Air cargo binding device

A technology of air freight and binding device, which is applied in the field of binding equipment, which can solve the problems of cargo damage, easy loosening, and detachment, and achieve the effects of reducing labor intensity, saving time and effort, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

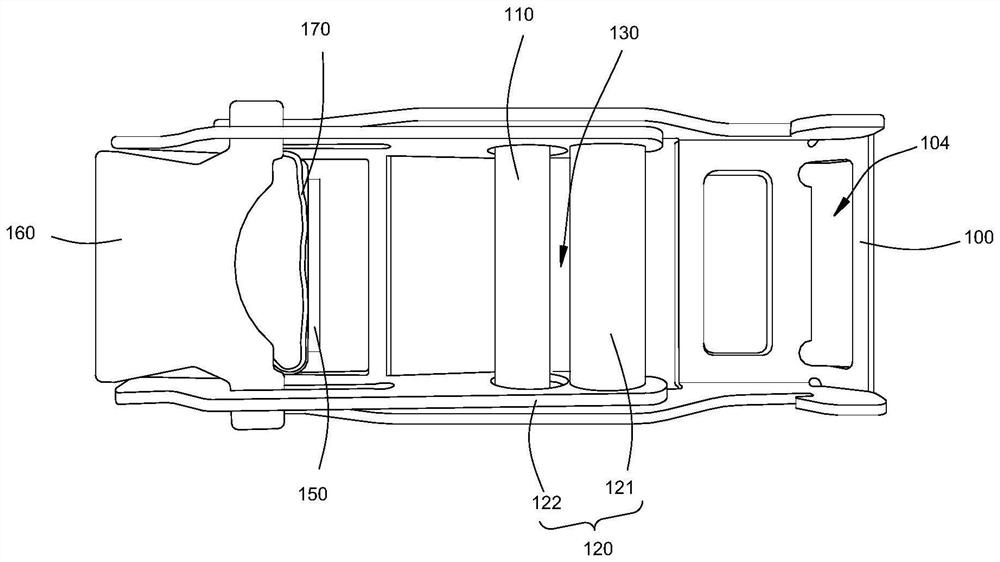

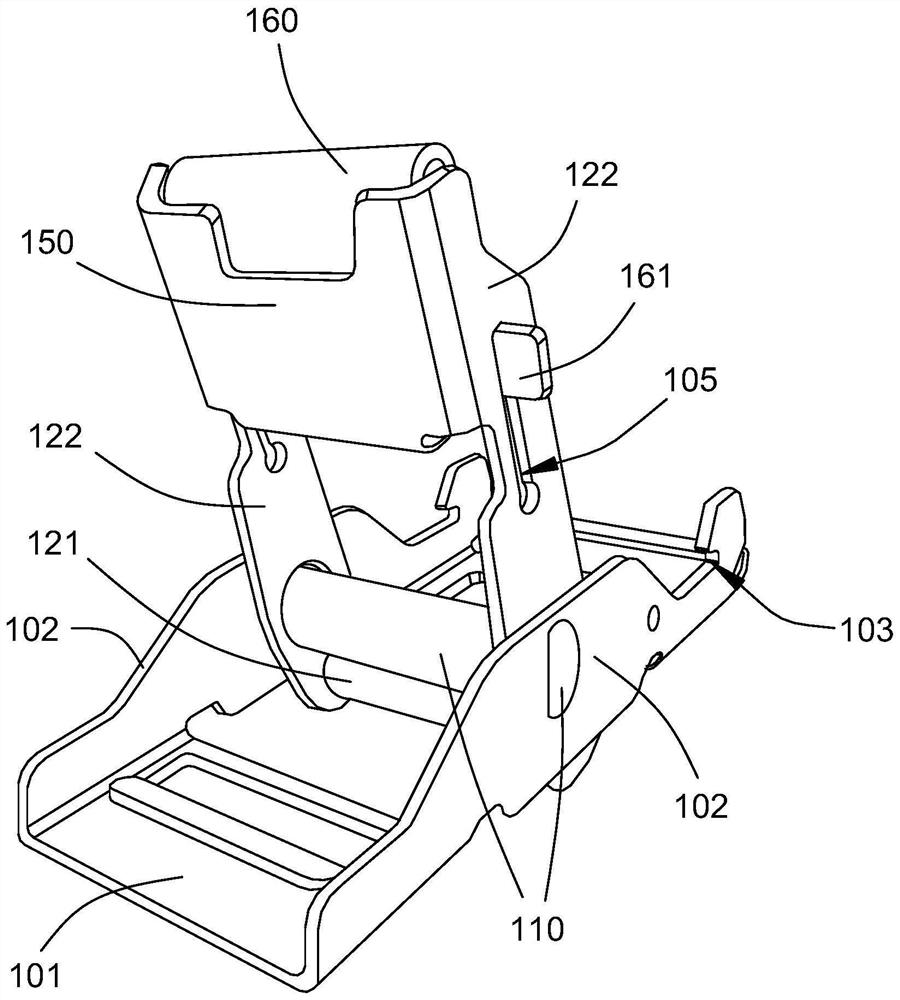

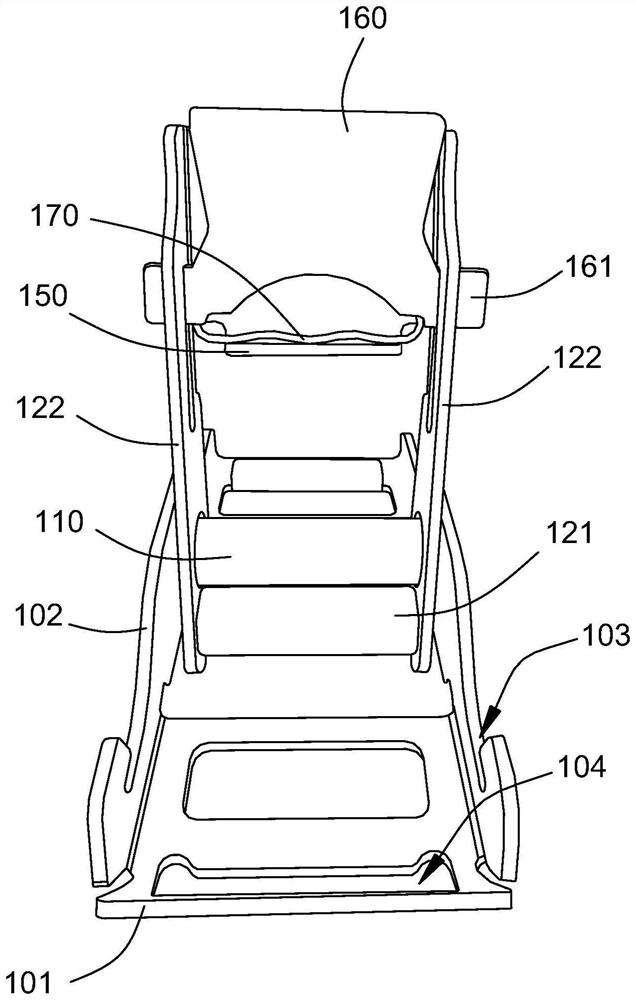

[0035] Please refer to Figure 1 to Figure 5 , this embodiment provides an air cargo binding device, which includes an eccentric shaft 110, a locking buckle 120 and a mounting seat 100 with an installation groove, the eccentric shaft 110 is fixedly installed in the installation groove, and the locking buckle 120 is connected to the eccentric shaft 110 through the eccentric shaft 110. The mounting seat 100 is rotatably connected; when the locking buckle 120 rotates to the first preset position, a first gap 130 is formed between the eccentric shaft 110 and the locking buckle 120 for the strap to pass through; when the locking buckle 120 rotates to the first In two preset positions, a second gap for clamping the strap is formed between the eccentric shaft 110 and the locking buckle 120 .

[0036]In this embodiment, the mounting seat 100 , the eccentric shaft 110 , the locking shaft 121 and the connecting arm 122 are all made of alloy steel. This is because the alloy steel has hi...

Embodiment 2

[0043] Please refer to Figure 1 to Figure 5 , this embodiment proposes based on the technical solution of Embodiment 1: it also includes a switch assembly for connecting the locking buckle 120 and the mounting seat 100 , and the switch assembly includes a limit plate 150 , an elastic member 170 and a locking plate 160 , the two connecting The arms 122 are respectively disposed at both ends of the limit plate 150 , the locking plate 160 is slidably connected with the connecting arm 122 , the elastic member 170 is disposed between the limit plate 150 and the locking plate 160 , and the elastic member 170 is in the compression direction or the extension direction It is consistent with the sliding direction of the locking plate 160 ;

[0044] In this embodiment, the limiting plate 150 and the locking plate 160 are also made of alloy steel, and both have a J shape. The two connecting arms 122 are connected by the horizontal part of the limiting plate 150 . Lock tongues 161 are p...

Embodiment 3

[0046] This embodiment proposes based on the technical solution of Embodiment 1: the mounting seat 100 and the eccentric shaft 110 are integrally formed.

[0047] In this embodiment, the one-piece molding process is mainly used in the manufacturing industry, which means that a certain part is made in one processing, and there is no need to do secondary or more processing, and the whole process can complete the manufacture of a certain part in one process. Integrated molding and non-integrated molding are two different production processes. The manufactured product or part is a whole without any connection. Compared with non-integrated molding, it has better quality, higher strength, superior safety performance, and is more durable. long. The mounting seat 100 and the eccentric shaft 110 can be integrally formed by 3D printing technology, and the structure is stable and firm; the production process is few, and the production cost is low.

[0048] To sum up, the embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com