Novel precision machining tool bar with air discharge ducts

A technology of precision machining and exhaust grooves, applied in the direction of tool clips, etc., can solve the problems of increasing the adhesion between the blade and the blade installation area, poor wear resistance of white steel, low product output rate, etc., and achieves convenient and quick installation and disassembly. , The effect of reducing production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

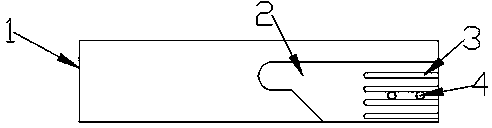

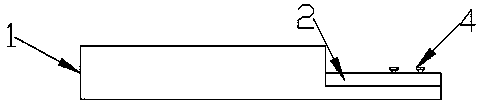

[0015] A new type of precision machining tool holder, such as figure 1 , figure 2 As shown, it includes a knife holder body 1, a blade installation area 2, an exhaust groove 3, and an inner hexagonal screw 4; the blade installation area 2 is welded on one side of the knife holder body 1 by a special welding process, and the exhaust groove 3 On the surface of the blade installation area 2, the hexagon socket head screw 3 is installed in the blade installation area 2, which forms a novel precision-machined tool bar with an exhaust groove.

[0016] The specific operation is as follows: First unscrew the two hexagonal screws 3, install the blade on the blade installation area 2, and tighten the two hexagonal screws 4 to firmly hold the blade, and then install the tool holder body 1 with the blade installed on the device , just turn on the device, the price is moderate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com