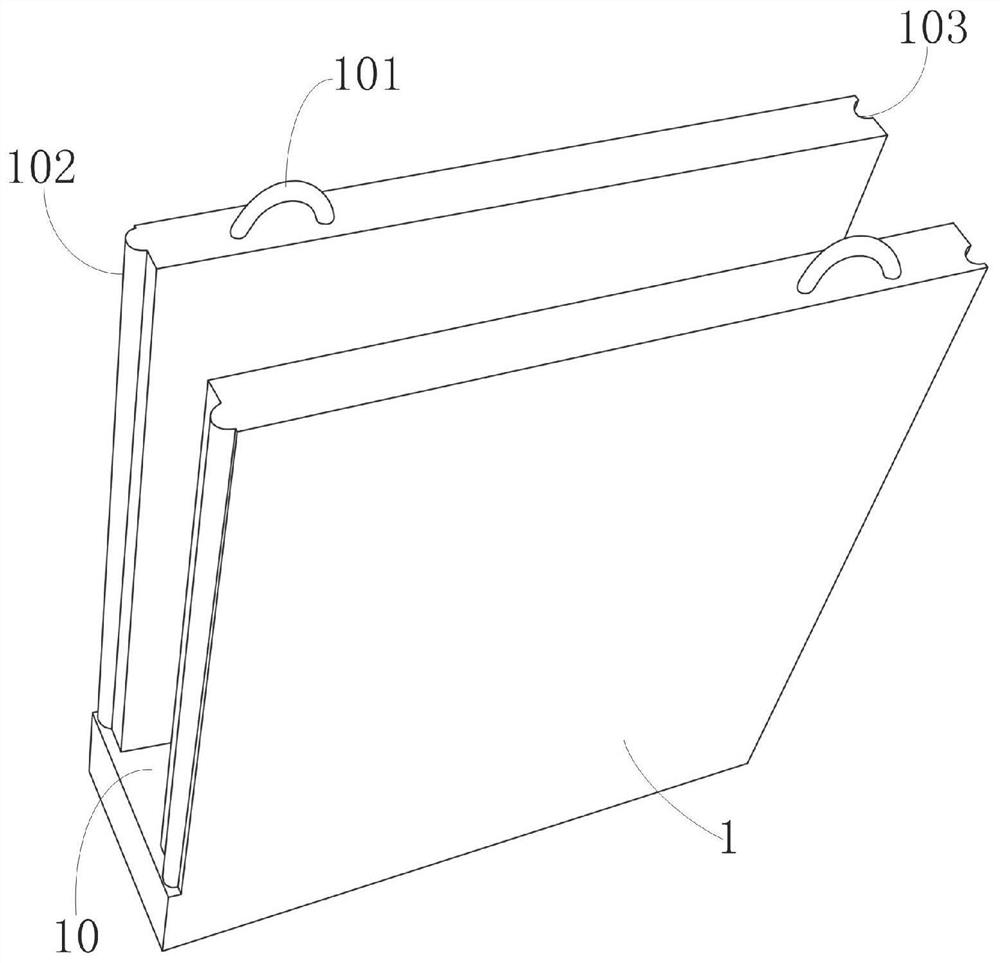

Prefabricated and assembled composite vibration isolation barrier and construction method thereof

A prefabricated assembly and composite technology, applied in the direction of noise absorption devices, buildings, etc., can solve the problems of difficult maintenance and unfavorable stability of the surrounding rock and soil, so as to reduce the difficulty of construction, reduce the number of times and costs, and extend the mission The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The embodiment of the present invention discloses a prefabricated assembled composite vibration isolation barrier and its construction method. The working principle is as follows:

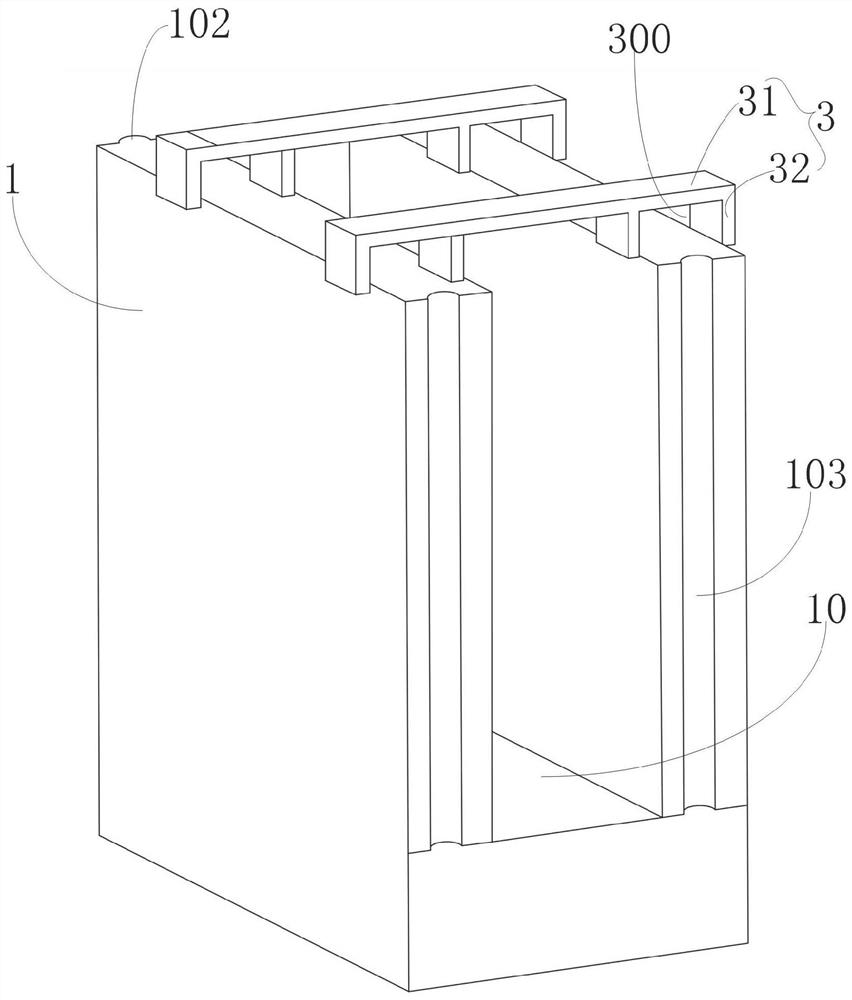

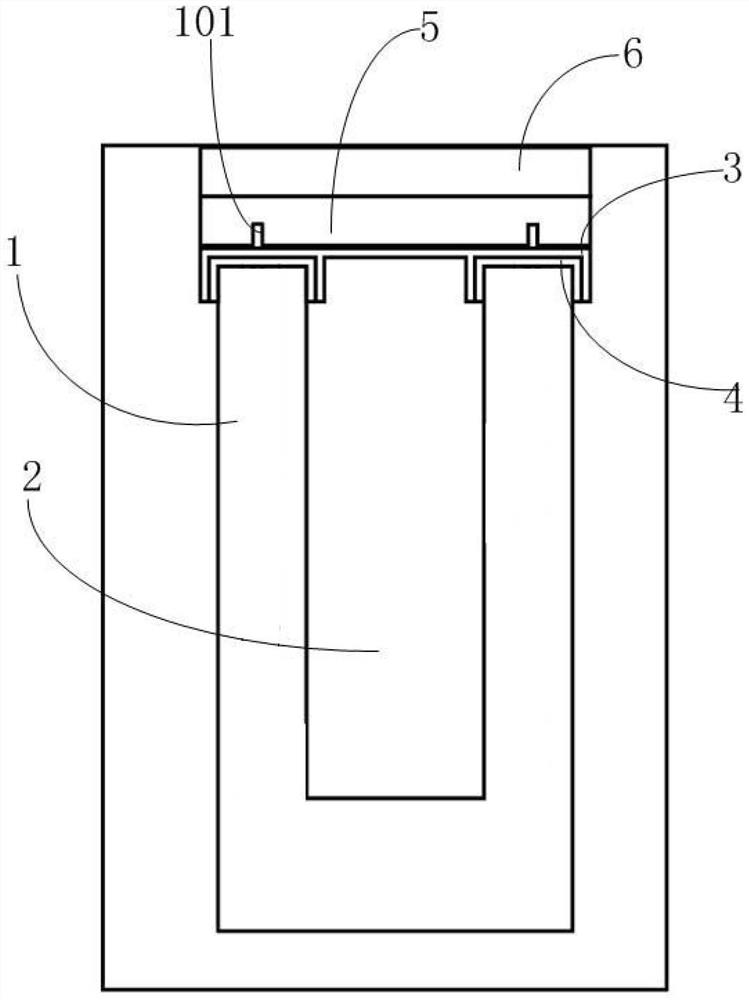

[0090] S1, the factory makes "U"-shaped precast concrete tanks 1, and there are multiple spacers 3 at the top opening of each "U"-shaped precast concrete tank 1, and multiple spacers 3 along the "U" The longitudinal direction of the precast concrete tank 1 is distributed at intervals, and each spacer 3 spans the top opening of the corresponding "U"-shaped precast concrete tank 1, and the distance between the spacer 3 and the "U"-shaped precast concrete tank 1, the joint at the top of the side plate is filled with a flexible piece 4;

[0091] S2. Dig a storage tank on the set ground so that the tank body of the storage tank is 200mm deeper than the height of the "U"-shaped prefabricated concrete tank body 1, and level the tank bottom of the storage tank at the same time;

[0092] S3, hoistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com