Steel structure landscape mushroom tree

A steel structure and mushroom technology, applied in special decorative structures, building structures, mechanical equipment, etc., can solve problems such as cumbersome operations, and achieve the effects of reducing workload, reducing the probability of mis-slip, and reducing the center of gravity shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

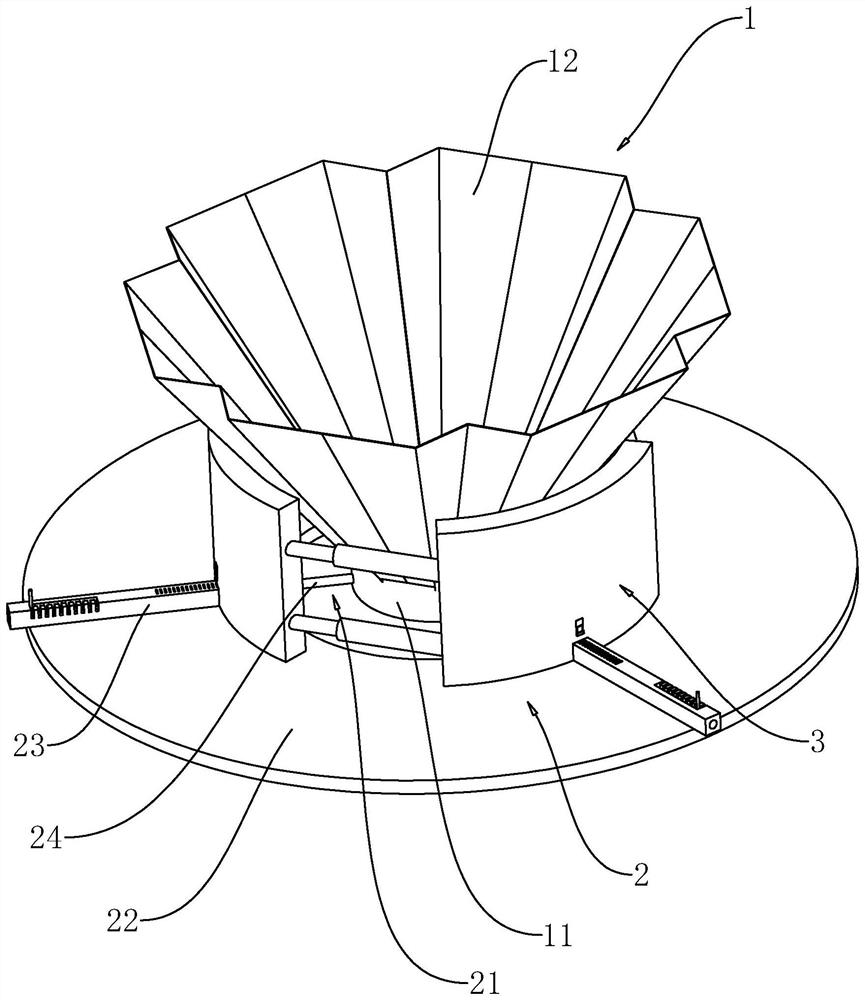

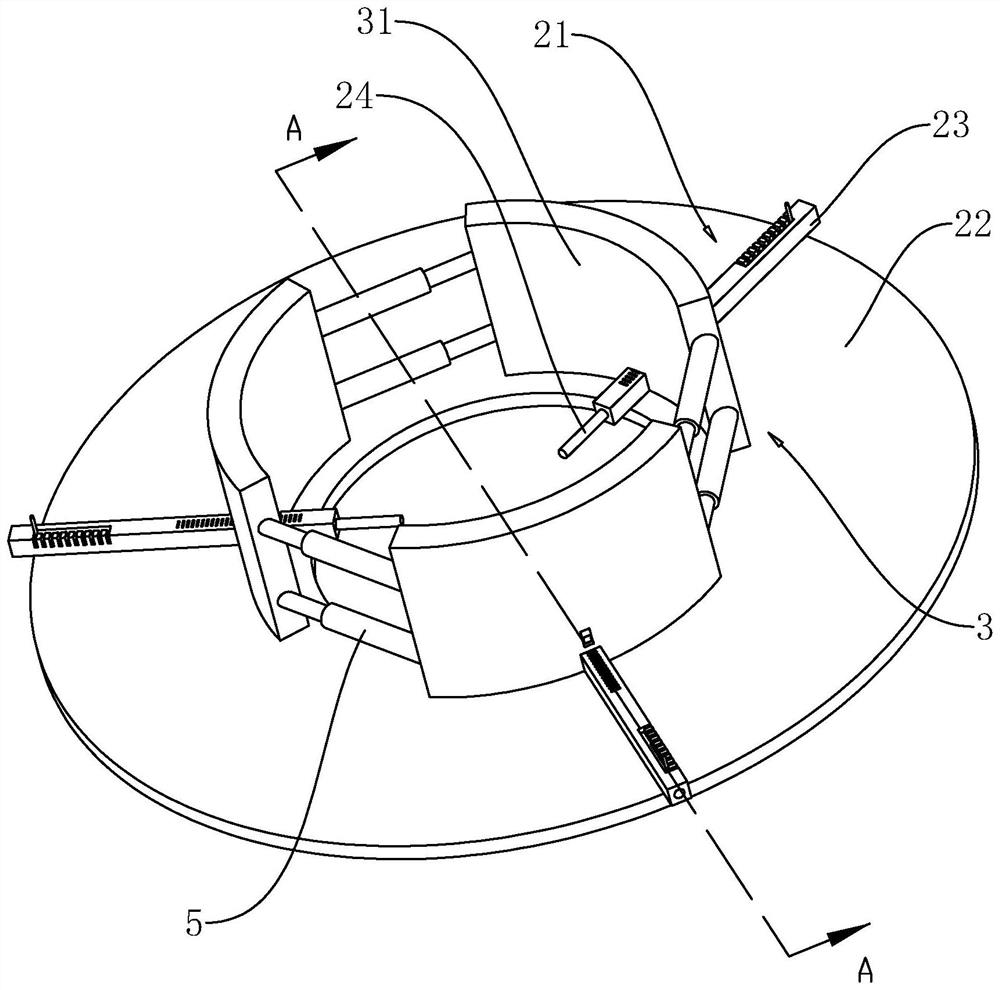

[0032] Attached to the following Figure 1-5 This application will be described in further detail.

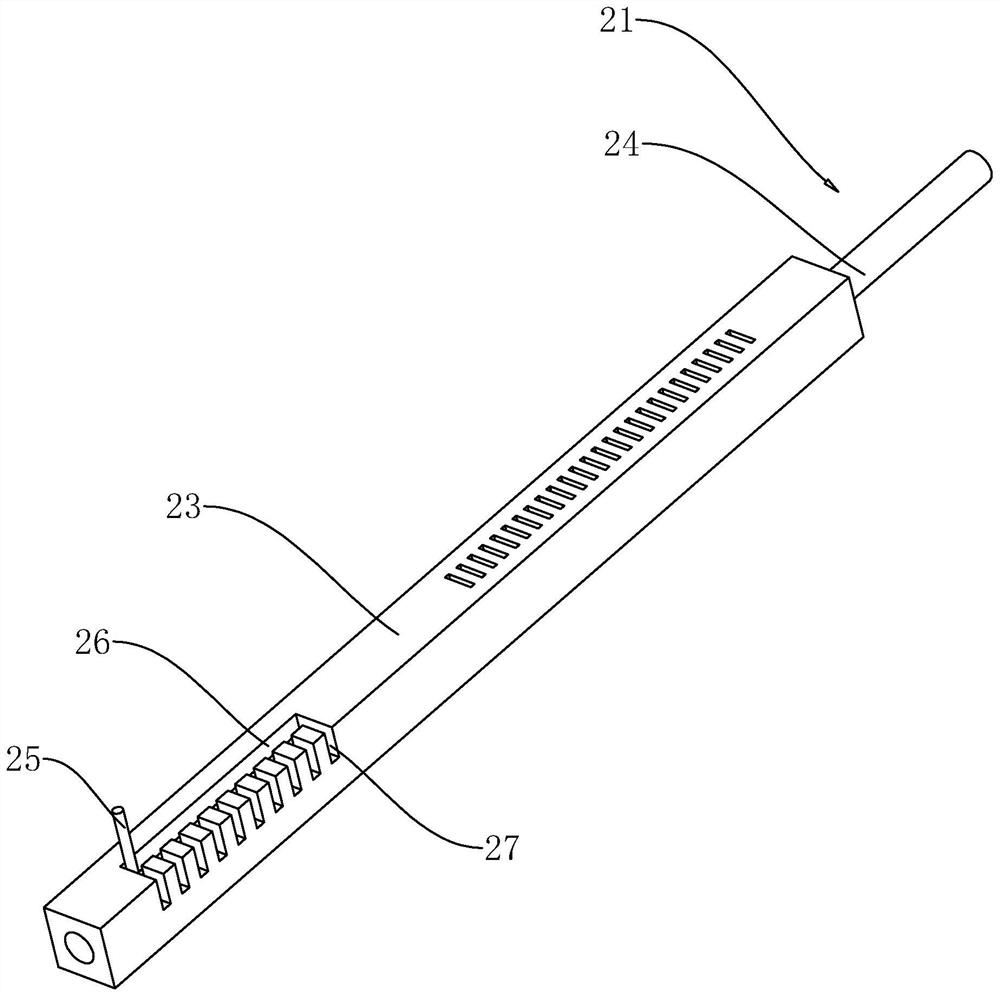

[0033] The embodiments of the present application disclose a steel structure landscape mushroom tree. refer to figure 1, the steel structure landscape mushroom tree includes a trunk assembly and a ceiling assembly 1 installed on the trunk assembly, and the ceiling assembly 1 is installed with a fixing mechanism 2 for limiting the position of the ceiling assembly 1 in the assembly process. The ceiling assembly 1 includes a bottom ring 11 , and the fixing mechanism 2 includes a sliding rod assembly 21 for limiting the position of the bottom ring 11 . The ceiling assembly 1 also includes a mushroom canopy 12 fixedly connected to the bottom ring 11. The bottom ring 11 is in a hexagonal shape, and the end of the mushroom canopy 12 away from the bottom ring 11 gradually spreads into a trumpet shape. The mushroom shed 12 is used to limit the sliding plate assembly 3 .

[0034] ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com