Construction equipment and construction method for wind power tower drum

A technology for construction equipment and wind power towers, which is applied in wind power tower construction equipment and construction fields, can solve problems such as time-consuming, inapplicable tower transmission, and heavy electric equipment weight, and achieve the effect of ensuring the lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

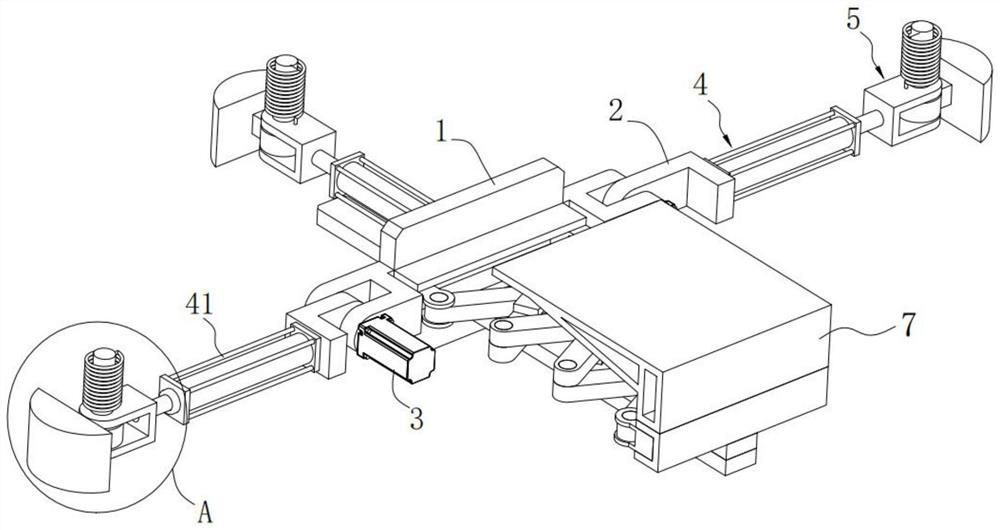

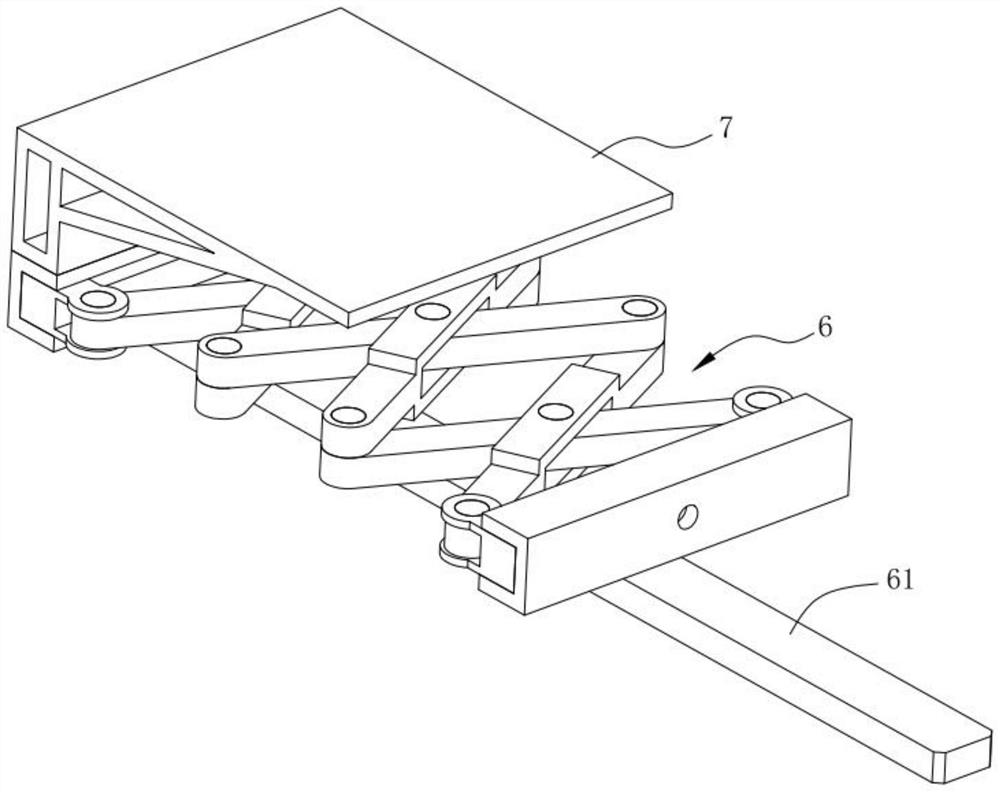

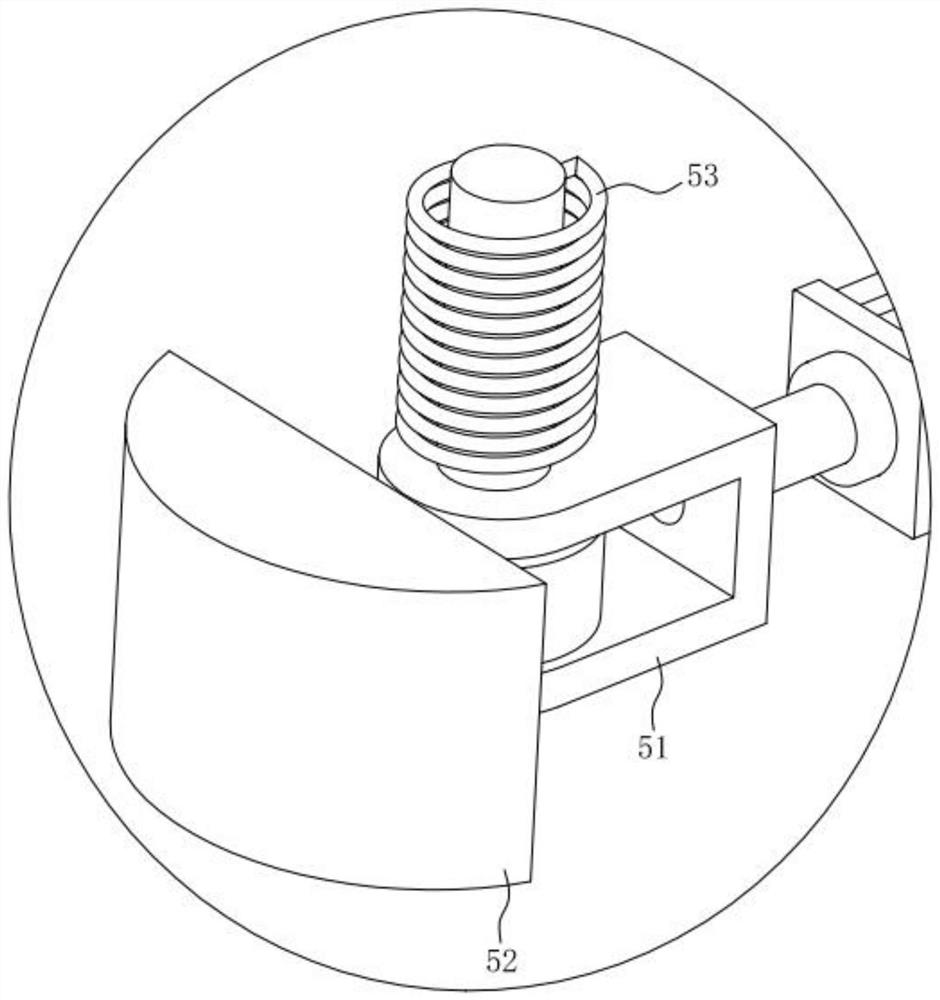

[0025] see Figure 1 to Figure 3 , the present invention provides a kind of technical scheme:

[0026] A construction equipment for a wind power tower, comprising a support frame 1, a base 2, a hydraulic motor 3, a linear drive mechanism 4, an electromagnet assembly 5, a scissor telescopic assembly 6 and a stage 7, wherein:

[0027] The two sides of the support frame 1 are respectively rotatably installed with the base 2, wherein the base 2 is installed through the rotating shaft, and the rotating shaft is rotatably installed on the support frame 1, and the base 2 is fixedly sleeved on the rotating shaft, and then the base 2 is driven to rotate synchronously when the rotating shaft rotates. , and the base 2 is powered with the hydraulic motor 3. Specifically, the hydraulic motor 3 is mounted on the support frame 1 through bolts, and the power output end of the hydraulic motor 3 is powered with the rotating shaft. The base 2 is provided with a linear drive mechanism 4, and supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com