Electric ball valve

A ball valve, electric technology, applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of difficult disassembly and manufacturing, and achieve the effect of not easy to break down and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

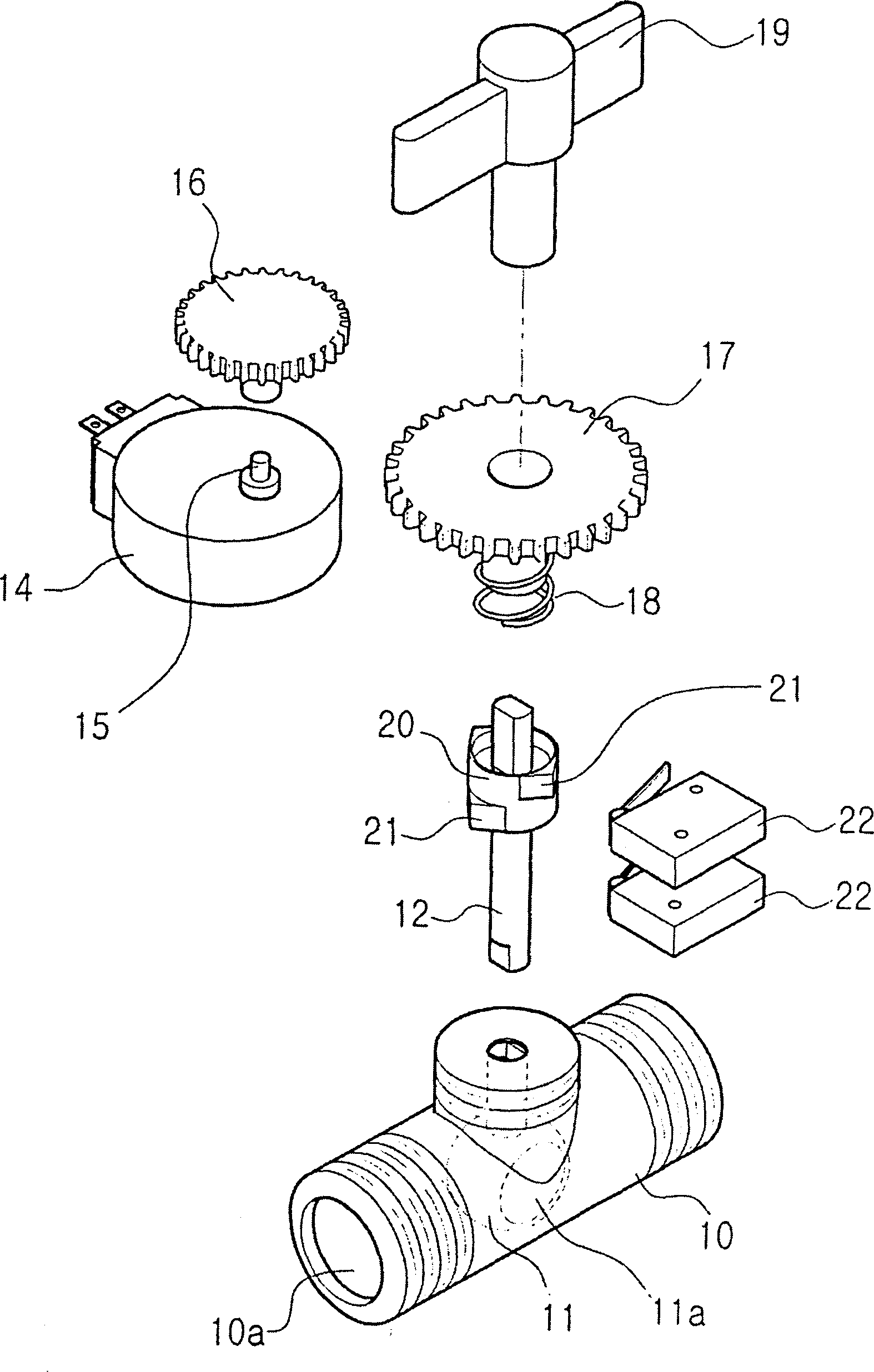

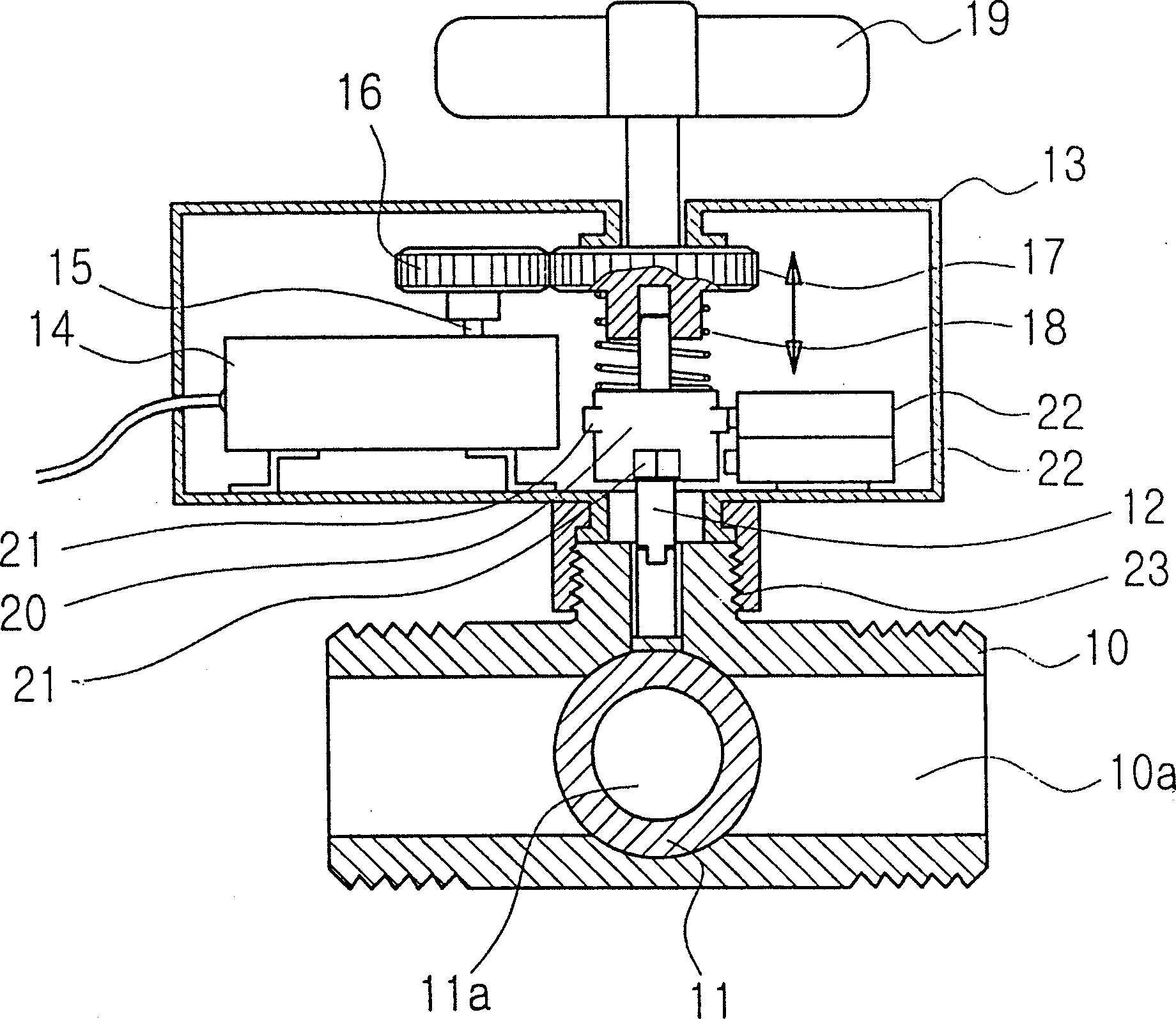

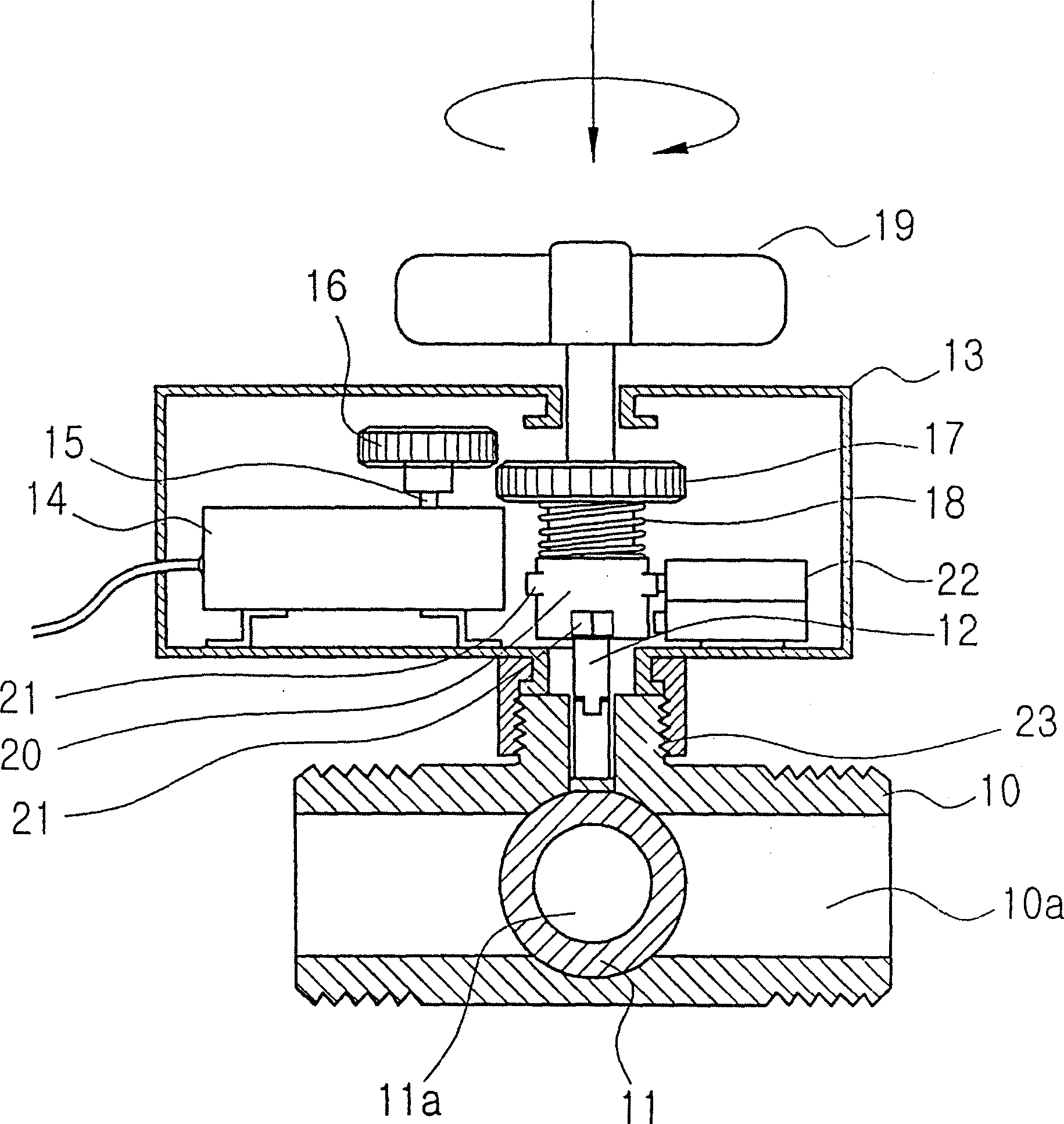

[0015] As can be seen from the drawings, the valve body 10 has a flow path 10a and a ball 11 for opening and closing the flow path 10a. The ball 11 is provided with a hole 11a in the same shape as the flow path 10a, and the valve is opened when the hole 11a is in the same direction as the flow path 10a.

[0016] The sphere 11 is connected to the rotating shaft 12 of the spherical valve. A cam 20 is arranged on the rotating shaft of the spherical valve. A plurality of bosses 2I are formed on the periphery of the cam 20 at intervals of 90 degrees. One side of the cam 20 is provided with a limit switch 22 that completes the on / off action by the boss 2I on the cam 20, and the other side of the cam is provided with a gear motor controlled by the limit switch 22 to rotate.

[0017] Synchronous Geared Motor 14, limit switch 22 and cam 20 are built in motor box 13, and motor box 13 is installed on the upper side of valve body 10, utilizes nut 23 and valve body 10 to connect. The moto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap