Carburizing and quenching process

A technology of carburizing and quenching, which is applied in the field of heat treatment, can solve the problems of poor carburizing and quenching structure, poor process stability, and long process cycle, and achieve the effect of balanced structure, stable structure and good working environment

Pending Publication Date: 2022-07-22

NANJING HIGH SPEED & ACCURATE GEAR GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Poor process stability, prone to poor carburizing and quenching structure, long pr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

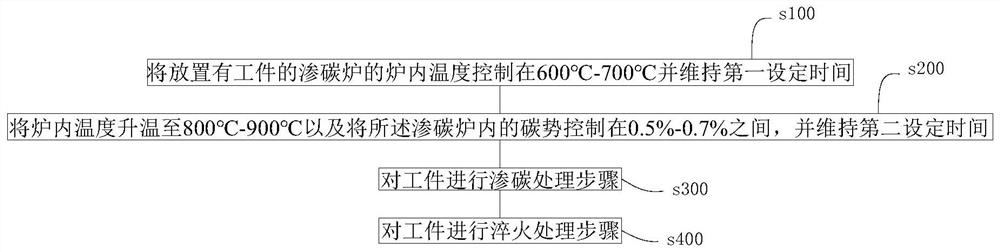

The invention provides a carburizing and quenching process. The carburizing and quenching process comprises the following steps: controlling the temperature in a carburizing furnace in which a workpiece is placed at 600-700 DEG C and maintaining the temperature for a first set time; then the temperature in the carburizing furnace is increased to 800-900 DEG C, the carbon potential in the carburizing furnace is controlled to be 0.5%-0.7%, and the second set time is maintained; then the workpiece is subjected to carburizing treatment; and carrying out quenching treatment on the workpiece. The process is good in stability, the structure of the workpiece is uniform, the workpiece subjected to heat treatment has good microcosmic performance and mechanical performance, and a gear manufactured by the workpiece subjected to heat treatment is excellent in performance and long in service life.

Description

technical field [0001] The invention relates to the field of heat treatment, in particular to a carburizing and quenching process. Background technique [0002] In recent years, with the development of industries such as automobiles, high-speed rail and wind power, high-speed and heavy-duty have become the current key research directions. Whether gear steel can meet the requirements of high quality and high performance has become an urgent problem to be solved. Because the gears are mainly subjected to friction and wear, bending impact and other effects during the working process, the life of the gears is greatly reduced. The use of high-quality alloy gear steel and carburizing and quenching treatment can effectively improve the bearing capacity and service life of the gears. The existing domestic gear steel grades have been difficult to meet the needs of work production, and began to gradually introduce foreign advanced gear steel preparation technology. At present, most he...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C8/22C23C8/02C23C8/80C21D1/18C21D6/00C23F17/00

CPCC23C8/22C23C8/02C23C8/80C21D1/18C21D6/00C21D6/004C23F17/00

Inventor 赵晓春马斐张伟李祥志李朝青

Owner NANJING HIGH SPEED & ACCURATE GEAR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com