Production process intelligent management system based on intelligent production

An intelligent management system and production process technology, applied in data processing applications, forecasting, instruments, etc., can solve problems such as difficulty in adapting to the trend of intelligent factory production management, difficulty in allocating and utilizing production processes, and increasing the burden of factory production resources. , to achieve the effect of promoting efficient management, promoting efficient development and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

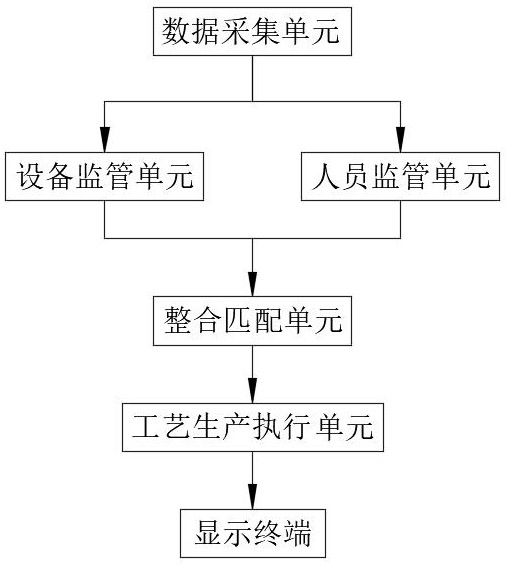

[0045] like figure 1 As shown, a production process intelligent management system based on intelligent production includes a data acquisition unit, an equipment supervision unit, a personnel supervision unit, an integrated matching unit, a process production execution unit, and a display terminal;

[0046] The data acquisition unit is used to collect the operation data information of the equipment in the factory production workshop and the status data information of the employees, and send them to the equipment supervision unit and the personnel supervision unit respectively;

[0047] Among them, the operation data information of the equipment is used to represent a type of data information of the operation status of each production tool and equipment in the production workshop of the factory, and the operation data information of the equipment includes the operation time value, the service year limit value, and the key control value. , the number of failures and the number of...

Embodiment 2

[0058] like figure 1 As shown in the figure, when the equipment supervision unit receives the operation data information of each equipment in the production workshop of the factory, it performs quantitative analysis and processing of the operation difficulty accordingly. The specific operation process is as follows:

[0059] Obtain the operating time value, the annual limit value, the key control value, the number of failures and the number of inspections in the operation data information of each equipment in the factory production workshop, and demarcate them as tyl respectively i , tsl i , kal i , gul i and jal i , according to the formula Czx i =e1×tyl i ÷ (e2×tsl i +e3×kal i +e4×gul i +jal i e5 ), i={1, 2, 3...n}, obtain the operation difficulty coefficient Czx of each device i , where e1, e2, e3, e4, and e5 are the weighting factor coefficients of the operating time length value, the service year limit value, the key control value, the number of faults and the ...

Embodiment 3

[0067] like figure 1 As shown in the figure, when the personnel supervision unit receives the status data information of each employee in the production workshop of the factory, it conducts quantitative evaluation and analysis of skills and quality according to it. The specific operation process is as follows:

[0068]Obtain the actual operation value, qualification value and assessment value in the status data information of each employee in the production workshop of the factory, and demarcate them as scl respectively j , zgl j and khl j , and normalize the actual operation value, qualification value and assessment value, according to the formula Jnx j =f1×scl j +f2×zgl j +f3×khl j , obtain the skill coefficient Jnx of each employee j , j={1, 2, 3...m}, where f1, f2 and f3 are the correction factor coefficients of the actual operation value, qualification value and assessment value, respectively, f1>f2>f3>0, and f1+f2+f3= 5.4081;

[0069] It should be noted that j is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com