Method and device for determining axial force loss of ball head connecting structure of front steering knuckle

A connection structure and front steering technology, applied in the automotive field, can solve problems such as vehicle out of control, hidden safety hazards, threats to life and property safety, etc., and achieve the effects of fast calculation speed, strong applicability, and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

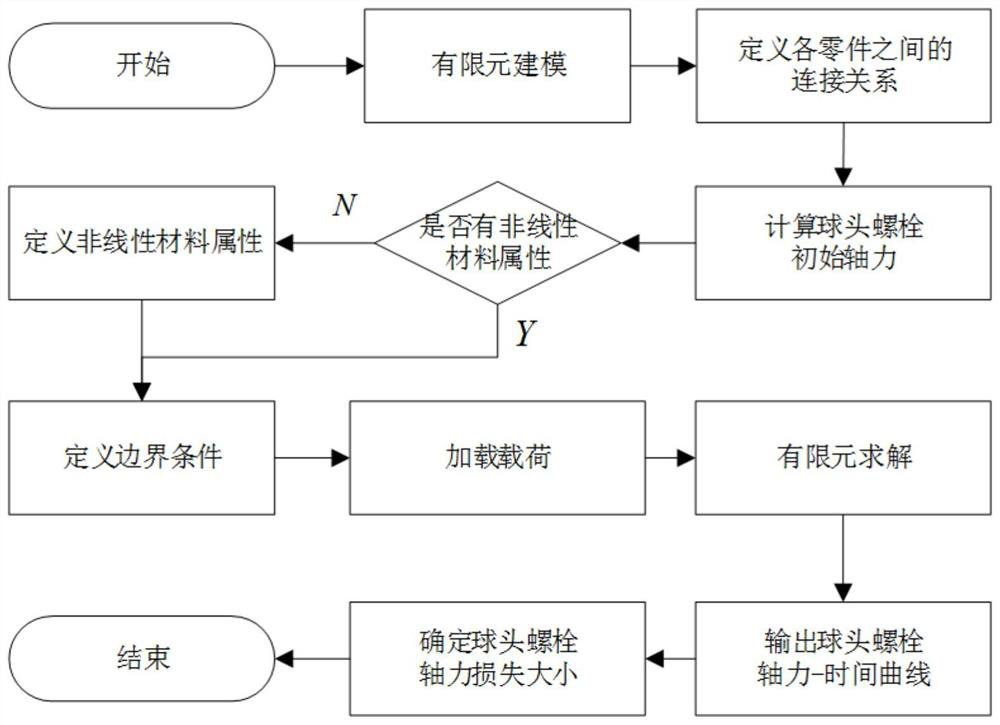

[0081] figure 1 A flowchart of a method for determining the axial force loss of a ball joint connection structure of a front steering knuckle provided in Embodiment 1 of the present invention. To execute, the device can be implemented in software and / or hardware, such as figure 1 As shown, the method specifically includes the following steps:

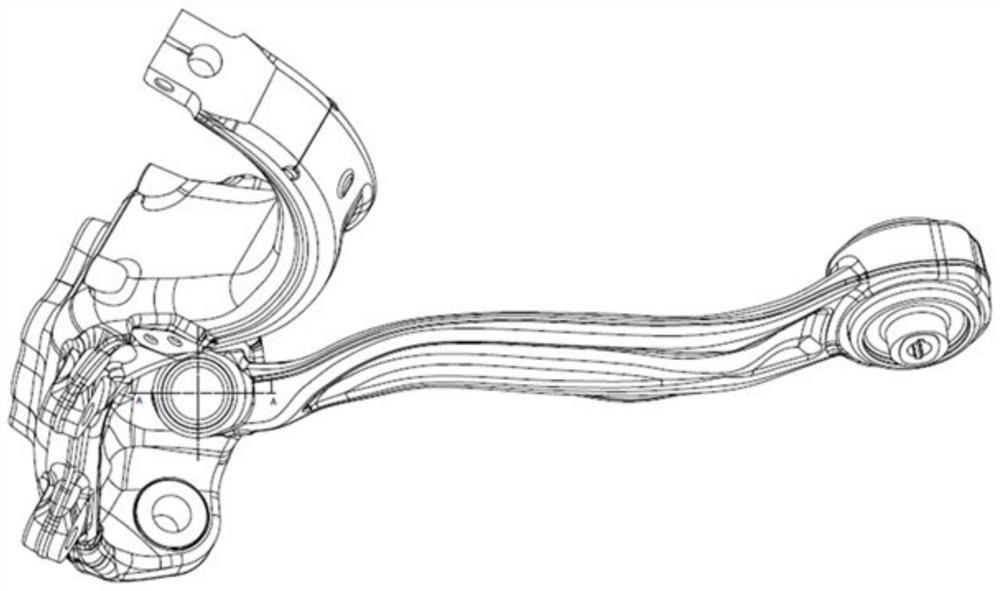

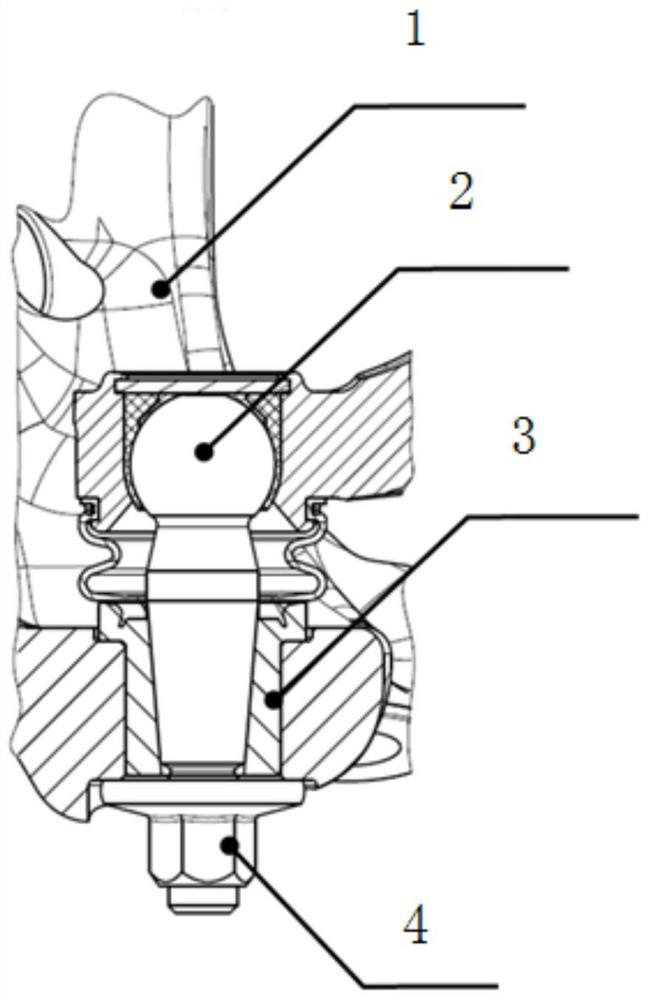

[0082] see Figure 2a and Figure 2b , step 1, establish the finite element model of steering knuckle 1, ball stud 2, bushing 3 and nut 4;

[0083] The finite element model ensures that the model position of each part is consistent with the actual assembly position, and there is no structural interference between the parts.

[0084] The steering knuckle 1 is modeled using second-order tetrahedral elements, and the modeling mesh size is 1-2 mm.

[0085] The ball stud 2 and the bushing 3 are obtained by rotating a two-dimensional model, which can ensure a good contact effect on the contact surface. The modeling adopts hexahedral elem...

Embodiment 2

[0140] Image 6 This is a schematic structural diagram of a device for determining the axial force loss of a ball joint connection structure of a front steering knuckle provided in the second embodiment of the present invention. This embodiment can be applied to the case of determining the axial force loss of the front steering knuckle ball joint structure. The device can be implemented in software and / or hardware. The device can be integrated into any device provided for determining the front steering knuckle ball joint structure Axial force loss in functional devices.

[0141] The device for determining the axial force loss of the ball joint connection structure of the front steering knuckle includes:

[0142] Establish a finite element model module for establishing finite element models of steering knuckle 1, ball stud 2, bushing 3 and nut 4;

[0143] Define the connection relationship module, which is used to define the connection relationship of each part;

[0144] Cal...

Embodiment 3

[0156] Figure 7 It is a schematic structural diagram of a computer device in Embodiment 3 of the present invention. Figure 7 A block diagram of an exemplary computer device 12 suitable for use in implementing embodiments of the present invention is shown. Figure 7 The computer device 12 shown is only an example, and should not impose any limitations on the functionality and scope of use of the embodiments of the present invention.

[0157] like Figure 7 As shown, computer device 12 takes the form of a general-purpose computing device. Components of computer device 12 may include, but are not limited to, one or more processors or processing units 16 , system memory 28 , and a bus 18 connecting various system components including system memory 28 and processing unit 16 .

[0158] Bus 18 represents one or more of several types of bus structures, including a memory bus or memory controller, a peripheral bus, a graphics acceleration port, a processor, or a local bus using an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com