Joint debugging mechanism and sewing machine

A sewing machine and joint debugging technology, which is applied in the direction of sewing machine components, cloth pressing mechanism, sewing equipment, etc., can solve the problems of unfavorable sewing machine miniaturization and low-cost development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

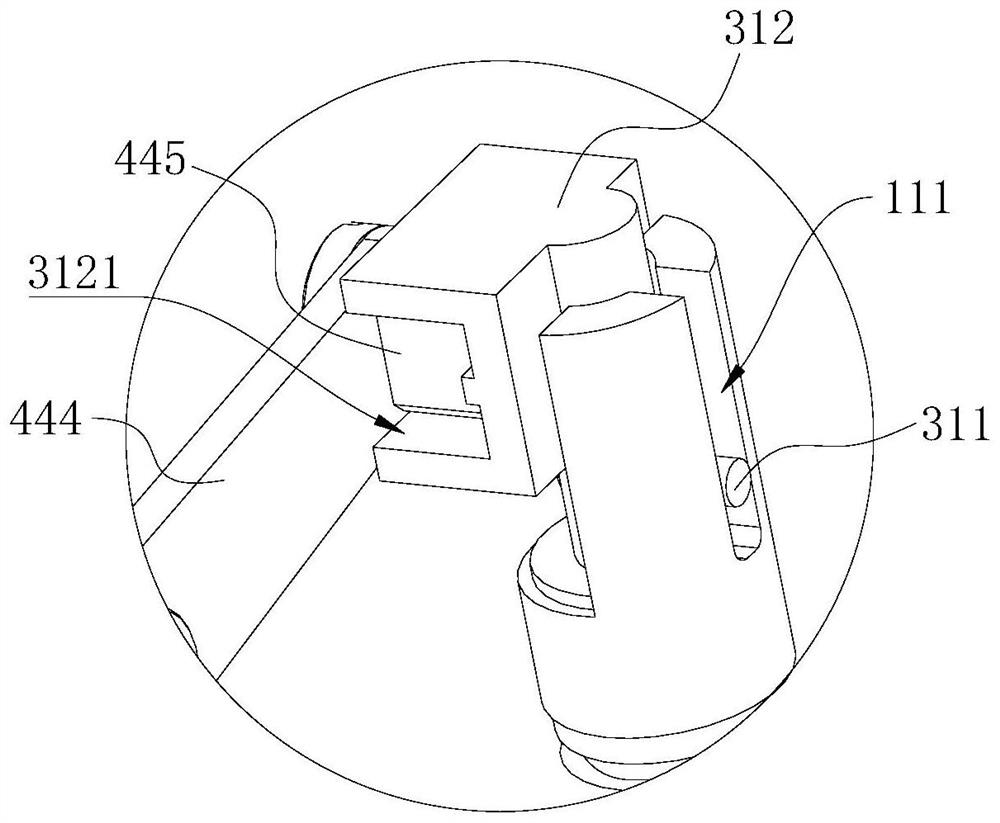

[0074] see image 3 , image 3 for figure 2 An enlarged schematic view at A of the sewing machine 100 is shown.

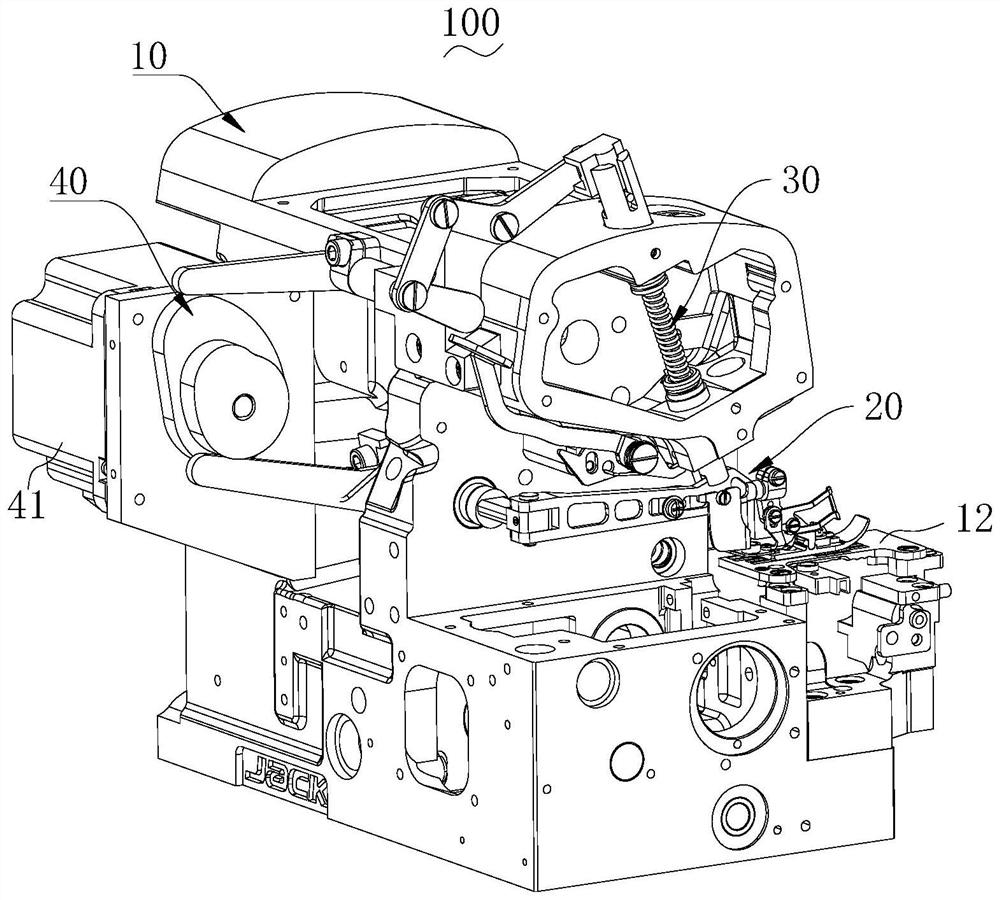

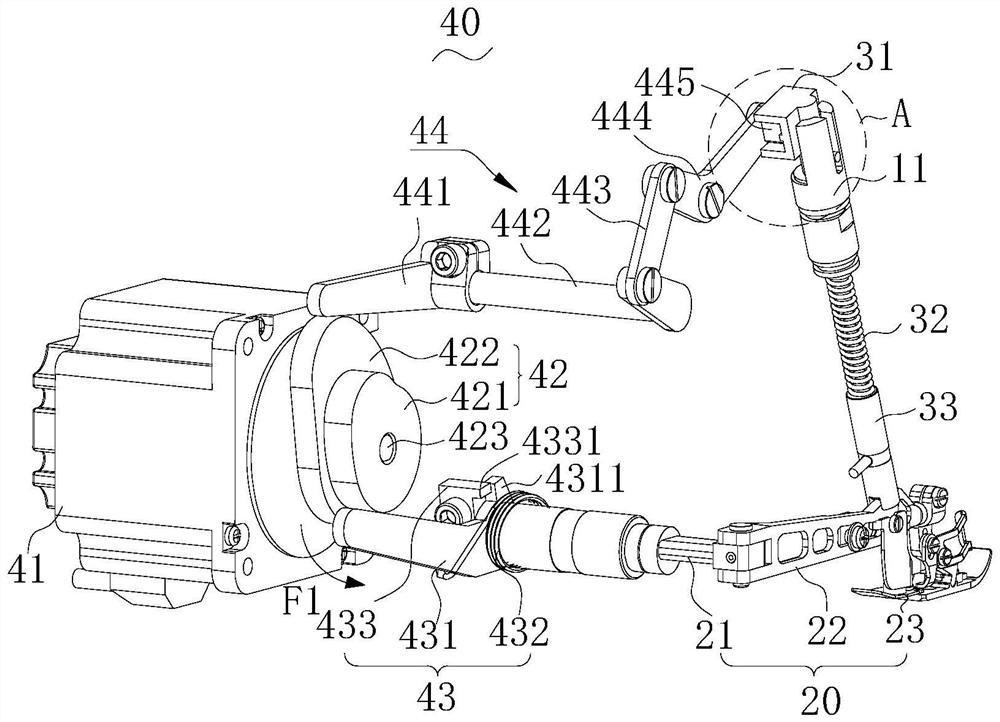

[0075] like figure 1 and figure 2As shown, the joint adjustment mechanism 40 includes a driving source 41 , a driving element 42 , a first driving component 43 and a second driving component 44 . The driving element 42 is connected to the output end of the driving source 41; the first driving element 43 and the second driving element 44 are respectively connected to different areas of the driving element 42, and the first driving element 43 is connected to the presser foot shaft of the presser foot lifting mechanism 20 21. The second drive assembly 44 is correspondingly connected to the pressure regulating elastic member 32 of the presser foot pressure regulating mechanism 30 . The driving element 42 is used to output power to the first driving component 43 and the second driving component 44, and control the first driving component 43 and the second driving...

Embodiment 2

[0114] Please also refer to Figures 6 to 9 , Image 6 It is a schematic structural diagram of the joint adjustment mechanism 40 and other mechanisms of the sewing machine 100 according to another embodiment of the present invention; Figure 7 for Image 6 The illustrated sewing machine 100 is a schematic structural diagram of another perspective after some components are omitted; Figure 8 for Image 6 A schematic diagram of the structure of the drive element 42a in the sewing machine 100 shown; Figure 9 for Figure 8 A schematic diagram of the rotation area of the driving source 41 corresponding to the functional area of the driving element 42a shown.

[0115] The difference from the above-mentioned embodiment is the arrangement of the driving element 42a, and the first driving element 43a and the second driving element 44a are correspondingly adjusted to match the driving element 42a.

[0116] In this embodiment, the drive element 42a is a cam assembly. The cam ...

Embodiment 3

[0131] Please also refer to Figure 10 and Figure 12 , Figure 10 It is a schematic structural diagram of the joint adjustment mechanism 40 and other mechanisms of the sewing machine 100 according to another embodiment of the present invention; Figure 11 for Figure 10 A schematic diagram of the structure of the drive element 42b in the sewing machine 100 shown; Figure 12 for Figure 11 A schematic diagram of the rotation area of the driving source 41 corresponding to the functional area of the driving element 42b shown.

[0132] In the present embodiment, the drive element 42b is an integrally provided cam member. The output end of the drive source 41 is connected to the cam member. The difference from the above two embodiments is that the first area 4211 and the second area 4222 are correspondingly formed in different areas of the cam member, and the first empty area 42112 of the first area 4211 and the second empty area of the second area 4222 are The row ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com