Dry-wet combined desulfurization dedusting device resistant dewing of fan

A technology for desulfurization and dust removal and dust removal devices, which is applied in the direction of combined devices, gas treatment, membrane technology, etc., can solve the problems of fan impeller dust accumulation, high flue gas temperature, and low flue gas temperature drop, so as to prevent condensation and improve the treatment process Simple, mission-life-extending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

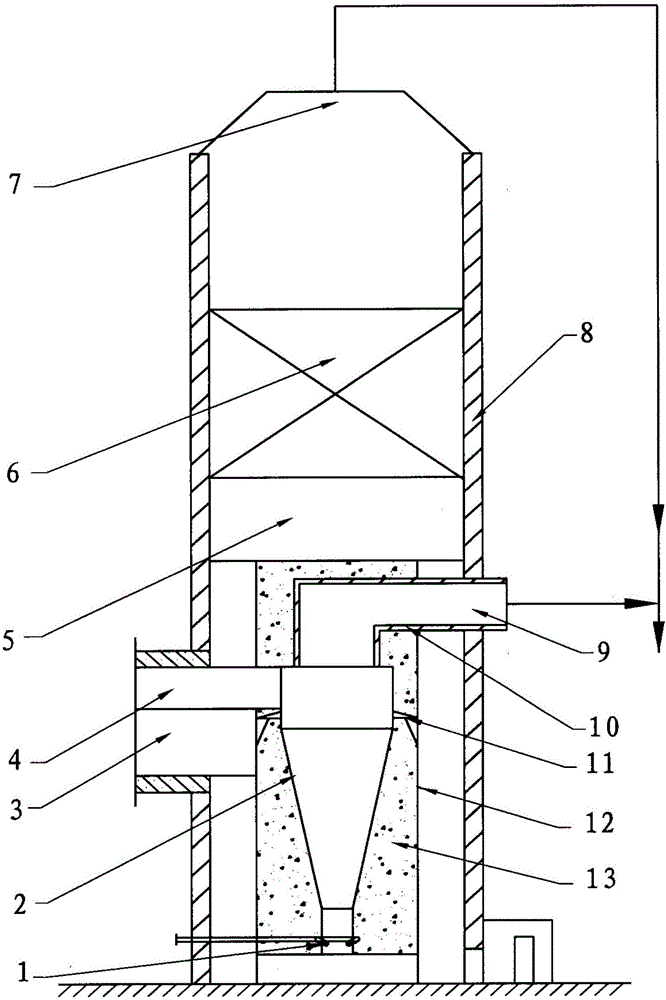

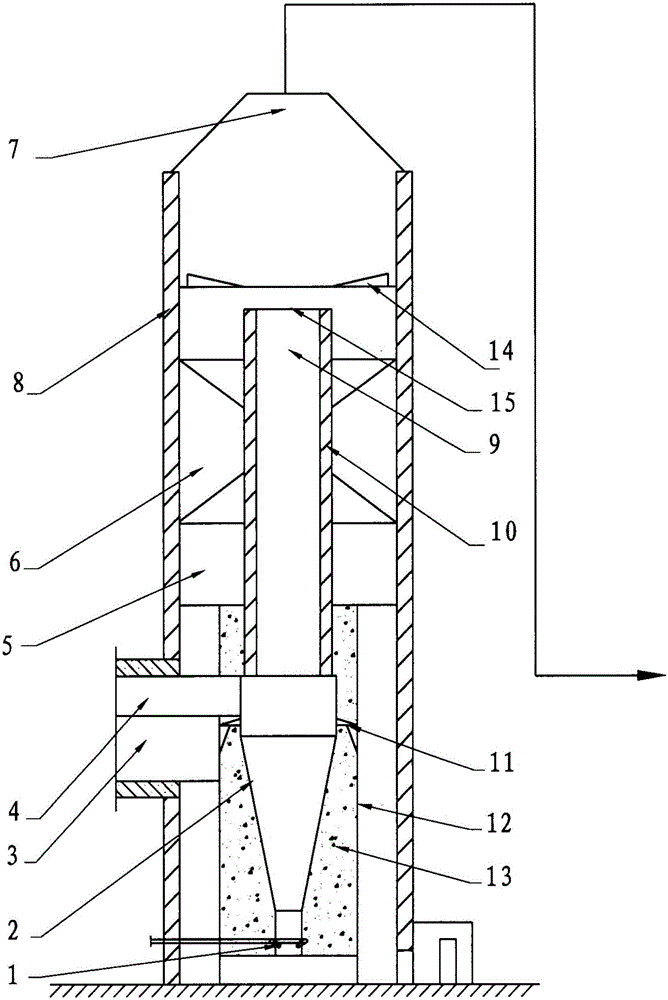

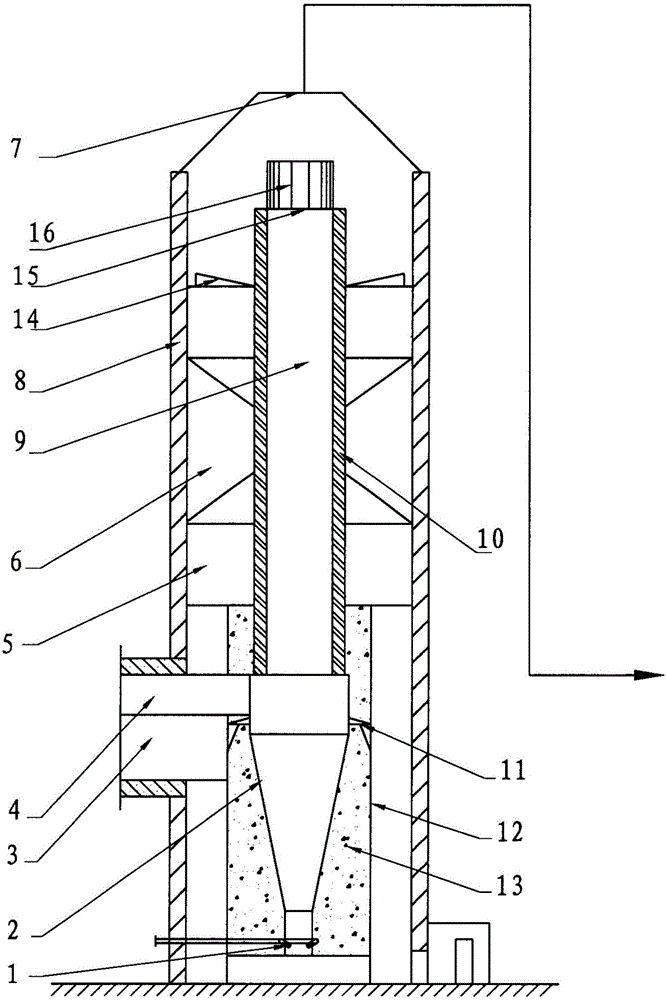

[0017] Such as figure 1 , The present invention consists of a wet desulfurization and dust removal device and a dry dust removal device. The dry dust removal device is composed of an inlet flue 4, a dry dust collector 2 and an outlet flue 9. The dry dust collector 2 can be a single cyclone separation dust collector, Multi-tube cyclone separation dust collector, bag filter, electric dust collector and other dry dust collectors.

[0018] The wet desulfurization and dust removal device consists of an inlet flue 3, a wet desulfurization and dust removal tower 5, and an outlet flue 7. The wet desulfurization and dust removal tower 5 can be a spray tower, a packed tower, a swirling plate tower, a turbulent plate tower, a sieve plate tower, and turbulent flow. Plate towers such as towers, turbulence towers, bubble towers, and other wet desulfurization and dust removal towers.

[0019] A sealed inner cylinder 12 is arranged inside the wet desulfurization and dust removal tower 5, the dry d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com