Hydraulic control system capable of achieving pre-pressing and main-pressing of clamp

A hydraulic control system and control system technology, applied in the direction of fluid pressure actuation system components, clamping, manufacturing tools, etc., can solve the problem of not being able to arrange two sets of pre-pressing and main-pressing mechanisms at the same time, so as to improve rigidity and improve Machining accuracy, the effect of simplifying the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

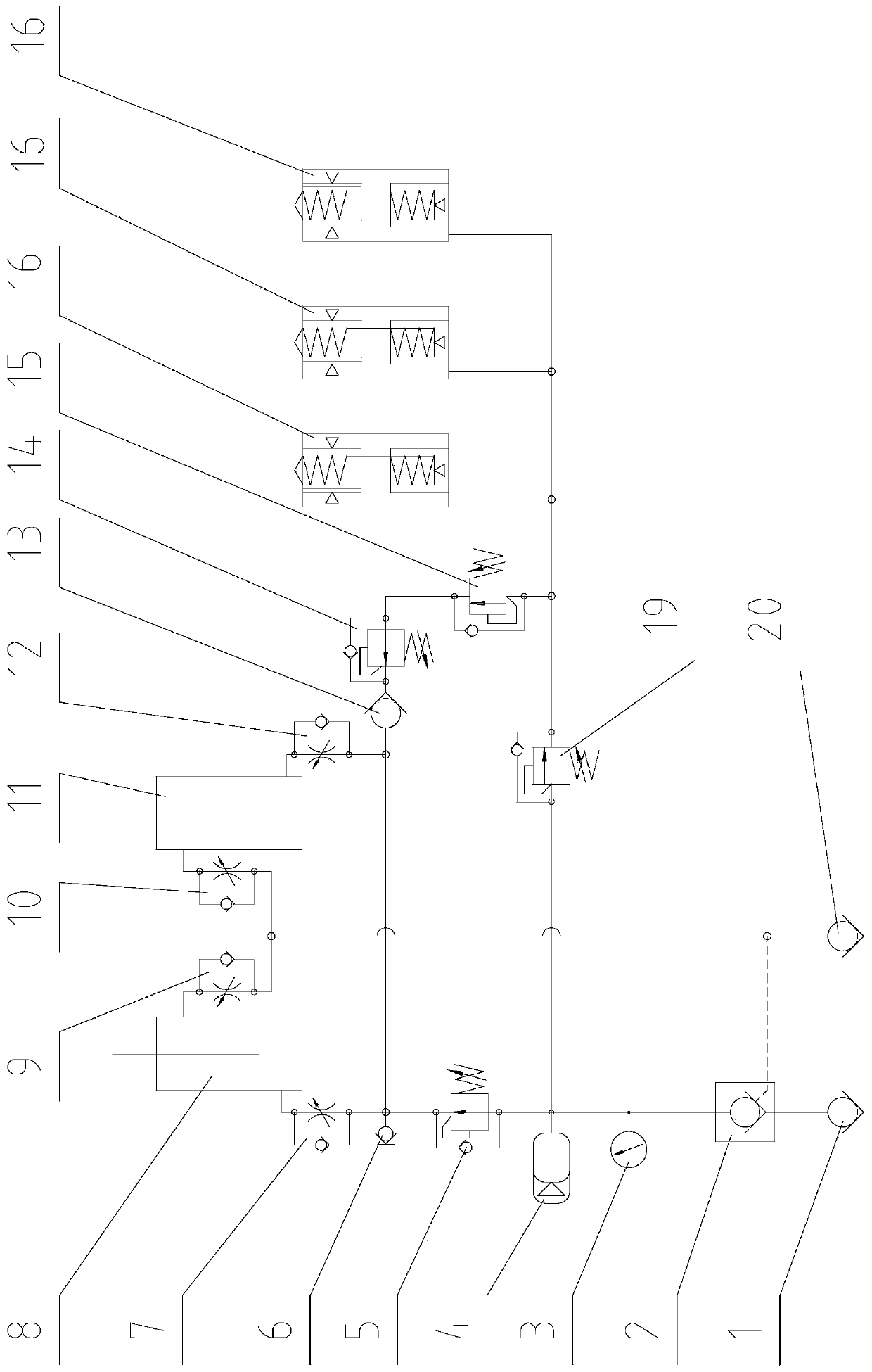

[0019] figure 1 In the middle, it includes the left quick plug connector 1, the hydraulic control check valve 2, the pressure gauge 3, the accumulator 4, the low pressure reducing valve 5, the pressure measuring connector 6, the left one-way throttle valve 7, the left compression cylinder 8, Left one-way throttle valve 9, right one-way throttle valve 10, right compression cylinder 11, right one-way throttle valve 12, one-way valve 13, high pressure reducing valve 14, main pressure sequence valve 15, floating cylinder 16. The sequence valve 19, the right quick plug connector 20 and other components are composed.

[0020] Such as figure 1 As shown, the present invention is a hydraulic control system that can realize the pre-pressure and main pressure of the fixture. It includes a left quick-in connector 1, which is connected to the input end of a hydraulicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com