 , Since the connecting plate 4 is fixed at the end of the positioning plate 2 away from the masonry column 1, the connecting plate 4 is inserted with fixing bolts 6, and the fixing bolts 6 penetrate through the connecting plate 4 and the positioning plate 2, and the fixing by the fixing bolts 6 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com