Air cooling system for horizontal vacuum high-pressure air quenching

An air-cooling system, high-pressure gas technology, applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problems of fast cooling of external workpiece, slow cooling of workpiece, slow cooling of internal workpiece, etc., to improve cooling uniformity, The effect of reducing workpiece deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

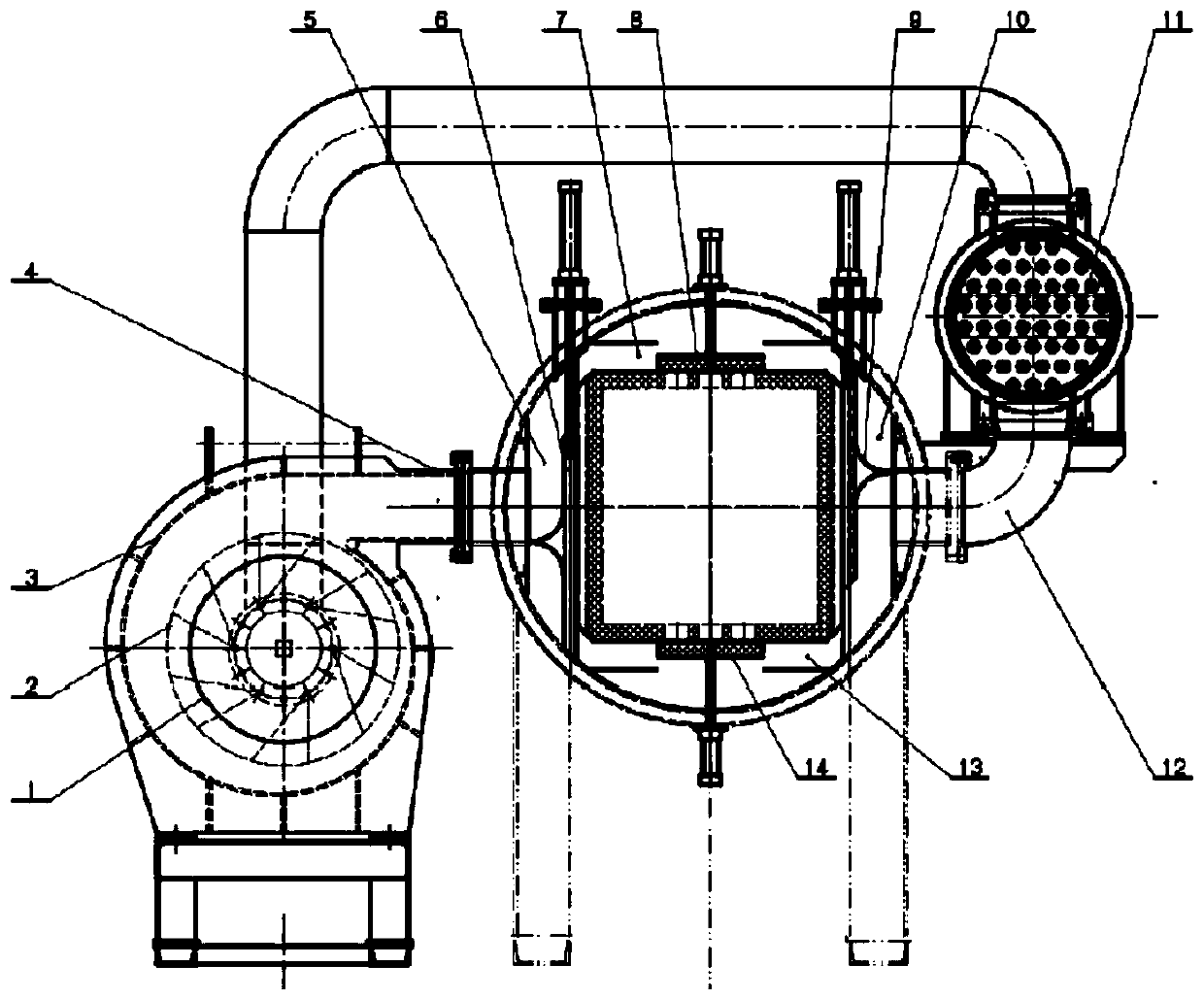

[0022] The air-cooling system for horizontal vacuum high-pressure gas quenching of the present invention, its preferred embodiment is:

[0023] Including fan, impeller, volute, air inlet pipe, air inlet duct, damper I, upper air duct, upper small heat shield, damper II, return air duct, heat exchanger, return air duct, lower air duct, lower small heat shield;

[0024] The impeller is a centrifugal impeller, which is connected with the fan output shaft and installed in a volute, and the volute has an inlet and an outlet;

[0025] One end of the air inlet pipeline is connected with the outlet of the volute, and the other end is connected with the air inlet of the furnace shell;

[0026] Described air inlet channel is surrounded by the inwall of coaming plate, damper 1, furnace shell and forms cavity, and this cavity is connected with described air inlet pipeline, upper air channel and lower air channel;

[0027] The upper air channel is surrounded by a coaming plate, the inner...

specific Embodiment

[0038] figure 1 Shown is the heating process. At this time, the driving cylinders of the upper small heat shield 8 and the lower heat shield 14 are in the ejected state, and the ventilation holes on both sides of the furnace are closed. When heating in this case, since a closed shell is formed in the furnace, it has good heat preservation and heat insulation effects.

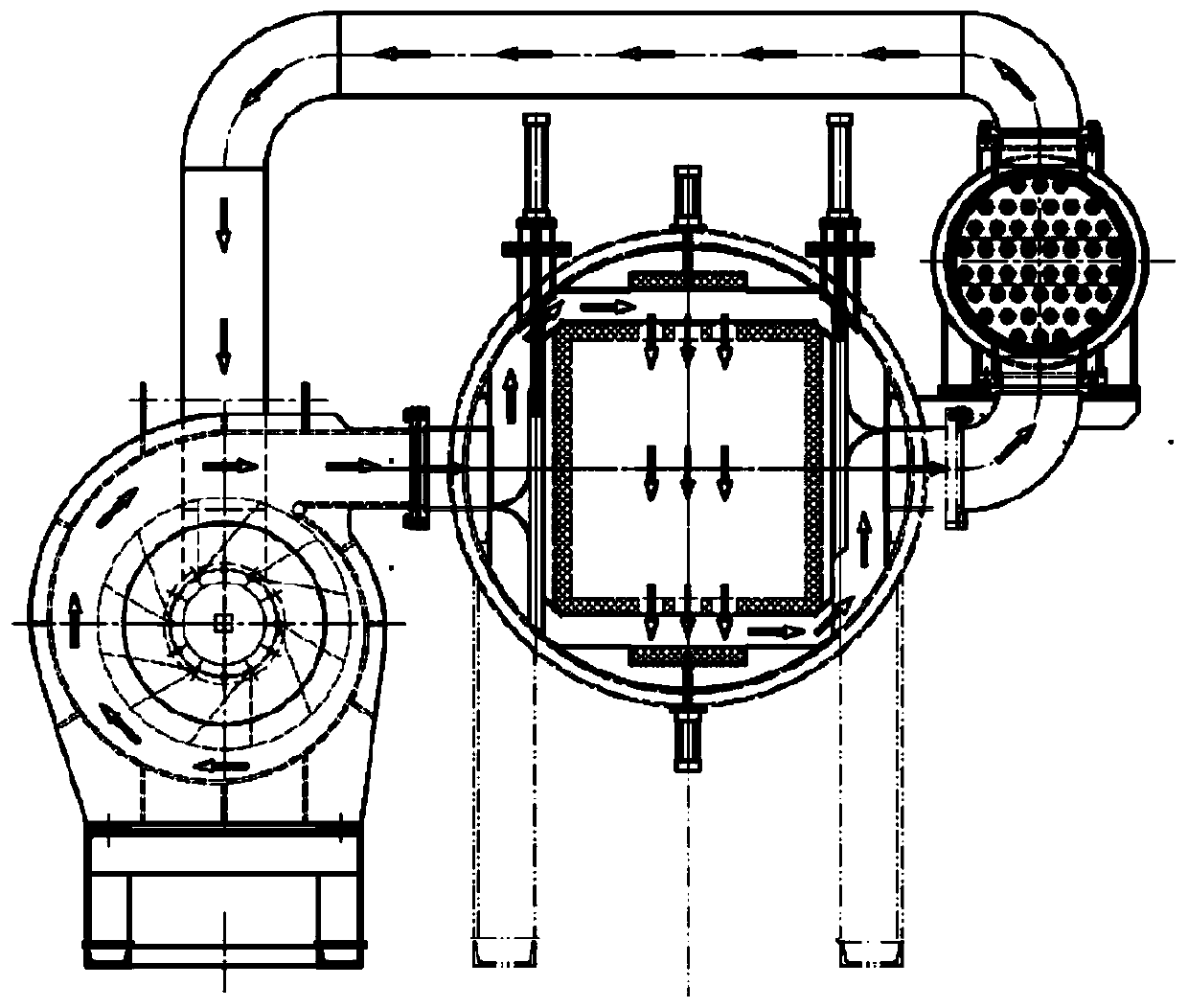

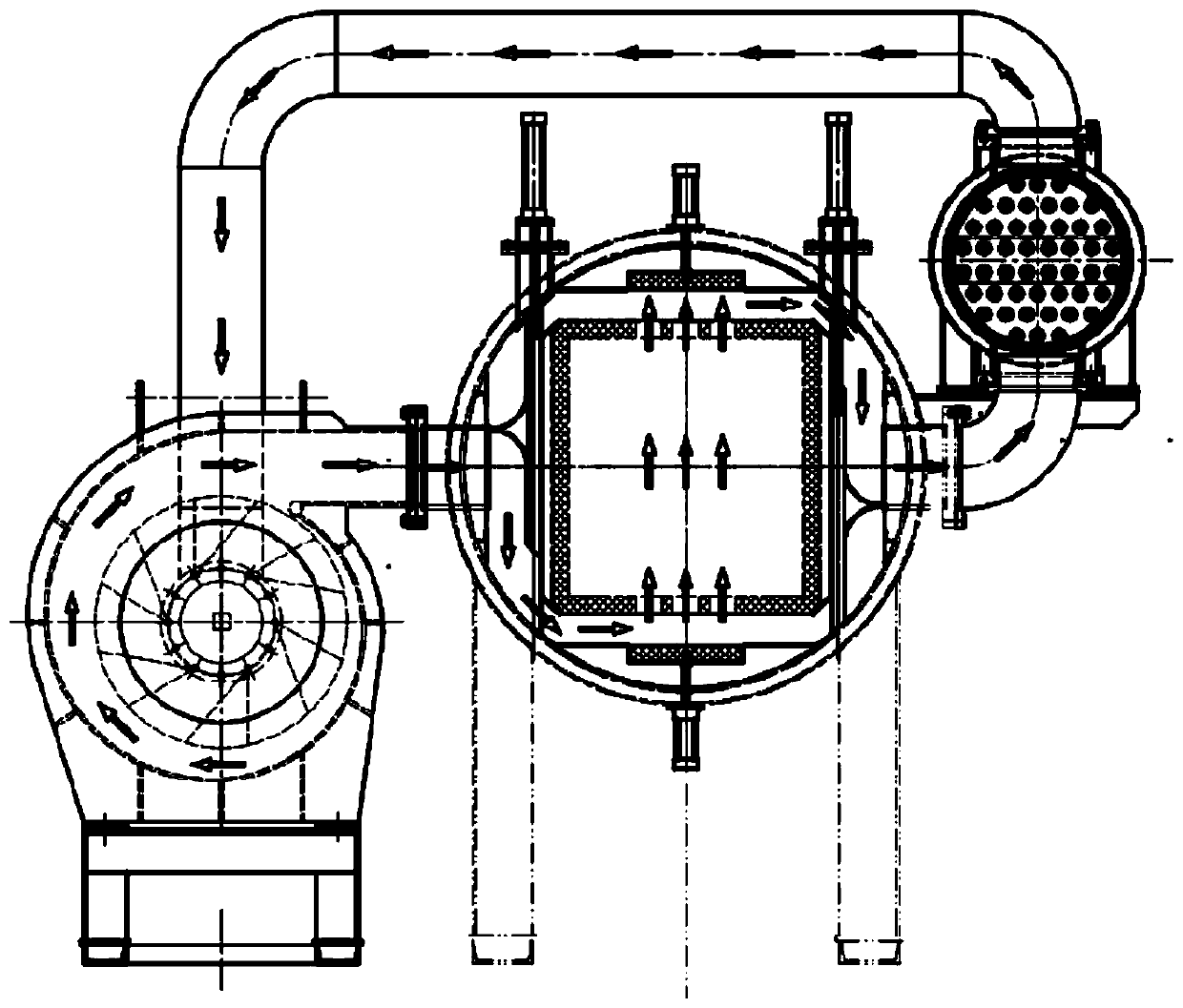

[0039] figure 2 and image 3 Shown is the cooling process, in which the furnace is first filled with high-pressure gas and the fan is started.

[0040] figure 2 Shown is a schematic diagram of airflow cooling from top to bottom. In the figure, the driving cylinders of the upper small heat shield 8, the lower small heat shield 14, and the damper II9 are in the retracted state, and the driven cylinder of the damper I6 is in the ejected state. At this time, the upper small heat shield 8 and the lower heat shield 14 are separated from the furnace, and the ventilation holes on the upper and lower sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com