Air cooling system for improving cooling uniformity of vertical vacuum high-pressure air quenching equipment

A uniform cooling and air-cooling system technology, applied in heat treatment equipment, quenching agent, quenching device, etc., can solve the problems of workpiece deformation, temperature difference between the two ends of the workpiece, uneven structure and performance of the workpiece, etc., so as to reduce the deformation of the workpiece and narrow the temperature difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

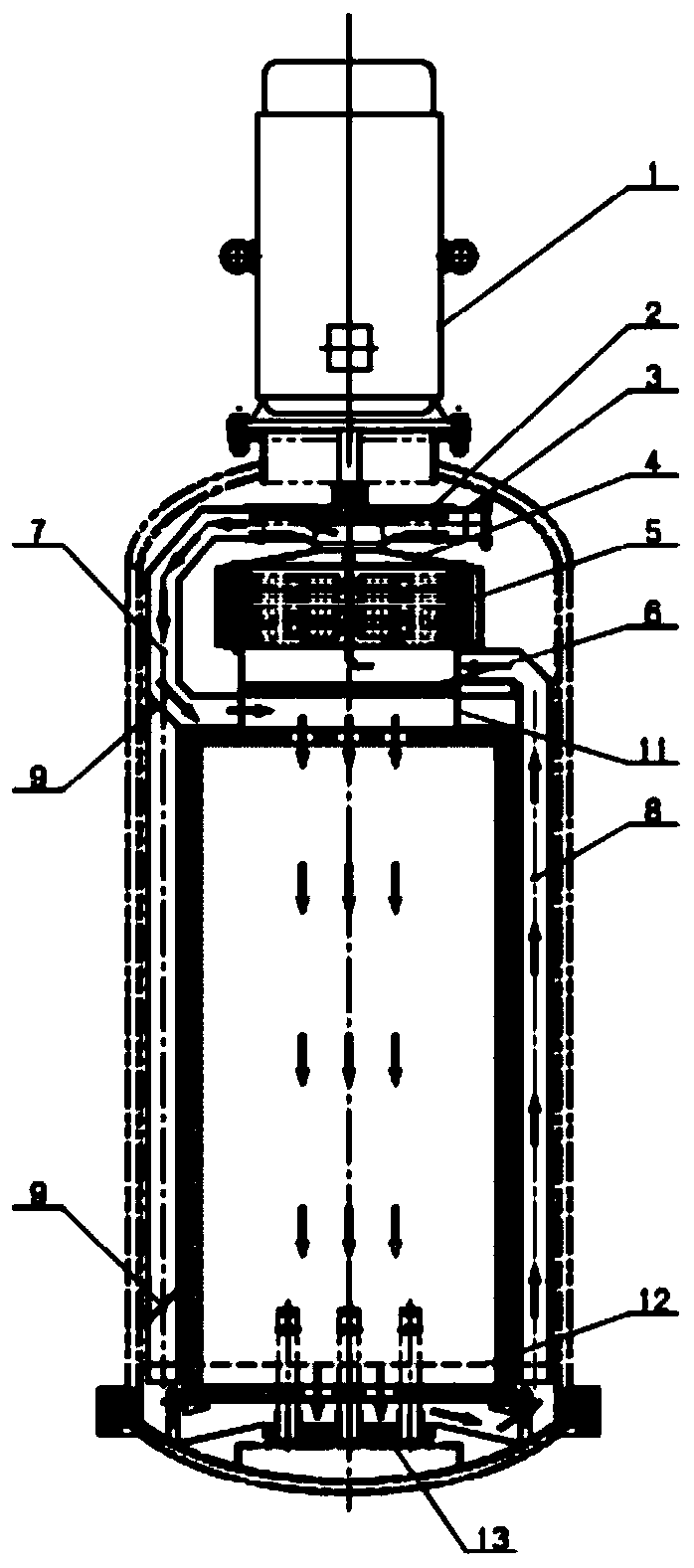

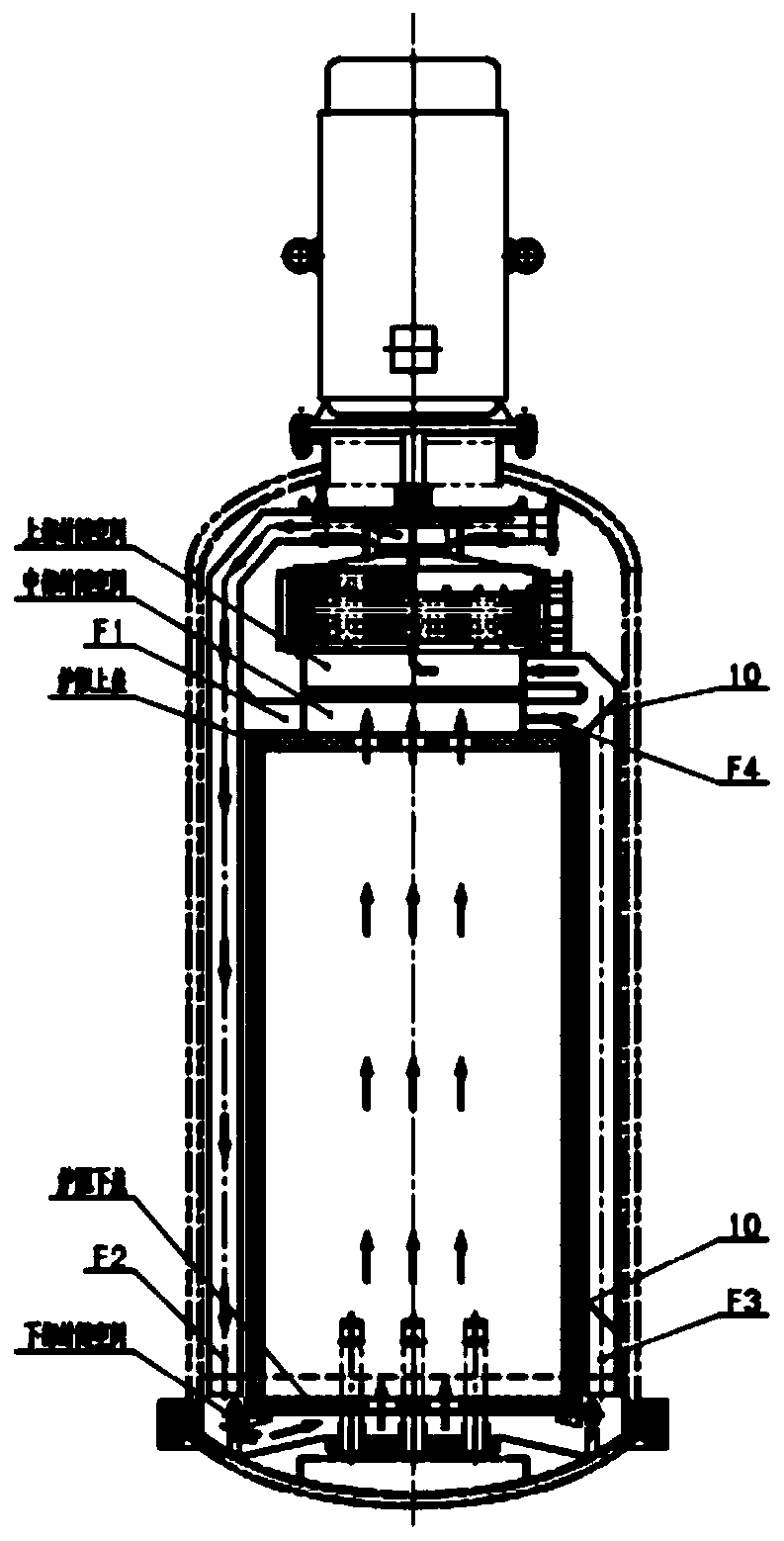

[0018] The air-cooling system for improving the cooling uniformity of vertical vacuum high-pressure gas quenching equipment of the present invention, its preferred embodiment is:

[0019] Including fan, impeller, volute, wind guide cover, heat exchanger, upper small heat shield, air outlet, return air duct, damper I, damper II, upper sealing plate, lower sealing plate, lower small heat shield;

[0020] The heat exchanger, the upper small heat shield and the upper sealing plate form an upper closed space, on which there is an inlet connected to the return air duct, and the gas flowing through the return air duct is closed through the upper part. space into the heat exchanger;

[0021] The upper small heat shield, the upper sealing plate and the furnace upper cover form a closed space in the middle, which is used as an air inlet / return conversion chamber. Entrance;

[0022] The lower sealing plate, the lower small heat shield, the furnace door, the furnace shell and the furnac...

specific Embodiment

[0034] like figure 1 As shown, when the damper I9 in the air outlet duct 7 and the damper II10 in the air return duct 8 are in the position shown in the figure, the air outlet F1 of the air outlet duct 7 is opened, the air outlet F2 of the air outlet duct 7 is closed, and the air is returned at the same time. The air inlet F3 of the channel 8 is opened, and the air inlet F4 of the return air channel 8 is closed. In this case, when cooling, the fan 1 rotates to drive the impeller 2 to rotate at a high speed. After being compressed by the impeller 2, the cooling gas flows out from the outlet of the volute 3, enters the air outlet 7, and enters the closed space in the middle through the air outlet F1. The air hole blows to the workpiece from top to bottom for heat exchange, and then the gas flows out from the air hole in the lower cover of the furnace and enters the lower closed space, enters the air return channel 8 through the air inlet F3 of the air return channel 8, and flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com