Composite hyperbolic corrugated sandwich structure for inhibiting vibration of lubricating oil tank of aero-engine and application of composite hyperbolic corrugated sandwich structure

A technology of aero-engine and sandwich structure, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, and springs made of plastic materials, etc., can solve the problem of poor damping effect, failure to solve the heat dissipation problem of magnetorheological copper coils, and affect vibration reduction Performance and other issues, to achieve the effect of preventing heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

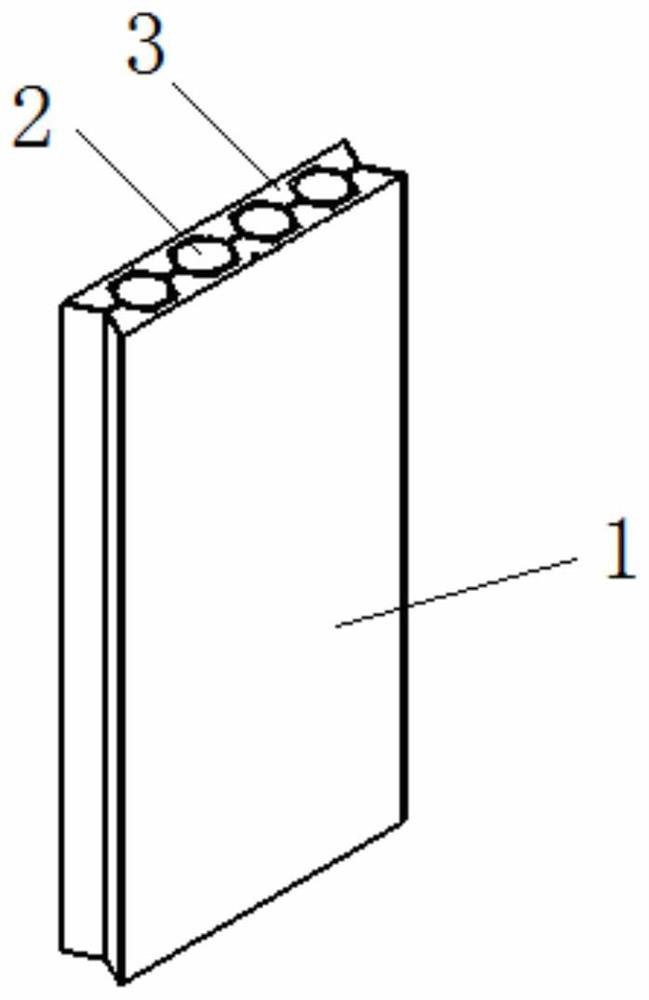

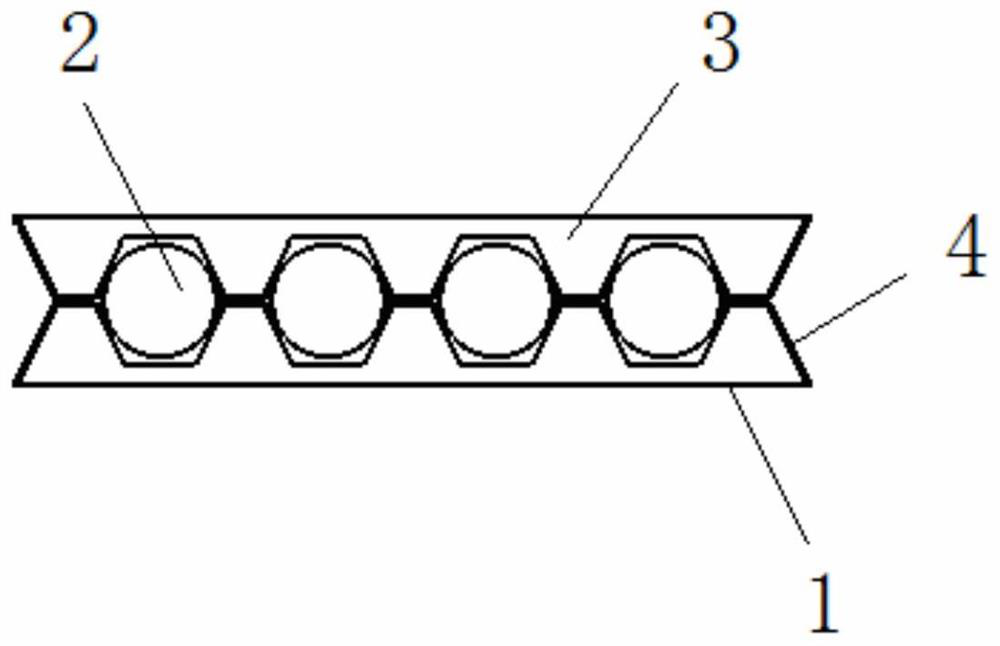

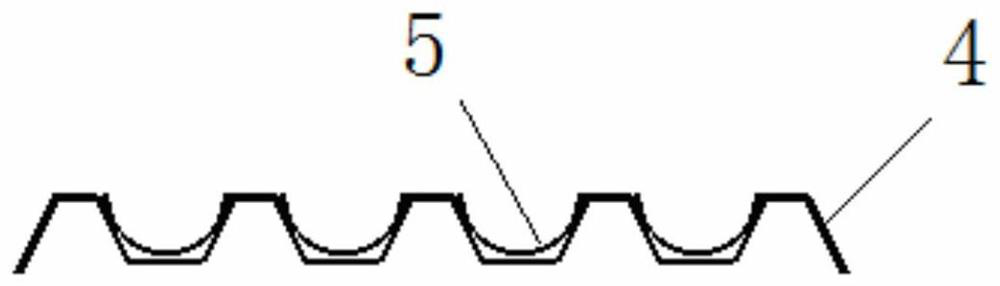

[0026] like Figure 1-4 As shown, a composite hyperbolic corrugated sandwich structure for suppressing vibration of aero-engine oil tank includes two panels 1, two corrugated plates 4 and a plurality of magnetorheological cores 2, the panels 1 and corrugated plates 4 It is made of composite material; two corrugated plates 4 are bonded together, a plurality of mounting holes are formed between the two corrugated plates 4, and the magnetorheological core 2 is placed in the mounting holes; the corrugated The plate 4 is a trapezoidal corrugated plate, and the trapezoidal corrugation forming the mounting hole is provided with a semi-circular arc opening splint 5, and the two semi-circular arc opening splints 5 that are arranged oppositely form a clamp for clamping the magnetorheological core 2; The two panels 1 are respectively arranged on the outside of the two corrugated boards 4, and the panels 1 and the corrugated boards 4 are bonded together by filling with polyester foam 3; t...

Embodiment 2

[0028] like Figure 5 , 6 As shown, the application of the composite hyperbolic corrugated sandwich structure for suppressing vibration of aero-engine lubricating oil tank in Example 1, the composite hyperbolic corrugated sandwich structure 10 is arranged on the metal bracket 11 to form a lubricating oil tank support member , the lubricating oil tank supporting member is respectively fixedly connected with the base and the lubricating oil tank body through bolts, and the base is fixedly connected with the aero-engine casing. The lower part of the metal bracket 11 is two support plates 12 , and the three composite hyperbolic corrugated sandwich structures 10 are respectively arranged between the two support plates 12 and outside each support plate 12 .

[0029]The working principle is as follows: when the supporting parts of the oil tank are vibrated, the piezoelectric ceramic film in the composite material converts the kinetic energy of mechanical vibration into electrical en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com