High and low voltage ring brush with pressure compensation

A pressure compensation, high and low pressure technology, applied in the field of high and low voltage ring brushes, can solve problems such as burnt slip ring, fire, failure, etc., and achieve the effect of good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

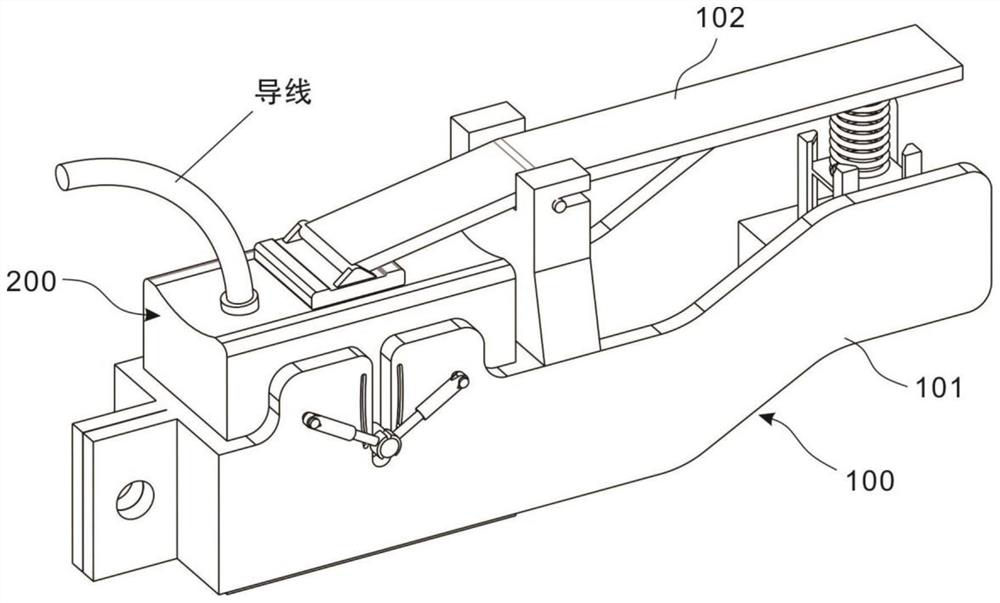

[0032] refer to figure 1 , 2 And 6, for the first embodiment of the present invention, a high-low pressure ring brush with pressure compensation is provided, the brush includes a fixed unit 100 and a carbon brush 200, wherein the fixed unit 100 is used for the carbon brush 200. Limit installation, and apply continuous downward pressure on the carbon brush 200 to ensure that the lower end of the carbon brush 200 can be in continuous and stable contact with the slip ring, so that the high-voltage power supply at the lower part of the electric shovel can be continuously led to the upper part of the electric shovel.

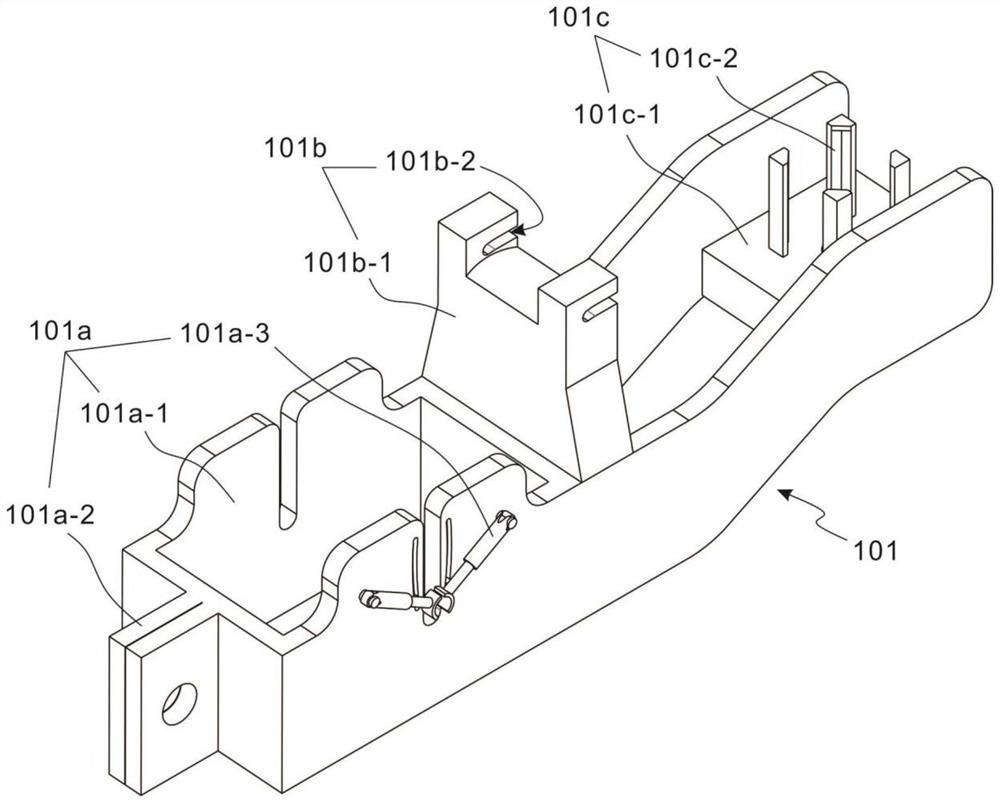

[0033] Specifically, the fixing unit 100 includes a fixing frame 101 and an elastic component 102 disposed on the fixing frame 101. The fixing frame 101 is divided into a first installation area 101a, a stress support area 101b and a second installation area 101c, and the first installation area 101a 2. The second installation area 101c is respectively arranged on b...

Embodiment 2

[0036] refer to Figures 1 to 3 And 6, is the second embodiment of the present invention, this embodiment is different from the first embodiment in that: the first installation area 101a includes a carbon brush placement groove 101a-1, which is vertically arranged in the carbon brush placement groove 101a-1 The outer connecting ribs 101a-2 and the limiting members 101a-3 symmetrically arranged on both sides of the carbon brush placement groove 101a-1.

[0037] Two side walls of the carbon brush placement groove 101a-1 are provided with open grooves 101a-11 in the vertical direction, and the notch of the open groove 101a-11 is located at the top of the side wall of the carbon brush placement groove 101a-1.

[0038]Limiting chutes 101a-12 and connecting posts 101a-13 are also provided on both outer side walls of the first installation area 101a, and the limiting chutes 101a-12 and connecting posts 101a-13 are symmetrically distributed on both sides of the opening slot 101a-11. ...

Embodiment 3

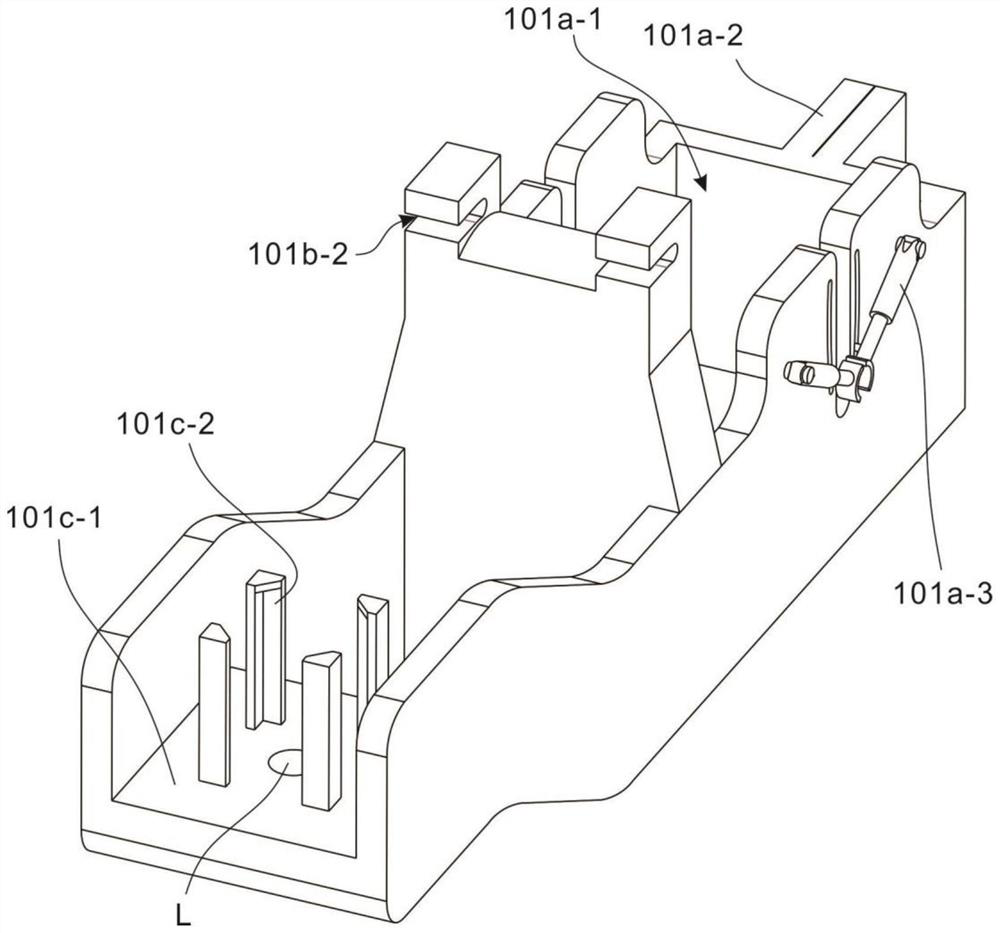

[0050] refer to figure 1 , 4 , 6 and 7, are the third embodiments of the present invention. This embodiment differs from the second embodiment in that: the elastic component 102 includes a force-bearing plate 102a and a pressing head 102b disposed at one end of the force-bearing plate 102a, and The elastic piece 102c is arranged on the other end.

[0051] Rotating columns 102a-1 are provided on the two side walls of the force receiving plate 102a close to the pressing head 102b, and the rotating columns 102a-1 can be fitted in the opening limiting groove 101b-2.

[0052] The elastic member 102c includes a screw rod 102c-1, a mounting plate 102c-2 disposed on the free end of the screw rod 102c-1, and a spring 102c-3 one end of which is mounted on the mounting plate 102c-2; the screw rod 102c-1 can be rotated in the threaded hole L The mounting plate 102c-2 slides in the limit frame 101c-2; the end of the spring 102c-3 away from the mounting plate 102c-2 is connected to the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com