Gluing gun nozzle and gluing system

A technology of gluing and gun nozzle, applied in the field of gluing system, can solve the problems of less glue and lack of glue, more glue, dripping and so on, and achieve the effect of reducing the delay of glue breaking, reducing waste and saving production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

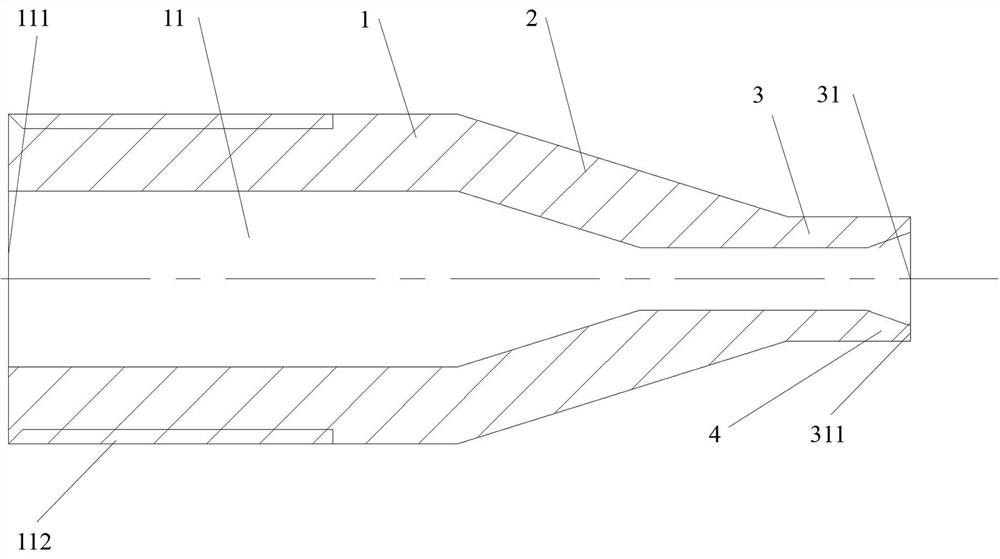

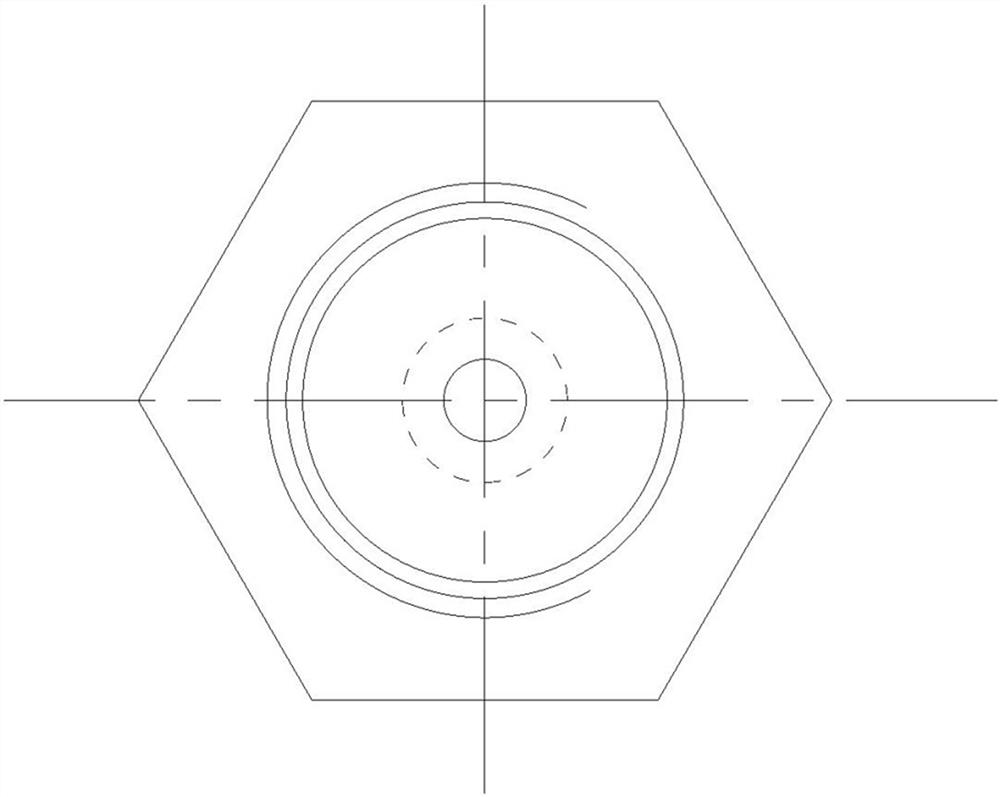

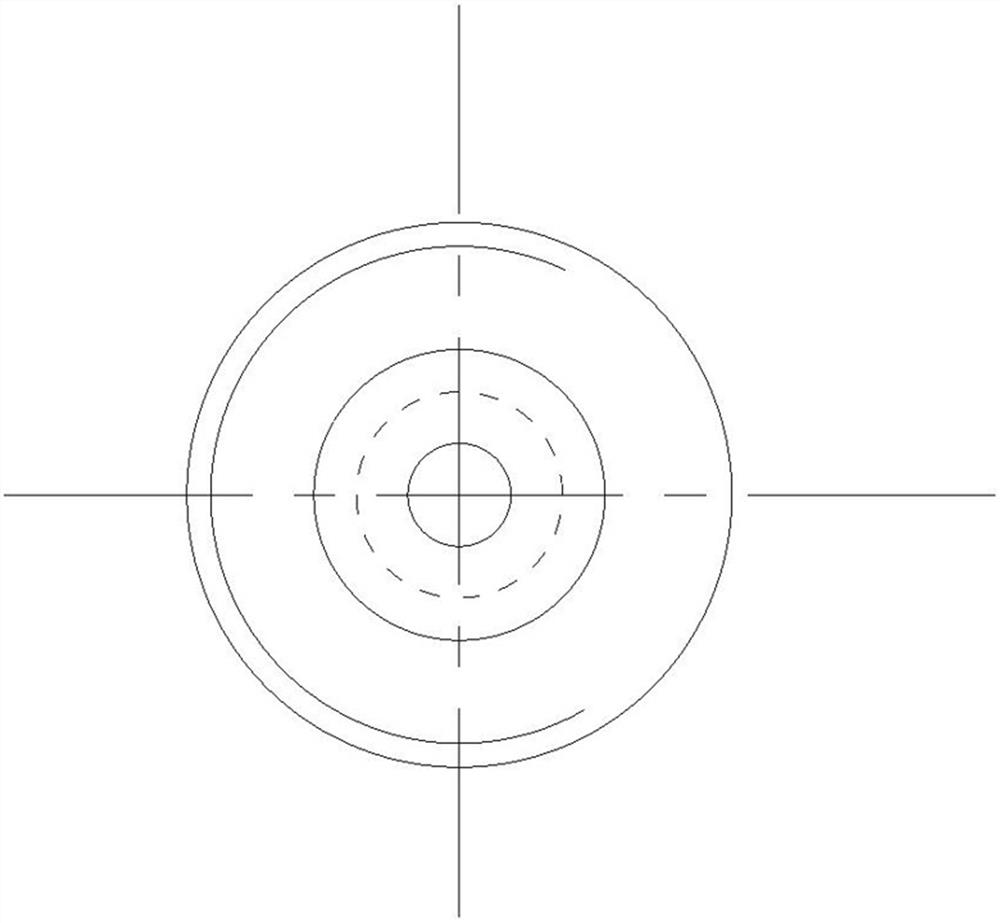

[0026] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the following is combined with the appendix Figure 1-4 and Examples, the present invention will be further described in detail.

[0027] Please also refer to Figure 1-4 , The gluing gun nozzle provided by the present invention includes: a main body 1, the inside of the main body 1 is a glue cavity 11 for accommodating glue; , used for docking with the glue feeding device, so as to input glue from the glue feeding device into the glue cavity 11 through the glue feeding port 111 . The other end of the main body 1 is a transition cone 2 whose outer diameter gradually decreases along the direction away from the glue inlet 111 . And a glue outlet 31 is opened in the glue outlet 3, which is used to apply glue to the glue application surface during the glue application operation.

[0028] In this embodiment, the mouth edge 311 of the glue outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com