Anti-drip inner spiral controllable pressure sprinkler

An internal spiral, anti-drip technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of liquid medicine waste, easy aging, and high cost of use, and achieve the effects of increasing pressure and rotation speed, promoting atomization, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

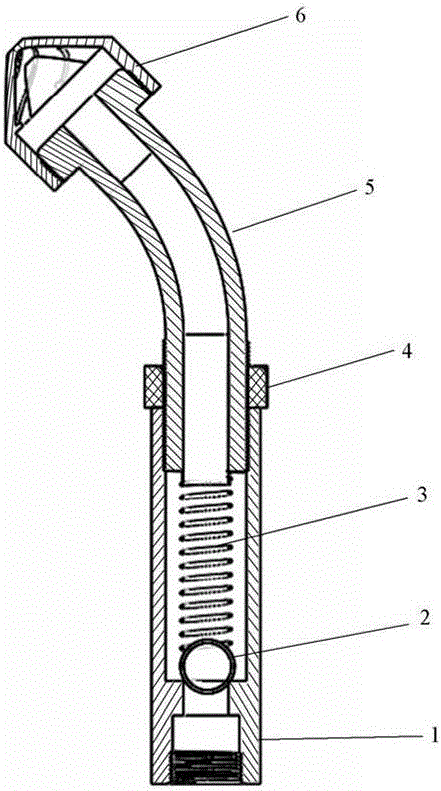

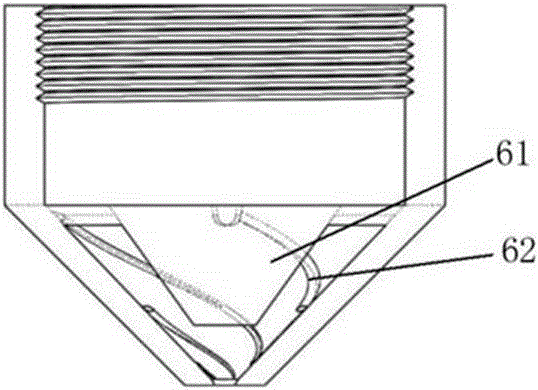

[0021] The present invention can be used as figure 1 The anti-drip internal spiral controllable pressure nozzle shown in the figure includes a low pressure cut-off valve, a pressure regulating pipe (5) and an internal spiral pressure nozzle (6).

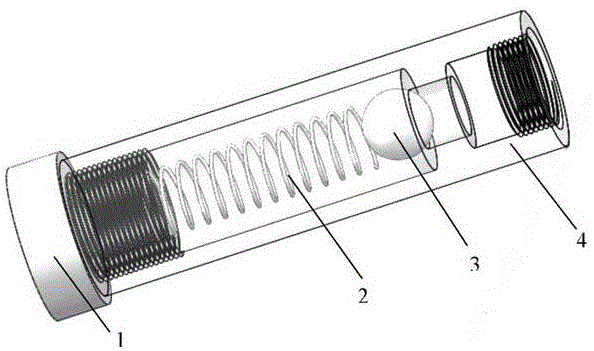

[0022] Such as figure 2 , low-pressure cut-off valve, including outer tube (1), hollow ball (2), spring (3) and adjusting nut (4); the inner side of the end of the outer tube (1) connected to the drug pump is provided with a constriction, and the inner side of the constriction is installed The hollow ball (2), the diameter of the hollow ball (2) is larger than the diameter of the shrinkage but smaller than the inner diameter of the outer tube (1), and the spring (3) is pressed against the hollow ball (2) so that the hollow ball (2) is sealed at the inner end of the shrinkage; The adjusting nut (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com